Main shaft built-in mechanical on-line dynamic balancing system

A mechanical, dynamic unbalanced technology, applied in static/dynamic balance testing, measuring device, machine/structural component testing, etc. Due to the complex structure of the dynamic balancing device and the small space of the spindle process hole, the effects of compact structure, low loss and comprehensive functions are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

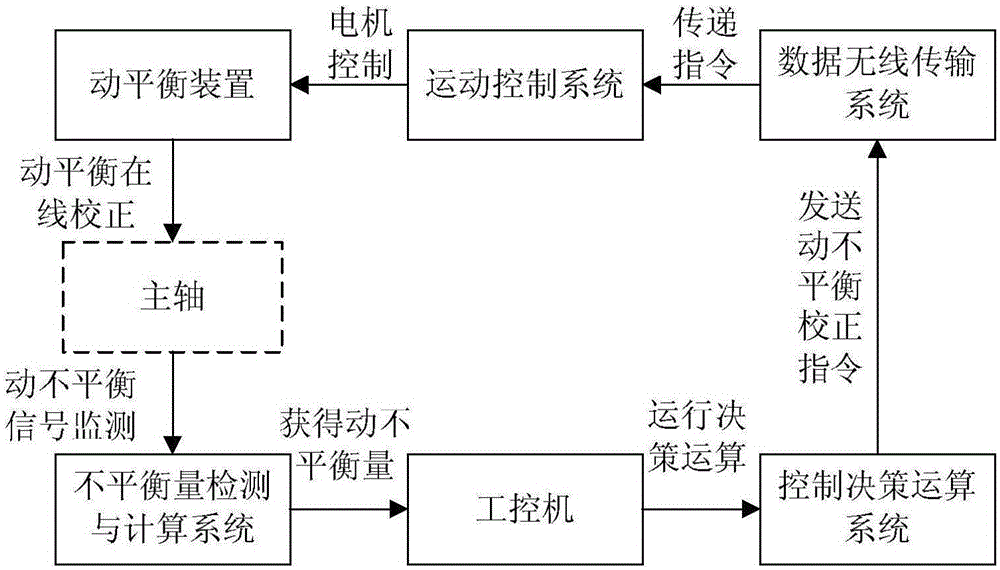

[0063] Example: such as figure 1 Shown, including dynamic balance device, motion control system, data wireless transmission system, dynamic unbalance detection and calculation system, control decision calculation system and industrial computer;

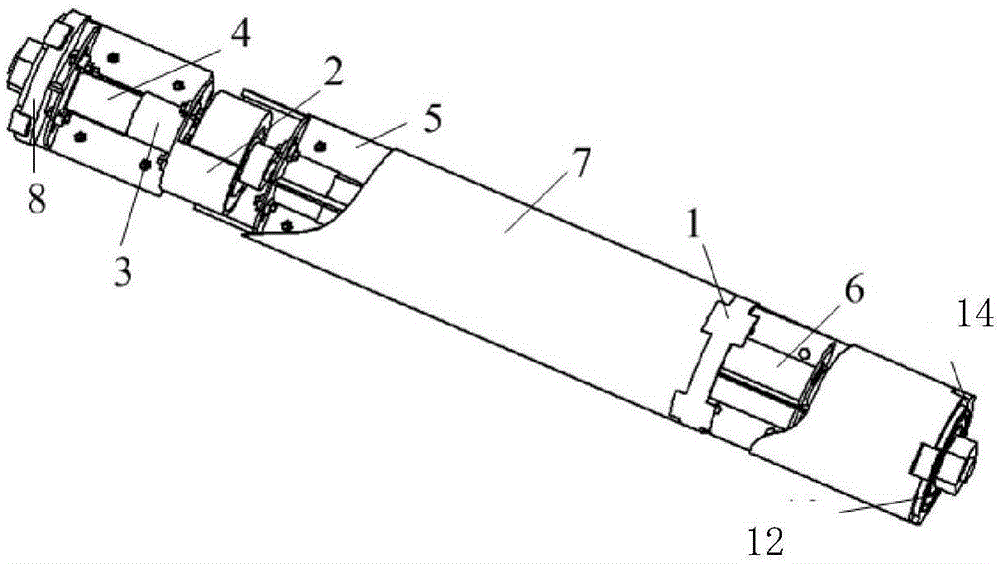

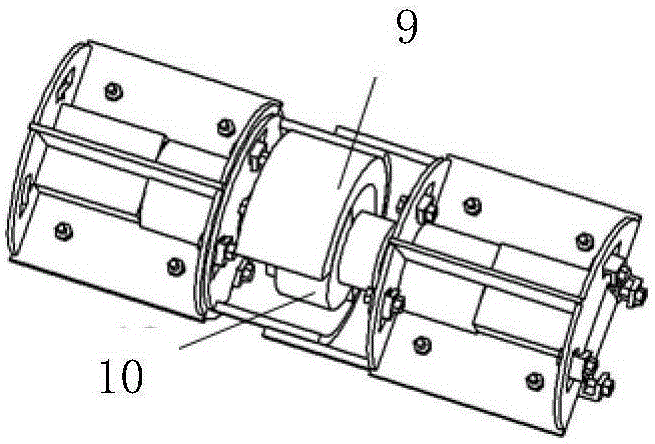

[0064] The dynamic balancing device is placed in the main shaft 19. When working, the mass eccentricity is generated by the two sets of concentric and parallel mass blocks. When the main shaft 19 rotates, the dynamic unbalance force generated by the mass eccentricity is at the same position as that of the main shaft 19 itself. The dynamic balance force of equal magnitude and opposite direction can perform online correction of the dynamic imbalance of the spindle 19;

[0065] The dynamic unbalance detection and calculation system detects the unbalance signal of the spindle, analyzes the characteristics of the spindle dynamic unbalance according to the signal, and calculates the equivalent centrifugal force of the spindle dynamic unbalance an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com