Method for manufacturing nylon 6

A manufacturing method and technology of polyamide, applied in the field of manufacturing polyamide 6, can solve the problems of undisclosed polyamide crystallinity improvement, etc., and achieve the effects of improving rigidity, crystallinity, and heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

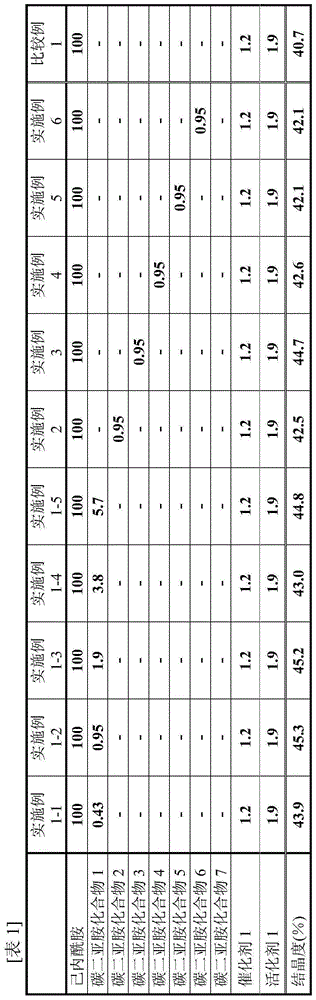

[0059] Embodiment 1-1~1-5, 2~6, comparative example 1

[0060] The raw material components shown in Table 1 were charged to the reactor. It should be noted that for the raw material components, the raw material composition A formed by mixing caprolactam and the catalyst and the raw material composition B formed by mixing caprolactam, activator and carbodiimide compound are prepared in advance, and the two are equal amounts (parts by weight) ) mixed into the reactor. The raw material composition was used after being melted at 100°C. The polymerization time in the reactor was set to 30 minutes, and the polymerization temperature was set to 150°C. After the polymerization time has elapsed, the polymer is quickly withdrawn from the reactor. The crystallinity of the obtained polymer was measured by using a differential scanning calorimeter DSC6220 manufactured by Seiko Instruments at a heating rate of 20°C / min, and the heat of fusion of the crystal part obtained from the obtaine...

reference example 3

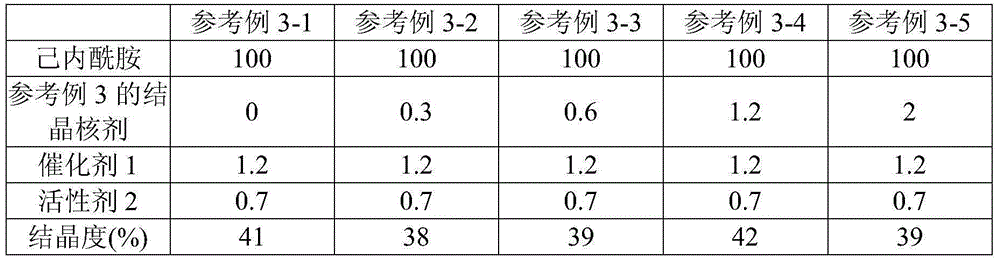

[0068] The result of reference example 3

[0069] The crystal nucleating agent of Reference Example 3 was dissolved in the caprolactam solution, so Reference Examples 3-1 to 3-5 were prepared according to the ratio in Table 3. The results of Reference Example 3 are listed in Table 3 as Reference Examples 3-1 to 3-5. Wherein, Reference Example 3-1 is a blank test. The blending amount values in Table 3 are parts by weight.

[0070] [table 3]

[0071]

[0072] In Reference Example 3, the mixing amount of the crystallization nucleating agent was changed. According to the results in Table 3, it can be seen that the crystallinity of the polymer decreased relative to the blank, or only slightly increased, and there was no crystallinity improving effect.

[0073] On the other hand, as shown in Table 1, it can be seen from the results of Examples that if a carbodiimide compound is used as a crystallinity improving agent, the crystallinity of polyamide 6 obtained by the so-calle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com