Method used for preparing subsize bismuth subcarbonate via hydrothermal method

A technology of bismuth oxycarbonate and bismuth oxycarbonate wafers, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of different particle sizes, high cost, expensive raw materials, etc., and achieve simple process flow and low cost Low, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

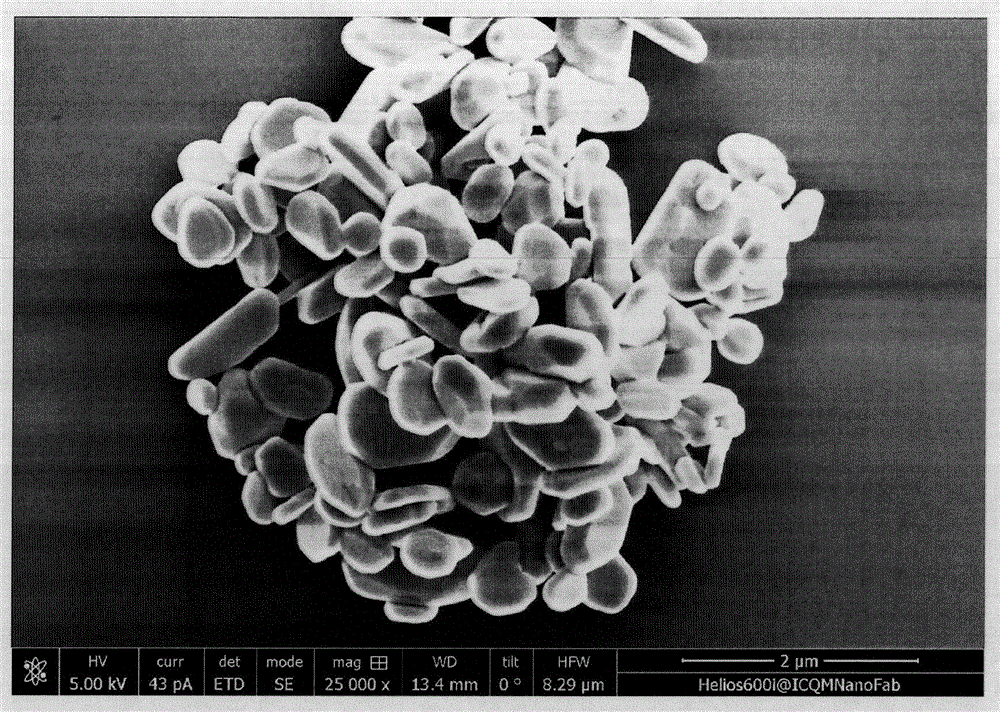

Embodiment 1

[0050] The preparation method of bismuth oxycarbonate nanoscale chip of the present invention, comprises the following steps:

[0051] 1) Add 1mmol and 3mmol into 15ml deionized water at room temperature, stir well to form bismuth oxycarbonate crystal nuclei;

[0052] 2) Transfer the above suspension to a 20mL polytetrafluoroethylene hydrothermal reaction kettle, and react at a constant temperature of 160°C for 18 hours;

[0053] 3) Stop heating and cool down to room temperature naturally;

[0054] 4) Pour off the supernatant of the reaction kettle, and collect the turbid liquid and the precipitation in the lower layer. Add 40mL of deionized water, 1kW ultrasonic oscillation for 5 minutes, then centrifuge at 10,000 rpm for 5 minutes, pour off the supernatant, add ethanol, ultrasonic oscillation for 5 minutes, and continue centrifugation under the same conditions. Repeat the above steps twice to remove impurities;

[0055] 5) drying the cleaned bismuth oxycarbonate wafer in ...

