Metformin hydrochloride and glibenclamide capsule and preparation method thereof

A technology of metformin glibenclamide and capsules, which is applied in the field of medicine, can solve the problems of high equipment requirements, and achieve the effects of good dissolution rate, simple process and stable release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

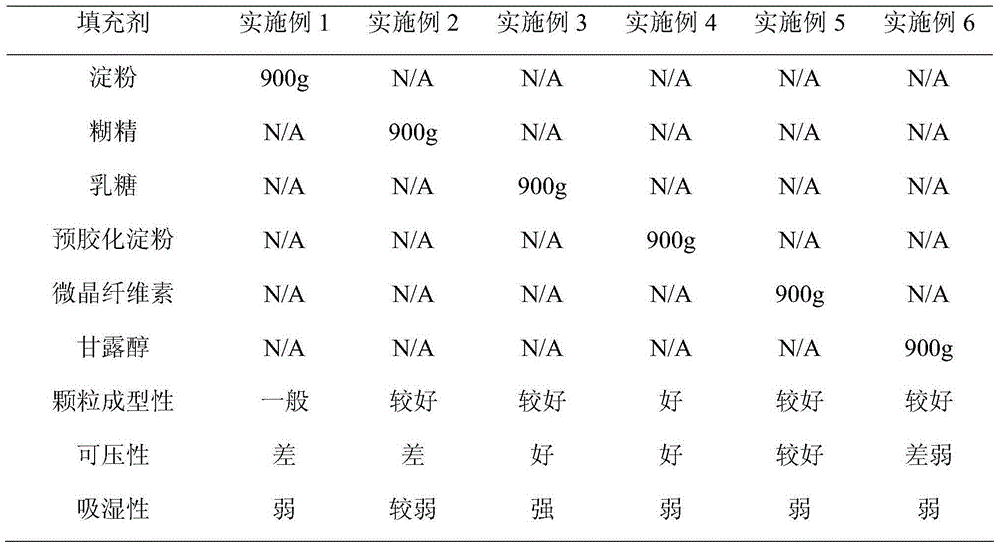

[0038] Metformin hydrochloride, glibenclamide, and fillers were pulverized and passed through an 80-mesh sieve. Weigh 2500 g of metformin hydrochloride, 12.5 g of glibenclamide, and 900 g of filler, and mix well. Take povidone 50g, add 450g dehydrated alcohol, make solution and make binder. The binder is added to the above mixture to prepare a soft material, which is granulated with a 20-mesh sieve. Dry using a fluidized granulation dryer. Use the 20-mesh sieve of the swing granulator to sieve the granules, add 3462.5g of granules and 10g of stearic acid into the mixer, and the mixing time is 10 minutes. Capsule filling with capsule filling machine.

[0039] See Table 1 for the types and amounts of fillers used in Examples 1-6 and related performance indicators.

[0040] As can be seen from the data in Table 1, Example 4 has the best performance.

[0041] The kind and consumption of the filler used in table 1 embodiment 1-6 and relevant performance index

[0042]

Embodiment 7-10

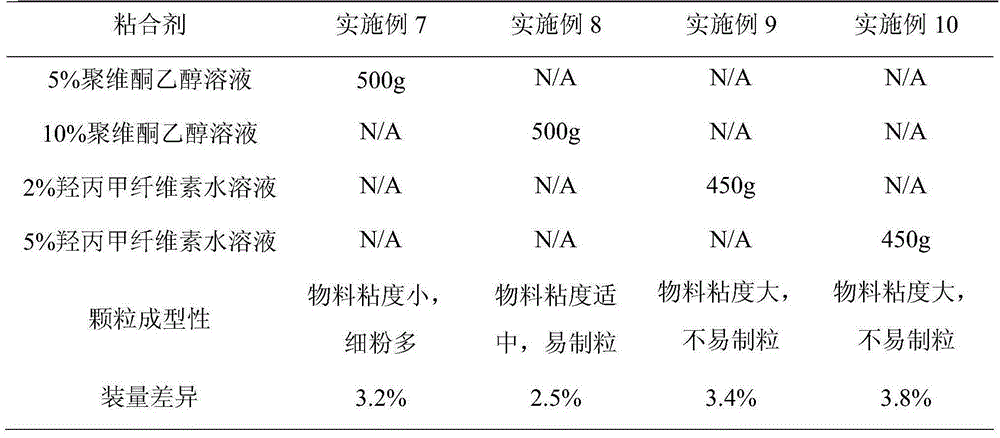

[0044] Metformin hydrochloride, glibenclamide, and pregelatinized starch were pulverized and passed through an 80-mesh sieve. Weigh 2500 g of metformin hydrochloride, 12.5 g of glibenclamide, and 900 g of pregelatinized starch, and mix them evenly. The binder is added to the above mixture to prepare a soft material, which is granulated with a 20-mesh sieve. Dry using a fluidized granulation dryer. Use the 20-mesh sieve of the swing granulator to sieve the granules, add 3462.5g of granules and 10g of stearic acid into the mixer, and the mixing time is 10 minutes. Capsule filling with capsule filling machine.

[0045] See Table 2 for the type and amount of binder used in Examples 7-10 and the properties of the prepared products.

[0046] As can be seen from the data in Table 2, Example 8 has the best performance.

[0047] The type and consumption of the adhesive used in table 2 embodiment 7-10 and the performance of the product prepared

[0048]

Embodiment 11-14

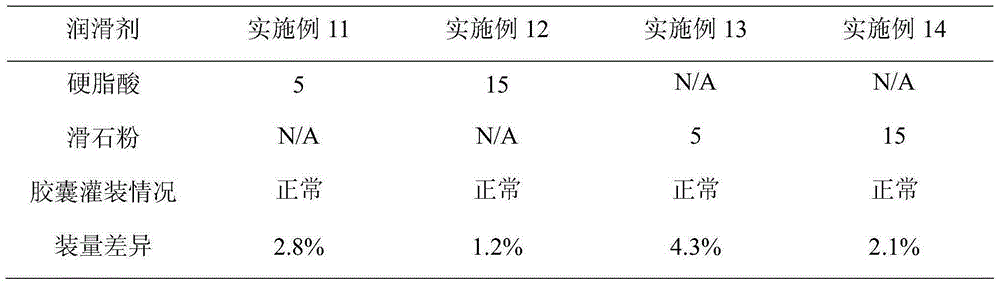

[0050] Metformin hydrochloride, glibenclamide, and pregelatinized starch were pulverized and passed through an 80-mesh sieve. Weigh 2500 g of metformin hydrochloride, 12.5 g of glibenclamide, and 900 g of pregelatinized starch, and mix them evenly. Take povidone 50g, add 450g dehydrated alcohol, make solution and make binder. The binder is added to the above mixture to prepare a soft material, which is granulated with a 20-mesh sieve. Dry using a fluidized granulation dryer. Use a 20-mesh sieve of a swing granulator to sieve the granules, add 3462.5 g of granules and a lubricant into the mixer, and the mixing time is 10 minutes. Capsule filling with capsule filling machine.

[0051] The types and amounts of lubricants used in Examples 11-14 and the properties of the prepared products are shown in Table 3.

[0052] As can be seen from the data in Table 3, Example 12 has the best performance.

[0053] The type and consumption of the adhesive used in table 3 embodiment 11-14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com