A low-resistivity solvent-free epoxy carbon-based electrostatic conductive coating

An epoxy-carbon conductive and low-resistivity technology, applied in conductive coatings, epoxy resin coatings, coatings, etc., to achieve excellent mechanical damage resistance, easy construction, good bonding force and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

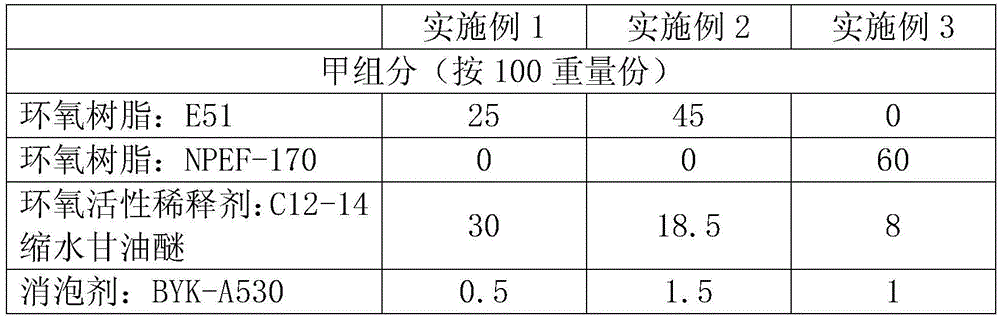

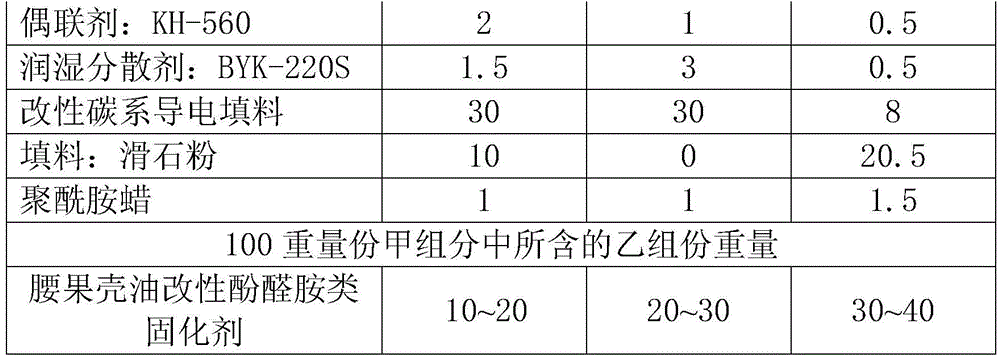

Examples

Embodiment Construction

[0033] The present invention is a solvent-free epoxy carbon-based electrostatic conductive coating with low resistivity. The key point of the present invention is the preparation of modified carbon-based conductive fillers. The coating film formed by curing the solvent epoxy carbon-based electrostatic conductive coating has excellent electrostatic conductivity, which meets the needs of various industries for electrostatic conductive coatings.

[0034] The low-resistivity solvent-free epoxy carbon-based static conductive coating of the present invention is composed of component A and component B, wherein component A contains epoxy resin, epoxy reactive diluent, defoamer, coupling agent, Wetting and dispersing agent, modified carbon-based conductive filler, filler and polyamide wax, component B is cashew nut shell oil modified phenalkamine curing agent. Epoxy resin is either E51 or NPEF-170. It is required that the molecular weight of E51 or NPEF-170 is between 200 and 500, the ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com