Floor surface board and its manufacturing method

A manufacturing method and surface plate technology, applied in manufacturing tools, chemical instruments and methods, building structures, etc., can solve problems such as poor surface wear resistance and burning resistance, and achieve enhanced wear resistance, enhanced performance, and quality. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the drawings and embodiments.

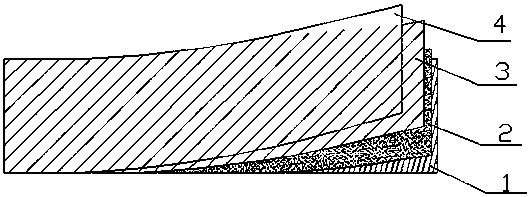

[0022] Reference figure 1 The floor surface board of the present invention is composed of a substrate, a coating layer on the surface of the substrate, a decorative layer and a wear-resistant layer in sequence.

[0023] The manufacturing method includes the following steps:

[0024] 1) Substrate: use 3~4mm fast-growing veneer;

[0025] 2) Substrate coating layer: Coat the surface of the substrate with melamine resin adhesive, the amount of melamine resin adhesive is 10g / m 2 ~40g / m 2 , And dry at 60~80℃, and the drying time is 5~8 minutes;

[0026] 3) Decorative layer: Use non-woven fabric or paper and 0.2~0.4mm sliced veneer to be compounded, impregnated with melamine resin adhesive, dipping amount is 70%~90%, volatile content is 8%~15%, pre-curing degree 40%~70%;

[0027] 4) Wear-resistant layer: The wear-resistant layer is made of aluminum oxide wear-resistant paper impreg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com