Concentric chamfering device

A chamfering device and chamfering technology, which are applied in the field of chamfering equipment, can solve the problem that long hole chamfering is difficult to ensure concentricity, etc., and achieve the effect of strong applicability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

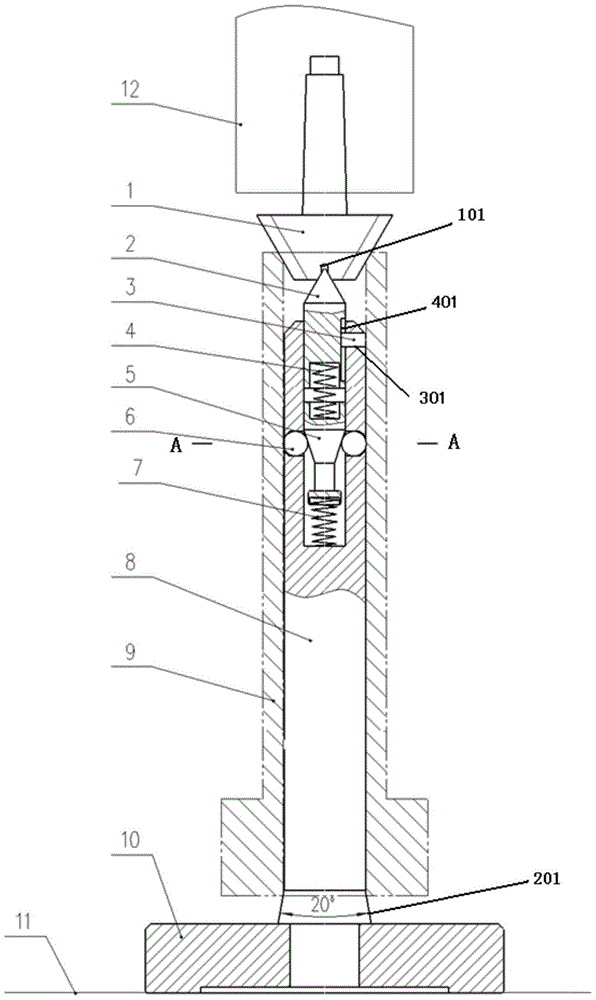

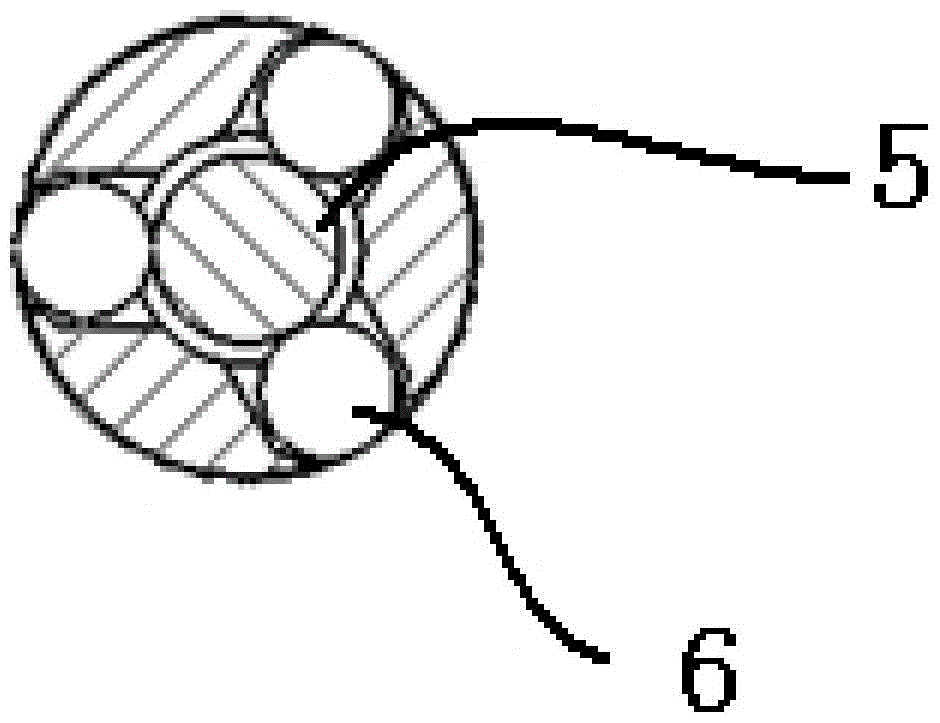

[0027] see Figure 1-2 shown. in figure 1 is the sectional view of the concentric chamfering device; figure 2 for figure 1 Middle A-A sectional view.

[0028] The device is a chamfering tool designed by skillfully using the self-centering principle of the cone, which greatly reduces the processing cost, and its principle is scalable.

[0029] The device is placed on a table 11. The device includes a base 10 for a fixing device; a chamfering countersink 1 is used for turning workpieces, and the chamfering countersinking 1 is arranged on the machine tool spindle 12; The center hole 101 of the corner spot facing drill 1 and the floating top 2 realize the positioning and concentricity of the tool and the device; The inner cavity (not shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com