Stir-fry-type activated charcoal stove

An activated carbon and activated carbon technology, applied in the field of activated carbon production equipment, can solve the problems of increased activated carbon cost, high equipment corrosion, application limitations, etc., to achieve the effects of unique equipment, fast construction, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

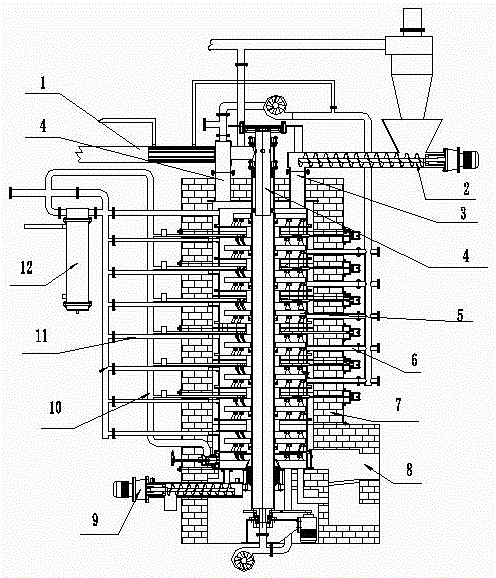

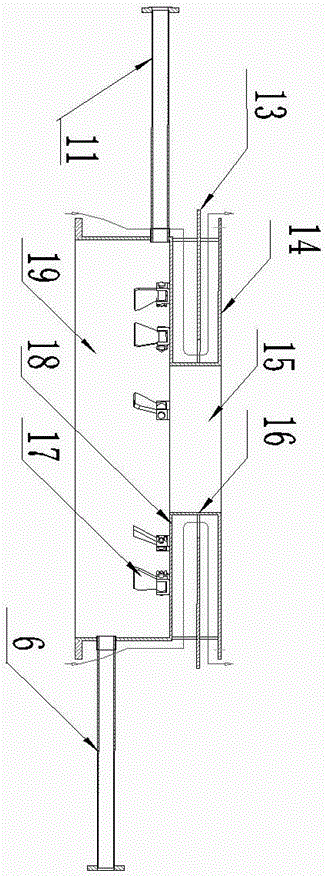

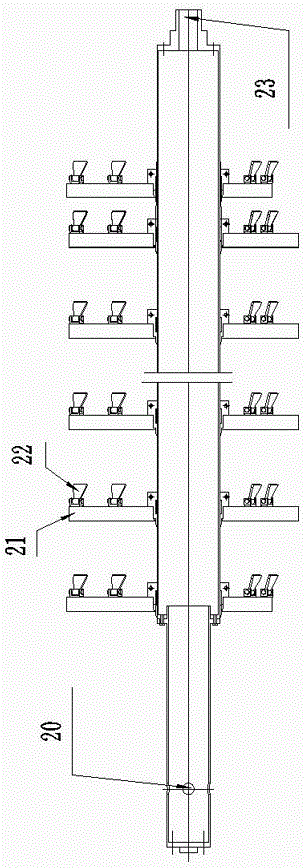

[0020] A frying-type activated carbon furnace is provided with a furnace body, the furnace body is provided with a heat-insulating shell 7, a hearth is arranged in the heat-insulating shell 7, and the upper part of the furnace body is provided with a feed pipe 3, a smoke exhaust pipe 4, and a smoke exhaust pipe 4 Connected to the flue gas main pipe 1, the lower part of the furnace body is provided with an activated carbon discharge port, and the furnace body from the feed port to the discharge port is equipped with a vertical furnace hearth, and a number of fixed furnaces are arranged in the furnace hearth The hearth 5 is formed by vertically superimposing the sections. The center of the hearth 5 is provided with a rotating mandrel 4, and a combustion pyrotechnic channel is provided between the hearth and the inner wall of the heat preservation shell. Room 19, the lower part of the material frying and mixing chamber 19 is an open structure, the top of the material frying and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com