Rolling bearing fault prediction method based on wavelet principal component analysis

A rolling bearing and component analysis technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as high time complexity of algorithms, loss of signal frequency information, and easy occurrence of endpoint effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Wavelet packet analysis is a signal processing method based on the time-frequency domain. Its good local optimization properties make wavelet packet analysis show multi-scale and ability to detect sudden changes in the processing of non-stationary signals. research hotspot.

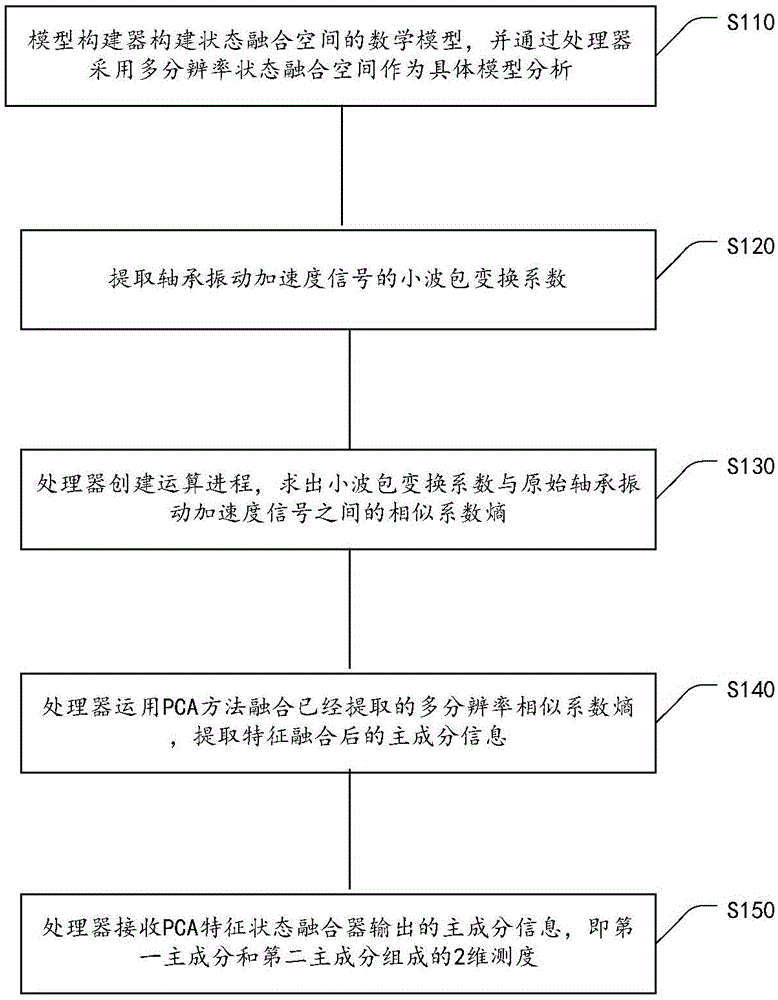

[0046] This embodiment provides a processing flow of a rolling bearing fault prediction method based on wavelet-PCA technology as follows figure 1 As shown, the following processing steps are included:

[0047] Step S110, the model builder constructs the fusion feature space, and uses the multi-resolution state fusion space as a specific model analysis through the processor.

[0048] The mathematical model of the above-mentioned state fusion space can be expressed in the following form: assuming a time-domain signal f(t), t∈N, after transformation in the Euclidean space, F(λ)=Γ[f(t)] can be obtained, where , λ={λ 1 ,...λ i ,...λ n} is an n-dimensional Cartesian set, and the n-dimensional Carte...

