Iron-containing aluminum chloride solution iron removal method

A technology of aluminum chloride and solution, applied in the field of chemical separation, can solve the problems of high cost and low efficiency, and achieve the effects of low cost, high iron removal rate, and no additional pollution to the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

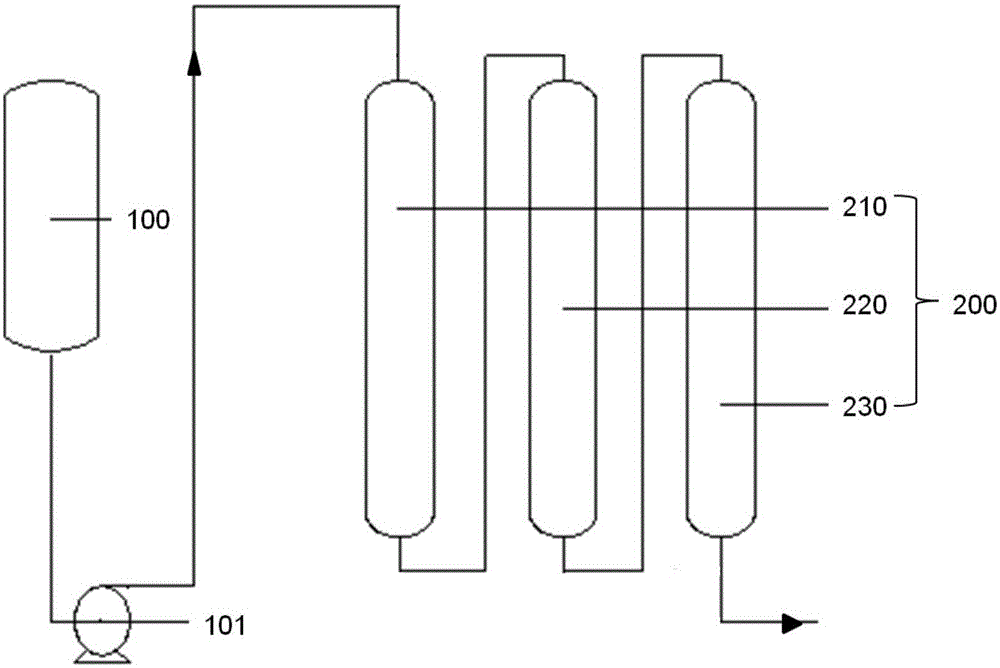

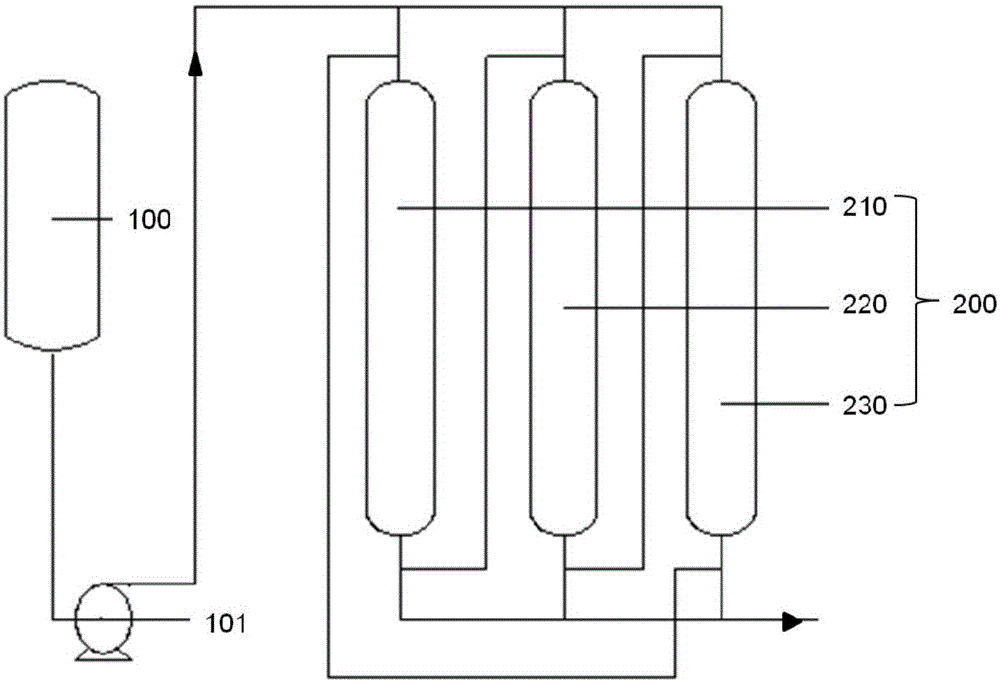

Image

Examples

Embodiment 1 to 8

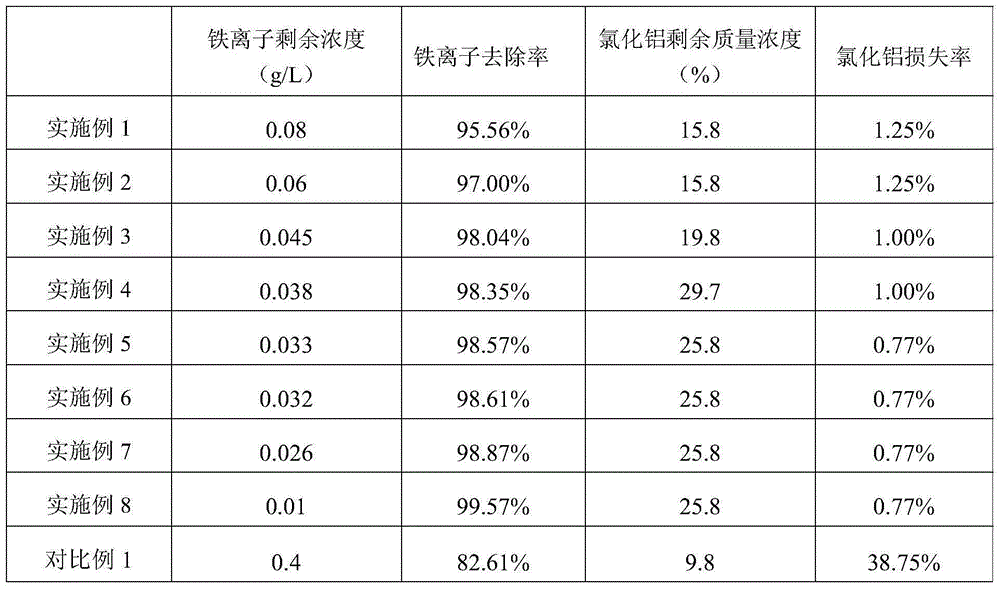

[0037] Embodiment 1 to 8 is the iron removal experiment of iron-containing aluminum chloride:

Embodiment 1

[0039] Take an iron-containing aluminum chloride solution with an aluminum chloride mass percentage of 16% and an iron ion concentration of 1.8 g / L. After controlling its temperature at 15°C, the solution was passed through a single resin column containing 201×7 anion exchange resin at a flow rate of 5BV / h through a corrosion-resistant pump. And the way of passing the solution through the column is from top to bottom.

Embodiment 2

[0041] Take an iron-containing aluminum chloride solution with a mass percentage of aluminum chloride of 16% and an iron ion concentration of 2 g / L. After controlling its temperature at room temperature, the solution was passed through a single resin column containing 201×7 anion exchange resin at a flow rate of 4 BV / h through a corrosion-resistant pump. And the way of passing the solution through the column is from top to bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com