A kind of preparation method of linear low density polyethylene

A linear low density, polyethylene technology, applied in the field of preparation of linear low density polyethylene, can solve the problems of poor copolymerization ability of active centers, uneven composition distribution of copolymerization products, etc., and achieves easy production process, low production cost, and insertion amount. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the pre-activated catalyst is: under the condition of anhydrous and oxygen-free, about 1g of supported TiCl 4 / MgCl 2 Add the catalyst into a 50ml Schlenk bottle, add 30ml of n-heptane refluxed with a potassium-sodium alloy, add the corresponding alkylaluminum according to the designed aluminum-titanium ratio, and stir and react at 20-50°C for 10-120min. After standing for precipitation, separate the supernatant, then add 20ml of n-heptane that has been refluxed with a potassium-sodium alloy to wash the catalyst, stir for 1-5min, set aside for precipitation, and separate the supernatant. Finally, the solvent was drained, and the obtained catalyst was transferred to a glove box for future use.

[0020] The specific conditions of the polymerization reaction include: the concentration of Ti in the polymerization system (calculated according to the ratio of the number of moles of Ti in the main catalyst added to the amount of solvent used) is 2×10...

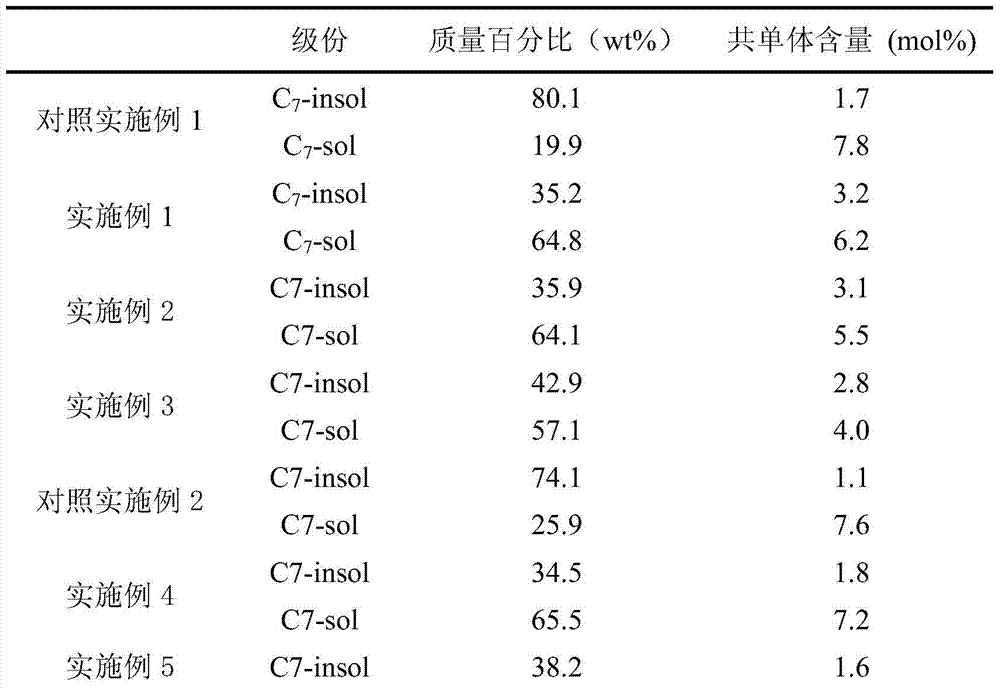

Embodiment 1

[0024] Preactivation of supported TiCl with trimethylaluminum 4 / MgCl 2 Catalyst, the amount of trimethylaluminum is added according to Al / Ti=1, obtains the pre-activated loaded TiCl 4 / MgCl 2 Catalyst (Catalyst 1). With 17mg of catalyst 1 as the main catalyst, triisobutylaluminum (Al / Ti=100) as the cocatalyst, and 100mL of n-heptane as the solvent, add 5% (volume fraction) H 2 , the concentration of 1-hexene is 0.4mol / L, and the slurry polymerization of ethylene and 1-hexene is catalyzed at 50°C and 0.4MPa to obtain 10.4g copolymerized product, and the molar content of 1-hexene in the product is 5.1%.

Embodiment 2

[0026] Preactivation of supported TiCl with triethylaluminum 4 / MgCl 2 Catalyst, the amount of triethylaluminum is added according to Al / Ti=2, obtains the pre-activated loaded TiCl 4 / MgCl 2 Catalyst (Catalyst 2). With 17mg of catalyst 2 as the main catalyst, triisobutylaluminum (Al / Ti=100) as the cocatalyst, 100mL of n-heptane as the solvent, adding 10% (volume fraction) H 2 , the concentration of 1-octene is 0.4mol / L, catalyzed the slurry polymerization of ethylene and 1-octene at 50°C and 0.4MPa to obtain 11.7g copolymerization product, the molar content of 1-octene in the product is 4.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com