Automatic H-shaped piston pushing ring arranging device

A lining ring, automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low work efficiency and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

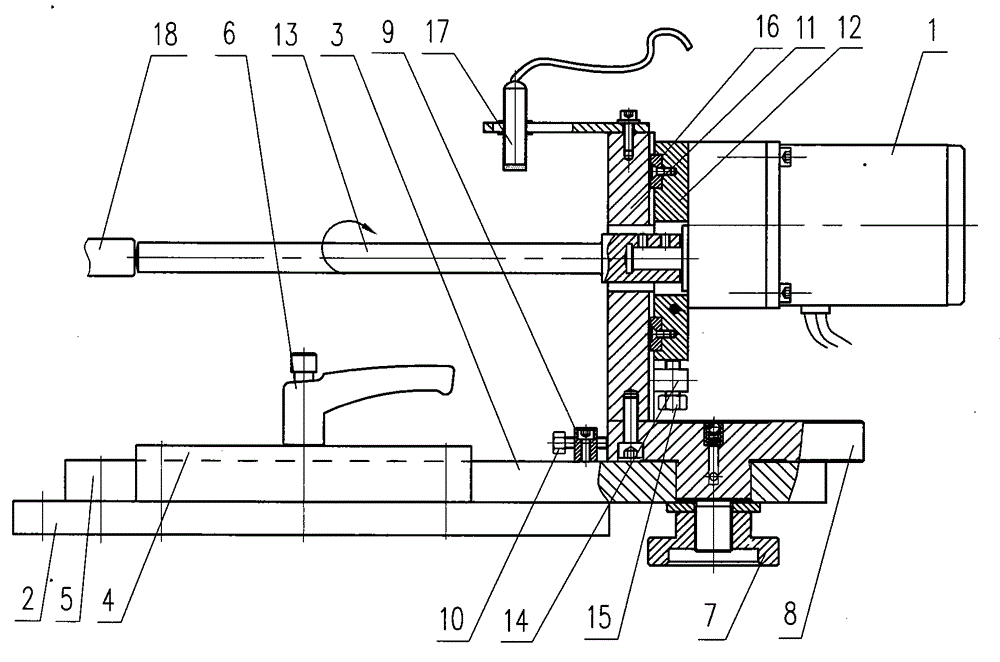

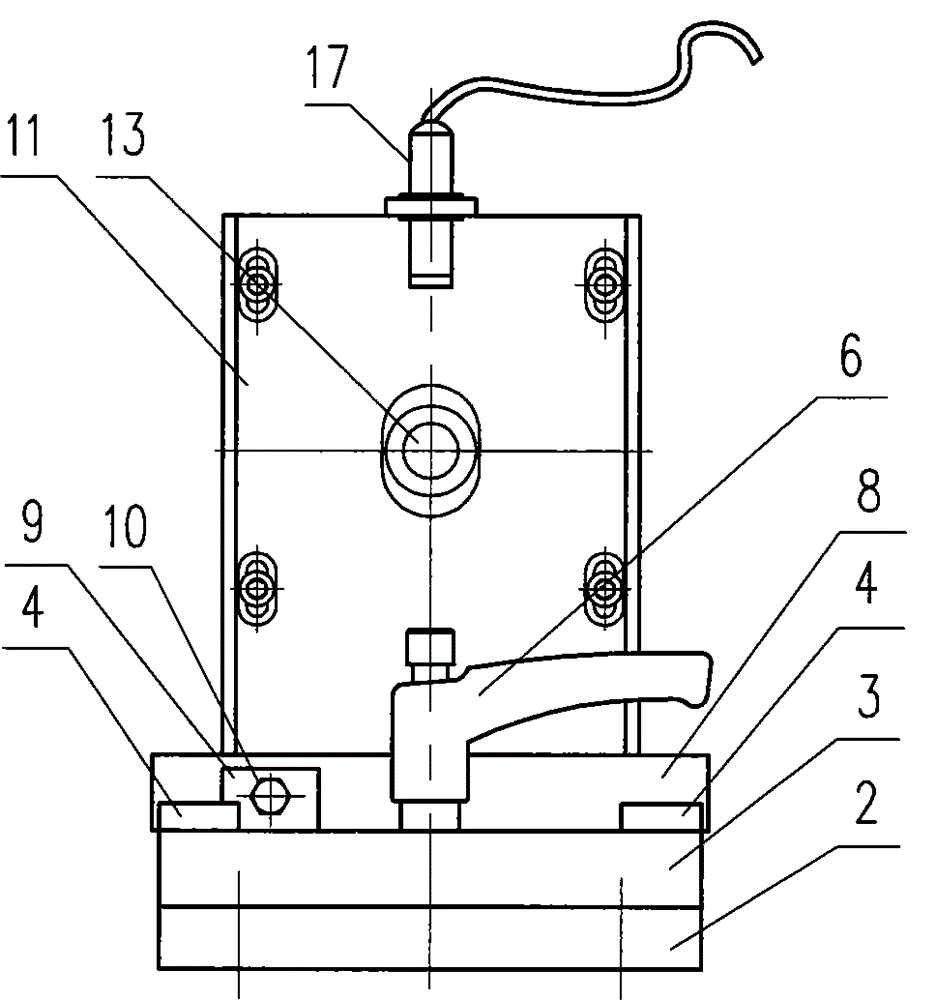

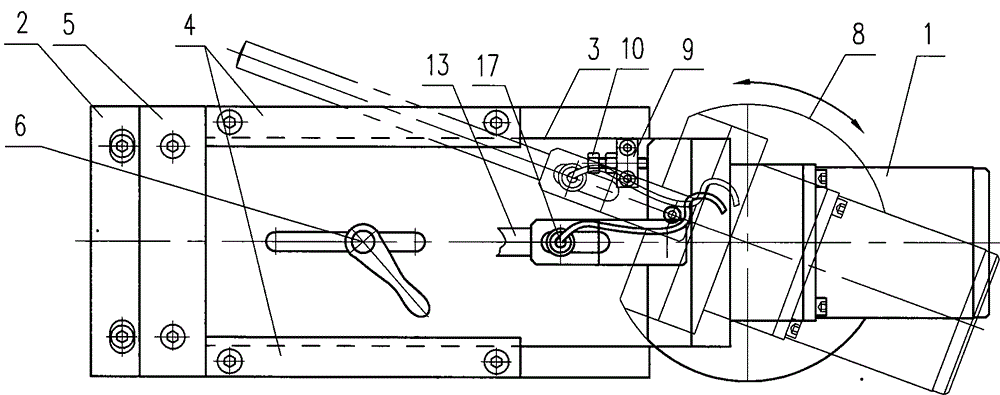

[0009] A kind of H-type piston liner automatic ring arrangement device of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] Depend on figure 1 , figure 2 , image 3 It can be seen that in the present embodiment, a kind of H-type piston lining automatic ring arrangement device is composed of frequency conversion reduction motor 1, bottom plate 2, slider 3, slider pressure plate 4, front baffle plate 5, brake handle 6, knurled hand wheel 7 , turntable 8, turntable adjustment block 9, turntable adjustment screw 10, motor adjustment plate 11, motor fixed plate 12, guide ring rod 13, motor adjustment block 14, motor adjustment screw 15, guide key 16 and signal sensor 17 form. Both the slider 3 and the slider pressing plate 4 are installed on the base plate 2, by image 3 It can be seen that in this embodiment, the slider pressing plate 4 has two front and rear pieces, which play a position-limiting role on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com