Slurry conditioning system of zero-wastewater-discharge device and operation method thereof

A zero-emission, conditioning technology, applied in dissolution methods, chemical instruments and methods, mixers with rotary stirring devices, etc., can solve the problems of insufficient dissolution of slaked lime, excessive supply of slaked lime, unstable system operation, etc. Dissolution speed, dissolving promotion, dissolving uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

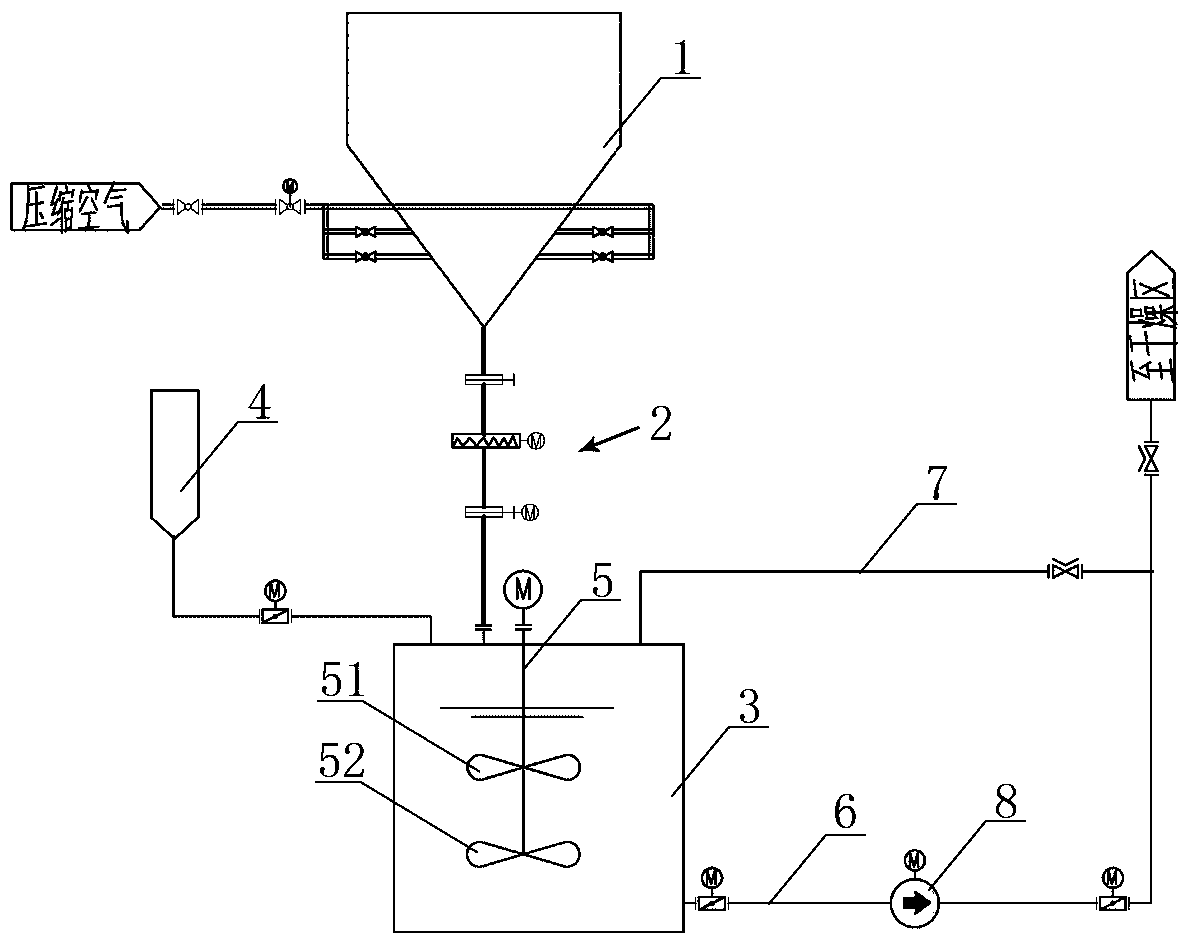

[0036] Examples see figure 1 As shown in the figure, the slurry conditioning system of this waste water zero-discharge device consists of slaked lime powder bin 1, feeding system 2, and conditioning box 3 connected in sequence from top to bottom, and the conditioning box 3 is connected with a thick slurry inlet pipe Road 4, quenched and tempered slurry outlet pipeline 6 and return pipeline 7, a stirrer 5 is arranged in the quenched and tempered tank 3, and a mixing pump 8 is arranged on the quenched and tempered slurry outlet pipeline 6.

