Sectional type extensible insulating cylinder

An insulating cylinder and segmented technology, which is applied in the field of transformer manufacturing, can solve the problems of increasing the arc radius of the equalizing ball, making it difficult to find replaceable parts, etc., and achieve the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

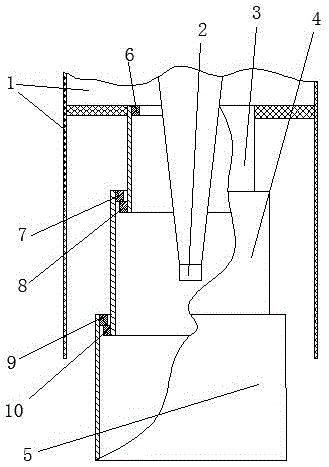

[0030] The installer puts the third insulating cylinder part 5, the second insulating cylinder part 4 and the first insulating cylinder part 3 on the side of the raised base 2 in sequence, and fixes the first insulating cylinder part 3 on the raised base 1 with an insulating screw, Put the lifting seat 1 vertically, pull the second insulating cylinder 4 and the third insulating cylinder 5 to the maximum stroke, at this time, the insulating cylinders are connected to each other through the sleeve ring, and the pressure equalizing ball 2 is covered, and the installation is completed .

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com