A method for preparing silver nanowires by microwave alcohol reduction

A technology of silver nanowire and microwave, which is applied in the field of preparation of silver nanowire, can solve the problem that the transparent conductive film is difficult to achieve haze, and achieve the effects of small diameter, good repeatability and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Take 0.3g of silver nitrate, 100mL of propylene glycol, and 3mg of cetyltrimethylammonium bromide, mix them uniformly, and then perform microwave treatment under 100w microwave conditions for 2 minutes to obtain the precursor mixture A.

[0035] (2) Take 300 mL of alcohol reducing agent propylene glycol, 1.5 g of protective agent povidone, 3 mg of surfactant tetrabutylammonium chloride, and 3 mg of inorganic salt ferric nitrate, and stir and mix them evenly to obtain mother liquor B.

[0036] (3) Keep the mother liquid B at 120°C and keep it stable. Use a metering pump to accurately measure and inject the precursor mixed liquid A into the mother liquid B at a rate of 1% of the total volume of the precursor mixed liquid A into the mother liquid B per minute. In the process, the solution was reacted to grayish yellow to stop the reaction, and silver nanowires were obtained.

[0037] figure 1 It is a scanning electron microscope picture of the silver nanowires prepare...

Embodiment 2

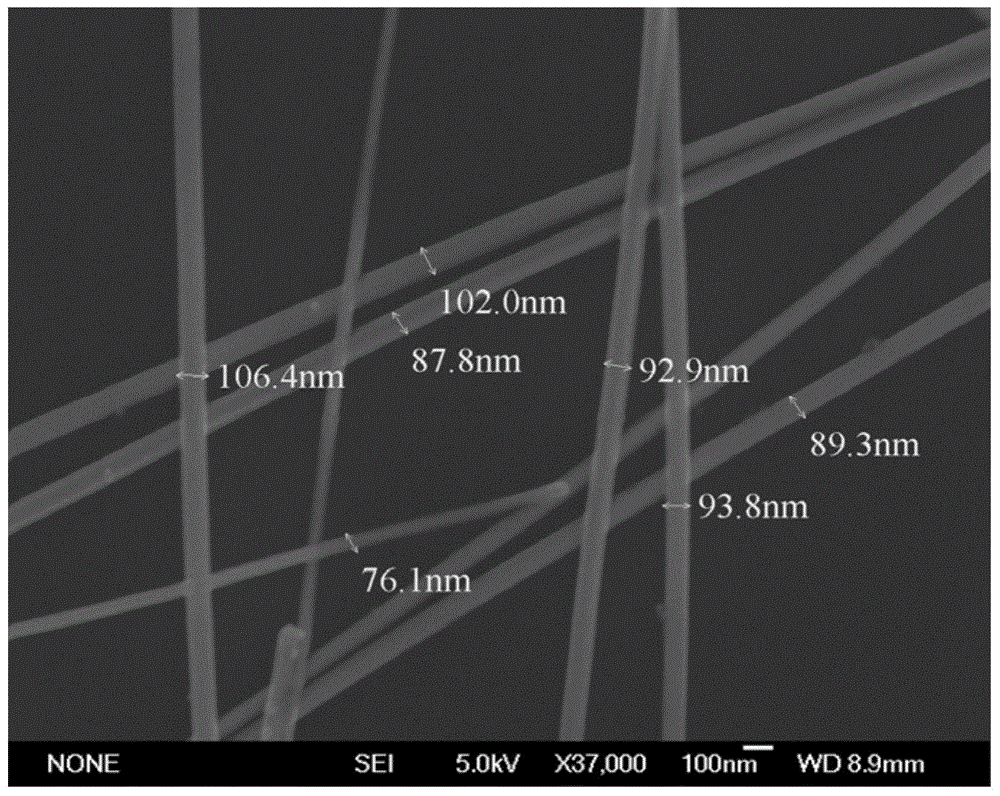

[0039] In this example, silver nanowires were prepared in the same manner as in Example 1, except that microwave treatment was not performed in step (1). image 3 It is a scanning electron microscope picture of the silver nanowires prepared in this example. It can be seen that the silver nanowires obtained in this example have a diameter of 76-106 nm.

Embodiment 3

[0041] (1) Take 0.3g of silver nitrate, 100mL of glycerol, and 9mg of tetrabutylammonium chloride, mix them uniformly, and then perform microwave treatment under 100w microwave conditions for 2 minutes to obtain the precursor mixed solution A.

[0042] (2) Take 300 mL of alcohol reducing agent propylene glycol, 1.5 g of protective agent povidone, 9 mg of surfactant tetrabutylammonium chloride, and 9 mg of inorganic salt ferric nitrate, and stir and mix them evenly to obtain mother liquor B.

[0043] (3) Keep the mother liquid B at 120°C and keep it stable. Use a metering pump to accurately measure and inject the precursor mixed liquid A into the mother liquid B at a rate of 1% of the total volume of the precursor mixed liquid A into the mother liquid B per minute. In the process, the solution was reacted to grayish yellow to stop the reaction, and silver nanowires were obtained. Figure 4 It is a scanning electron microscope image of the silver nanowires prepared in this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com