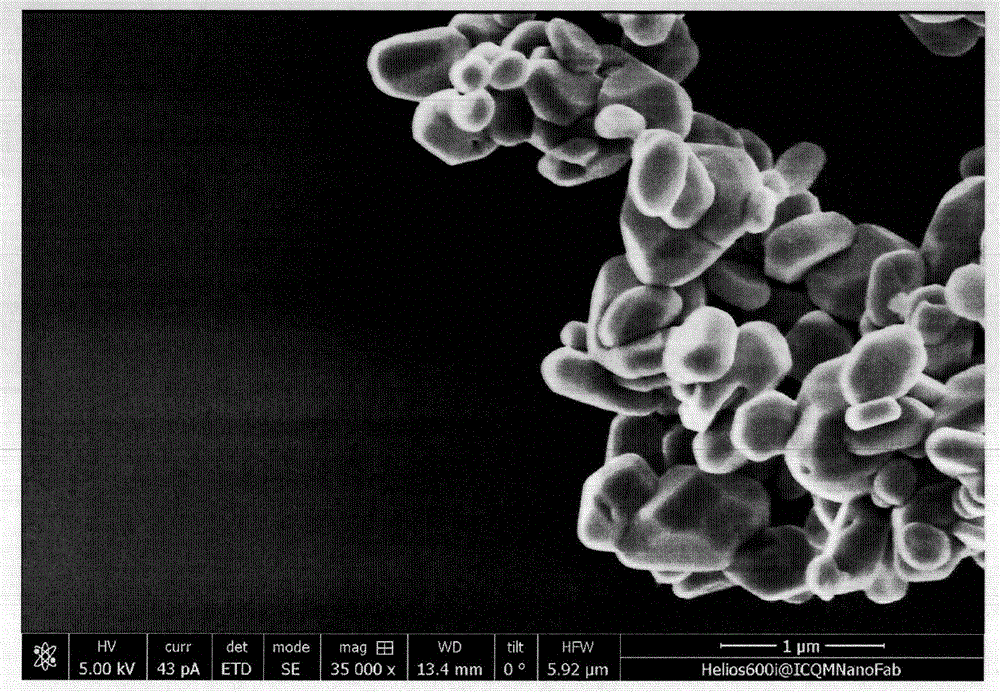

Embodiment 2

[0058] The preparation method of bismuth oxycarbonate nanoscale chip of the present invention, comprises the following steps:

[0059] 1) Add 1mmol and 6mmol into 15ml deionized water at room temperature, stir well to form bismuth oxycarbonate crystal nuclei;

[0060] 2) Add 0.04g of trisodium citrate into the above-mentioned turbid liquid containing bismuth oxycarbonate crystal nuclei, and stir evenly;

[0061] 3) Transfer the above suspension to a 20mL polytetrafluoroethylene hydrothermal reaction kettle, and react at a constant temperature of 160°C for 24 hours;

[0062] 4) Stop heating and cool down to room temperature naturally;

[0063] 5) Pour off the supernatant of the reaction kettle, and collect the turbid liquid and precipitation in the lower layer. Add 40mL of deionized water, 1kW ultrasonic oscillation for 5 minutes, then centrifuge at 10,000 rpm for 5 minutes, pour off the supernatant, add ethanol, ultrasonic oscillation for 5 minutes, and continue centrifugati...

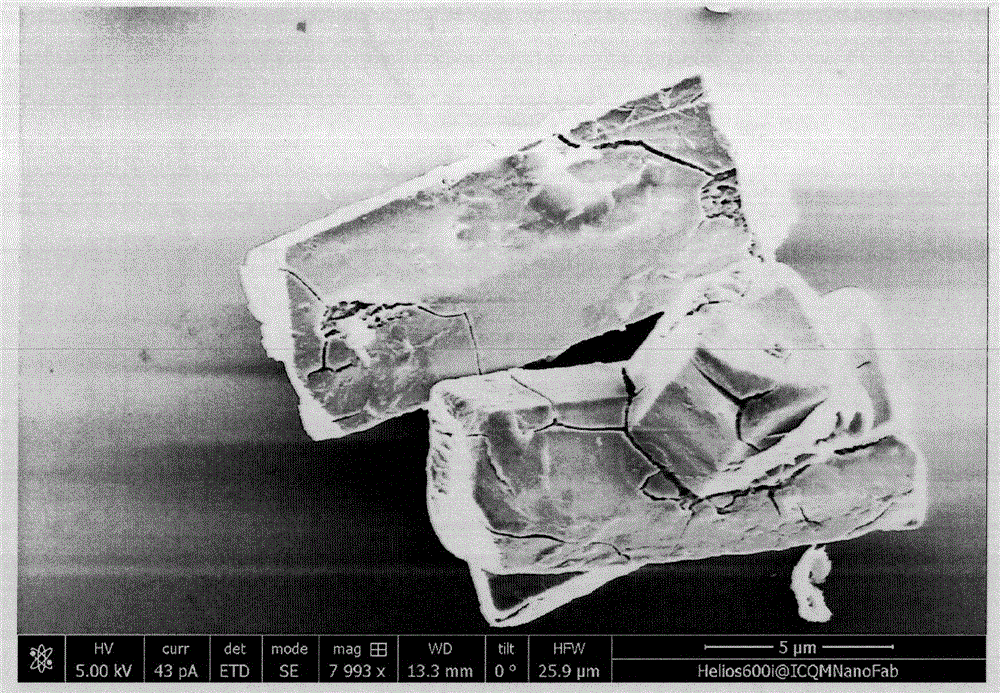

Embodiment 3

[0067] The preparation method of bismuth oxycarbonate micron wafer of the present invention, comprises the following steps:

[0068] 1) Add 0.010mol and 0.035mol into 160ml deionized water at room temperature, and stir thoroughly;

[0069] 2) Transfer the above suspension to a 200mL polytetrafluoroethylene hydrothermal reaction kettle, and react at a constant temperature of 190°C for 36 hours;

[0070] 3) Stop heating and cool down to room temperature naturally;

[0071] 4) Pour off the supernatant of the hydrothermal reaction kettle, filter the turbid liquid and the precipitate in the lower layer, and then wash the precipitate with deionized water and absolute ethanol for 3 times to remove possible impurities;

[0072] 5) drying the cleaned bismuth oxycarbonate wafer in a constant temperature drying oven at 80° C. for 24 hours to obtain a powdery high-purity nano-scale bismuth oxycarbonate wafer.

[0073] The test results show that the purity of the generated bismuth oxycar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com