Video-based automatic identification system for abnormal conditions of fused magnesium furnace

A technology for automatic recognition of systems and abnormal working conditions, applied in general control systems, character and pattern recognition, control/regulation systems, etc., can solve problems such as high risk, low accuracy, easy missed detection, false detection, etc., to achieve The effect of high discrimination accuracy, convenient operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

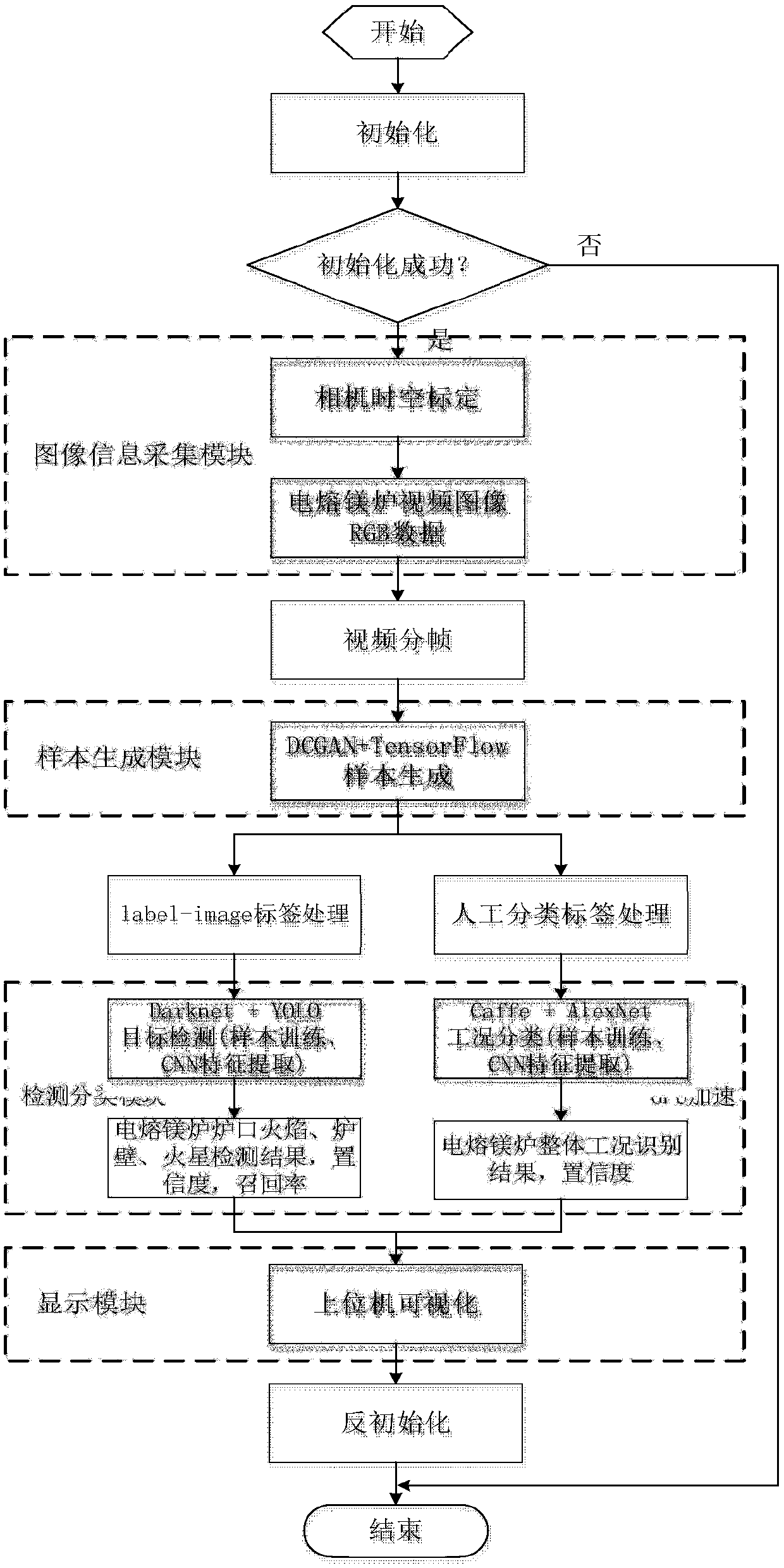

[0042] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

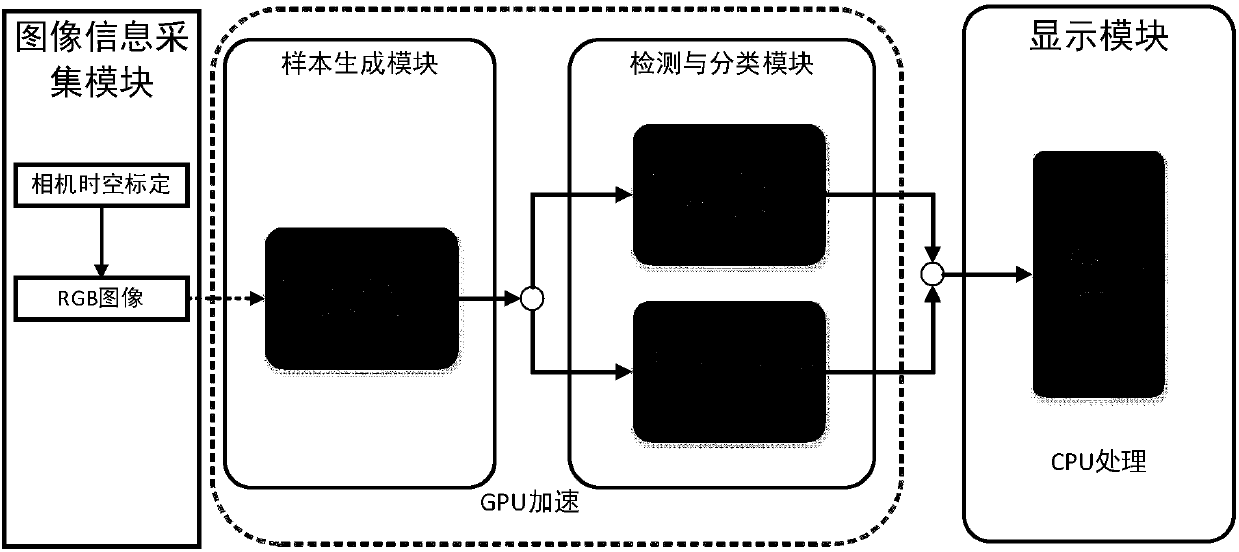

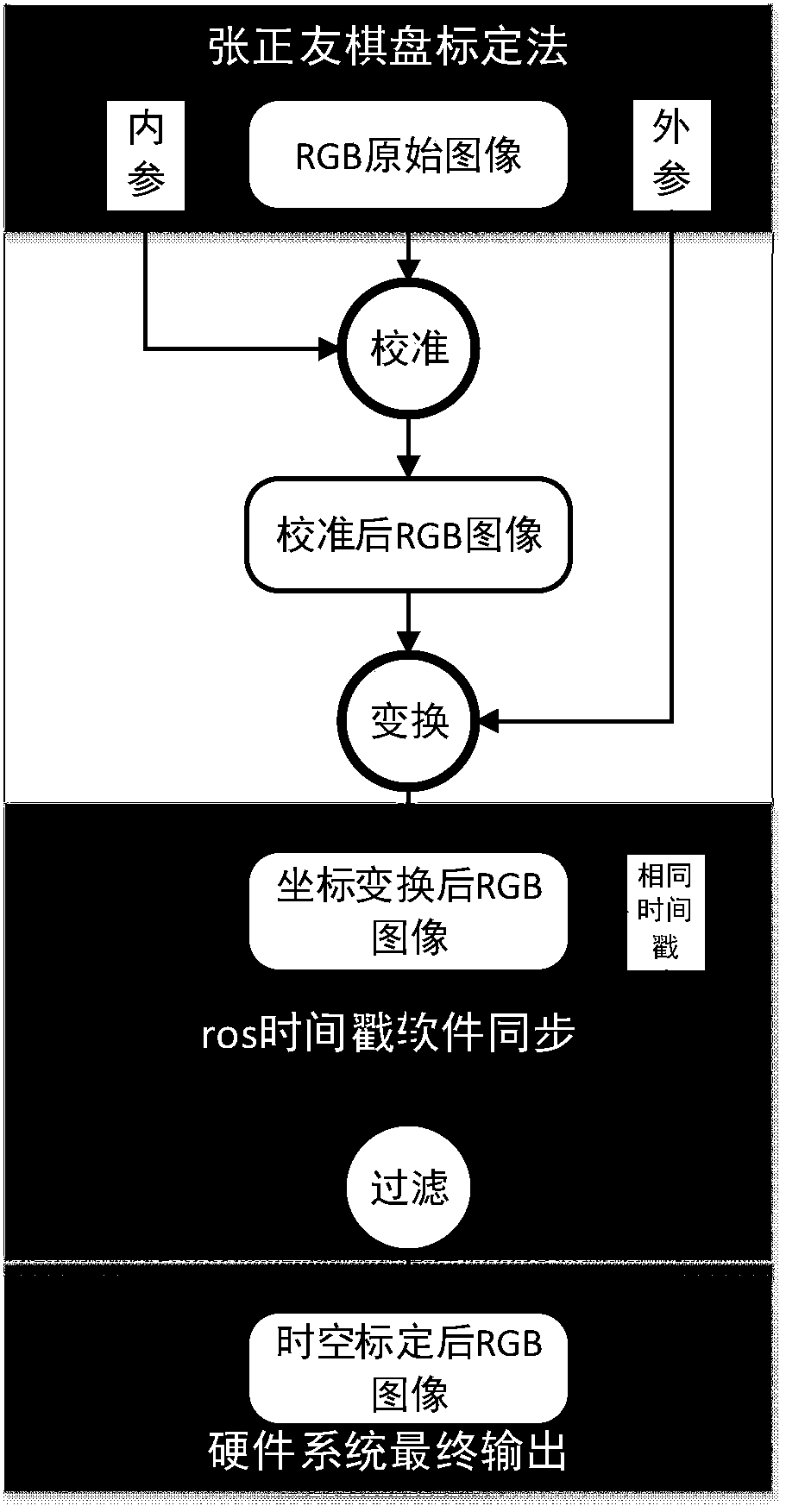

[0043] The invention proposes a video-based automatic identification system for abnormal working conditions of fused magnesia furnaces. This system combines the experience of on-site workers to establish a detection and classification model for video images of abnormal working conditions, and uses industrial cameras to obtain on-site process images of fused magnesia production , through real-time image analysis, online identification of abnormal working conditions is realized. The invention has positive significance for improving the production quality of the fused magnesium, enhancing the degree of visualization and reducing the labor intensity of workers.

[0044] Such as figure 1 As shown, the present invention is a video-based automatic identification system for abnormal working conditions of fused magnesium furnaces, which collects the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com