Method for preparing submicron all-silicon DD3R molecular sieve

A molecular sieve and sub-micron technology, applied in the chemical industry, can solve the problems of long synthesis time, cumbersome process and high cost, and achieve the effect of shortening the synthesis period, uniform crystal size and increasing the crystallization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, 0.046wt% seed crystals are added, the molar ratio of water to silicon in the silicon source is 100, and all-silicon DD3R molecular sieves are synthesized by microwave at 160° C. for 12 hours.

[0040] After mixing 1.68 g of tetraethylammonium hydroxide with 1.51 g of amantadine, add 33.1 g of H 2 O stirred for about 0.5 hour, then slowly added dropwise 3 gram of silica sol, SiO in the silica sol 2 The content of DD3R was 40wt%. After stirring for 24 hours, 20 mg of all-silicon DD3R seed crystals were added, stirred for 5 minutes, and then heated by microwave at 160° C. for 12 hours. After the product is taken out, it is washed with deionized water, centrifuged, and dried to obtain all-silicon DD3R molecular sieve crystals.

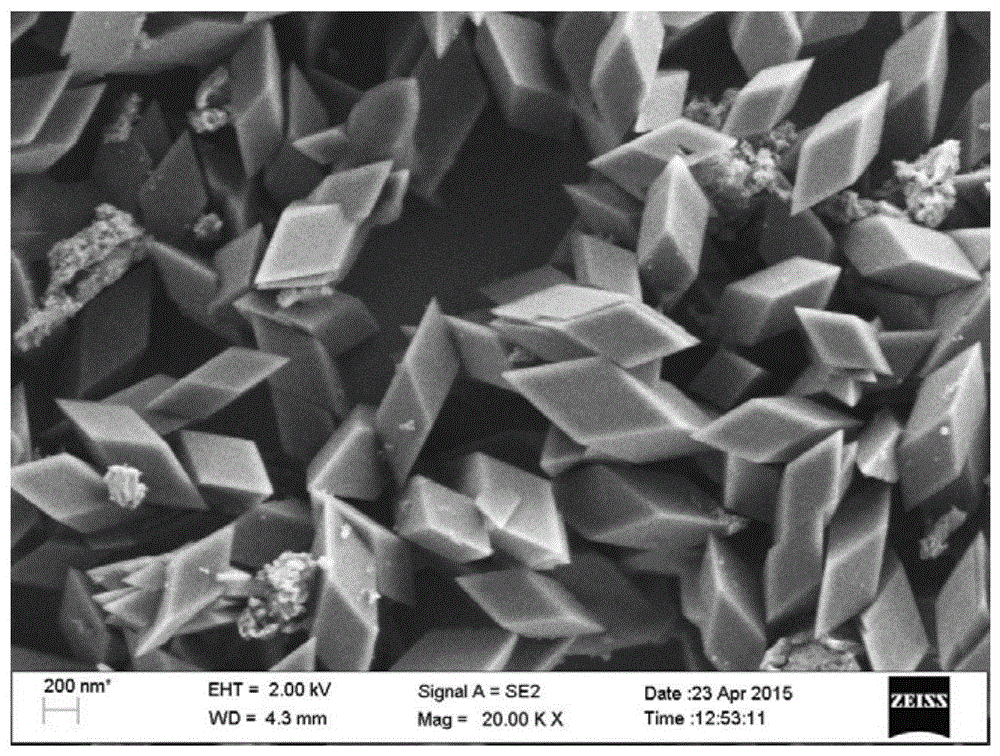

[0041] figure 1 It is a scanning electron microscope photograph of the all-silicon DD3R molecular sieve crystal in this example, the all-silicon DD3R molecular sieve crystal is a rhombohedral crystal of about 1 micron, the crys...

Embodiment 2

[0044] In this example, 0.046wt% seed crystals were added, the molar ratio of water to silicon in the silicon source was 50, and the all-silicon DD3R molecular sieve was synthesized by microwave at 160° C. for 12 hours.

