A centering clamping device

A technology of clamping device and centering shaft, applied in the direction of clamping device, positioning device, clamping, etc., can solve the problems of poor centering effect, etc., and achieve the effect of high precision and good centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

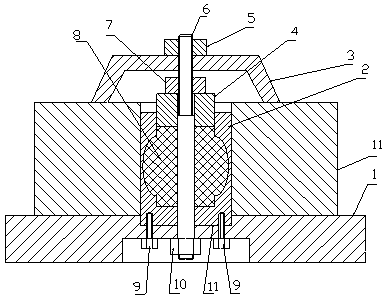

[0010] combined with figure 1 , the specific embodiment of the present invention is:

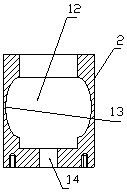

[0011] A centering clamping device according to the present invention includes a base (1). The base (1) is not only the basis for the installation and positioning of the device, but also a bridge connecting the entire device with machine tools or other equipment. , on the base (1), it is necessary to reserve an installation position connected to the machine tool and connecting devices such as bolt holes, and a centering shaft (2) is installed on the base (1), and the centering shaft (2 ) is shaped on a large hole (12) in the middle of the large hole (12), and a section of annular waist hole (13) with a diameter greater than the diameter of the large hole (12) is made at the waist position of the large hole (12). The mandrel (2) has a thinner wall thickness, and a small through hole (14) is formed at the bottom of the large hole (12). The centering shaft (2) is fixed on the base (1) by bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com