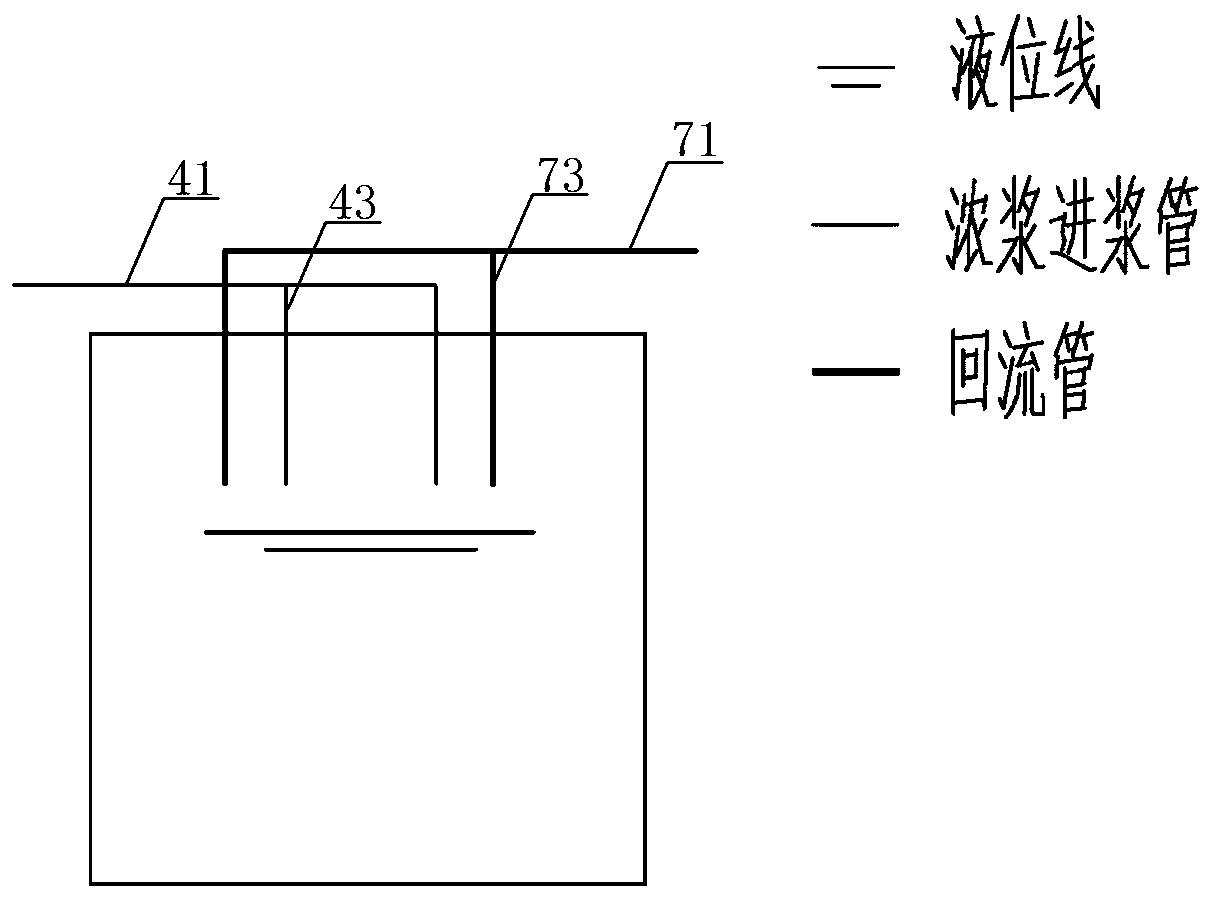

[0037] The thick stock feed pipeline 4 has a main pipe 41, the main pipe is divided into at least two parallel and spaced horizontal sub-pipes 42 above the quenching and tempering box, and a group of vertical sub-pipes are arranged in parallel and spaced on each horizontal sub-pipe 43. The vertical sub-pipe passes vertically downward through the top of the tempering box and communicates with the interior of the tempering box.

[0038] The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com