[0045] The difference from Example 1 is that the molar ratio of water to silicon in the silicon source is 50, and the rest of the steps and parameters are the same as in Example 1.

[0046] image 3 This is the scanning electron microscope photo of the all-silicon DD3R molecular sieve crystal obtained in this example. The all-silicon DD3R molecular sieve crystal is a rhombohedral crystal of about 0.7 microns, the crystal size is relatively uniform, and the yield is >80%.

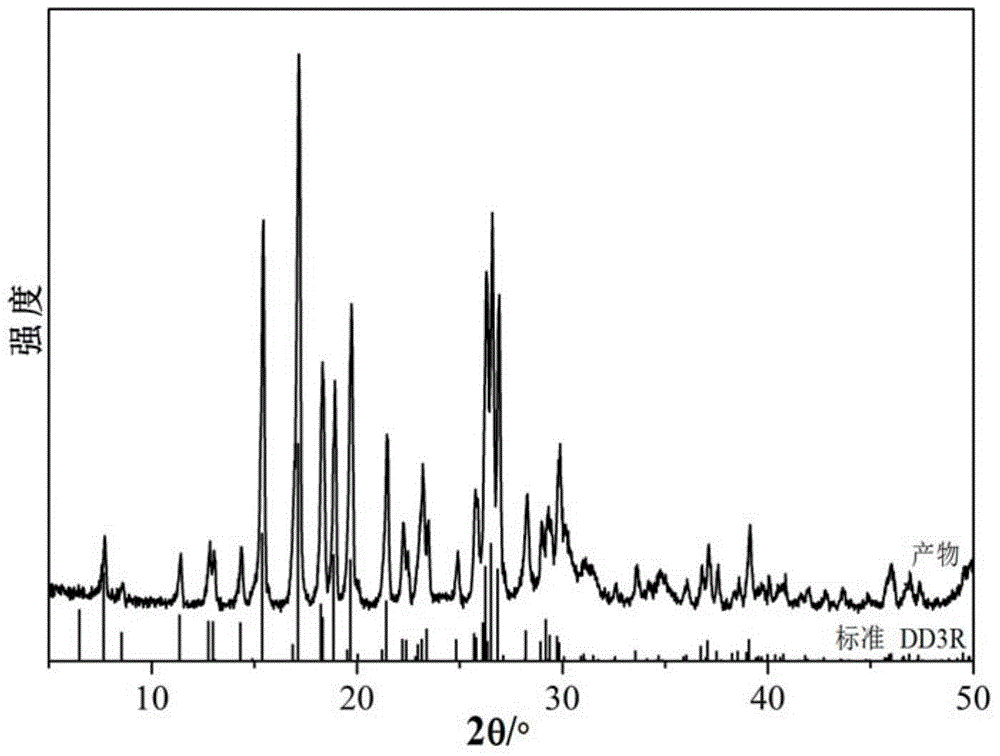

[0047] Figure 4 It is the XRD spectrum of the all-silicon DD3R molecular sieve crystal obtained in this example, which is consistent with the standard spectrum.

Embodiment 3

[0049] In this example, 0.046wt% seed crystals were added, the molar ratio of water to silicon in the silicon source was 30, and the all-silicon DD3R molecular sieve was synthesized by microwave heating at 160° C. for 12 hours.

[0050] The difference from Example 1 is that the molar ratio of water to silicon in the silicon source is 30, and the rest of the steps and parameters are the same as in Example 1.

[0051] Figure 5 It is a scanning electron microscope photo of an all-silicon DD3R molecular sieve crystal. The all-silicon DD3R molecular sieve crystal is a rhombohedral crystal of about 0.4 microns, the crystal size is relatively uniform, and the yield is >80%. At the same time, the specific surface area measured by nitrogen adsorption is 256m 2 / g.

[0052] Figure 6 It is the XRD spectrum of the all-silicon DD3R molecular sieve crystal, which is consistent with the standard spectrum.

[0053] Figure 7 It is the nitrogen adsorption isotherm of the all-silicon DD3R m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com