Embodiment 2

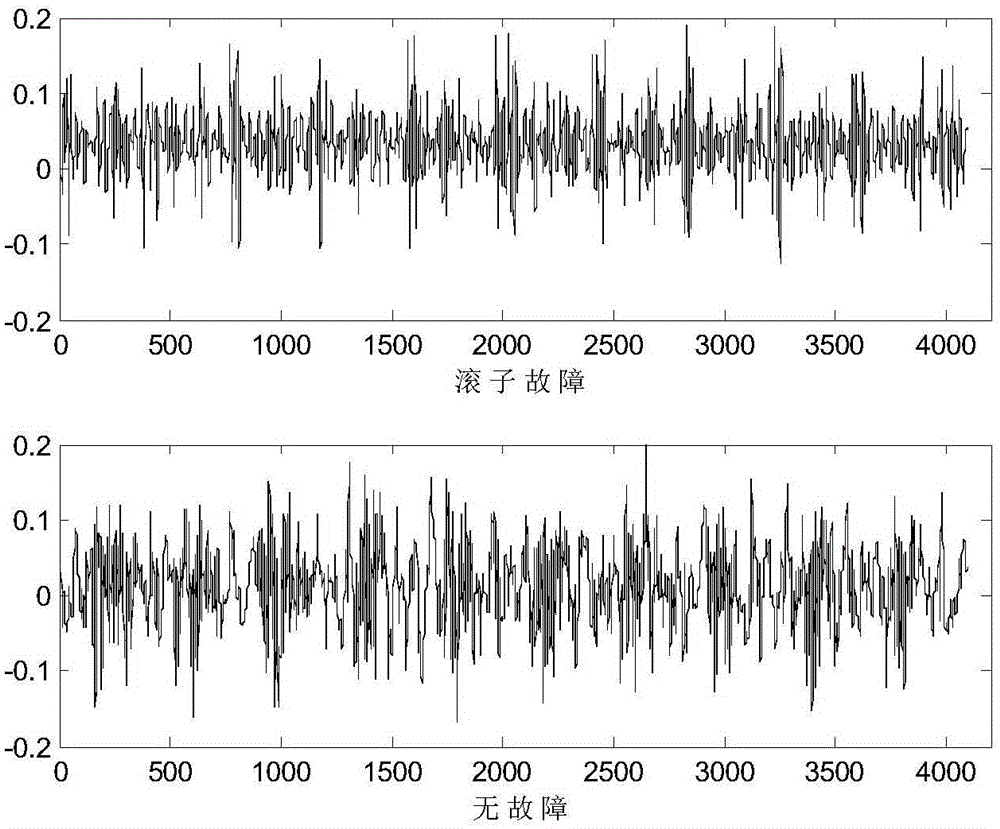

[0072] Firstly, the vibration acceleration signal of the rolling bearing of the train is extracted. In this example, the sampling frequency is 12Khz, and the number of periodic sampling is 4096 times. The signal is filtered using a wavelet filter function. figure 2 Shown are the filtered roller fault and bearing vibration acceleration time-domain signals for normal conditions.

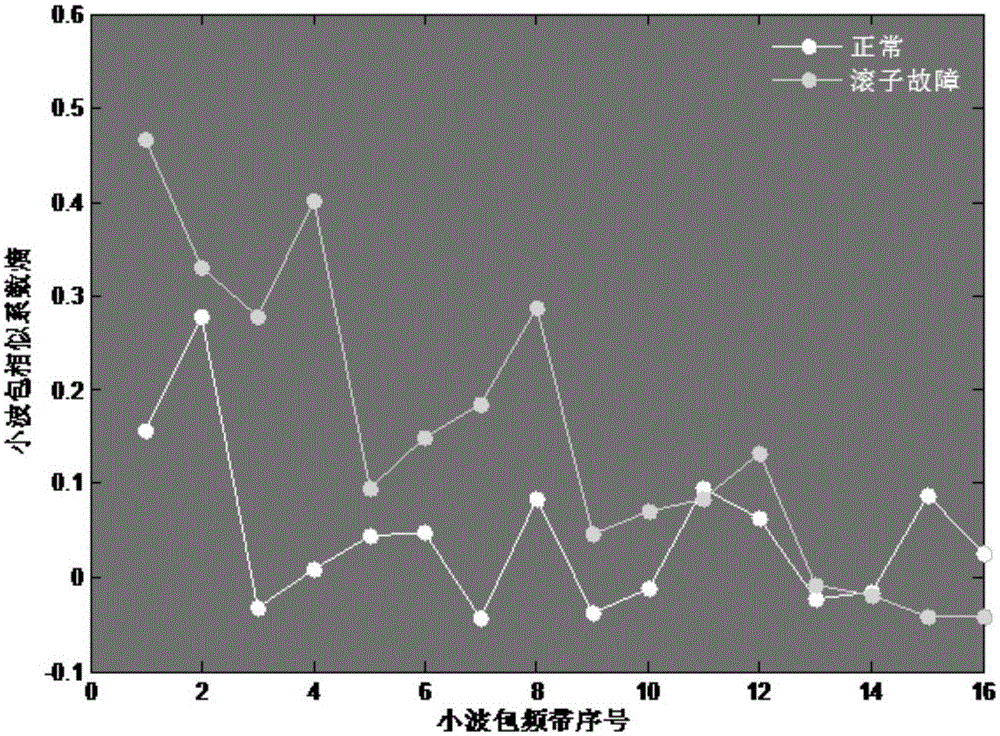

[0073] Then, the wavelet transformation is performed on the vibration acceleration signal of the rolling bearing, and the db3 wavelet base is used to decompose the 4-layer wavelet packet to obtain 16 wavelet packet decomposition coefficients and 16 wavelet subband coefficients. The 16 wavelet subband coefficients extract their correlation coefficient entropy respectively, such as image 3 shown.

[0074] Then all the correlation coefficient entropy is fused with the PCA feature state fuser, and the principal component ratio extracted based on the wavelet packet correlation coefficient entropy is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com