A highly preferentially oriented anatase-type tio 2 Nanotube array film and its preparation method

A nanotube array and preferred orientation technology, which is applied in the field of anatase TiO2 nanotube array film and its preparation, can solve the problems of reducing photocatalytic or photoelectrochemical performance, and achieve low photogenerated electron-hole recombination probability and high photocatalysis , the effect of high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Anatase-type TiO with highly preferred orientation in this example 2 Nanotube array film, its preparation process is:

[0018] (1) Cold-rolling high-purity titanium foil (Ti purity 99.5%) to obtain titanium foil with surface texture

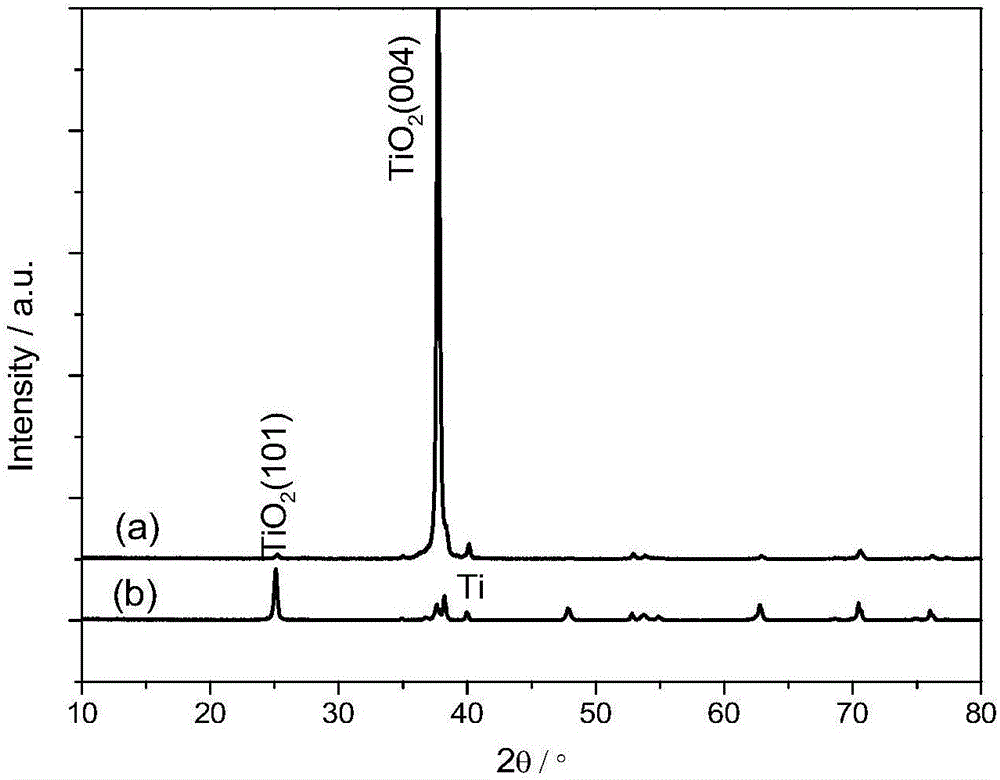

[0019] figure 1 The X-ray diffraction patterns of the raw material high-purity titanium foil in the annealed state (a) and cold-rolled state (b), it can be seen from the figure that the relative intensities of the diffraction peaks of the annealed titanium foil are consistent with the standard spectrum (44-1294). , the (002) diffraction peak of the cold-rolled titanium foil is enhanced, indicating that the preferential orientation of Ti grains appears on the surface.

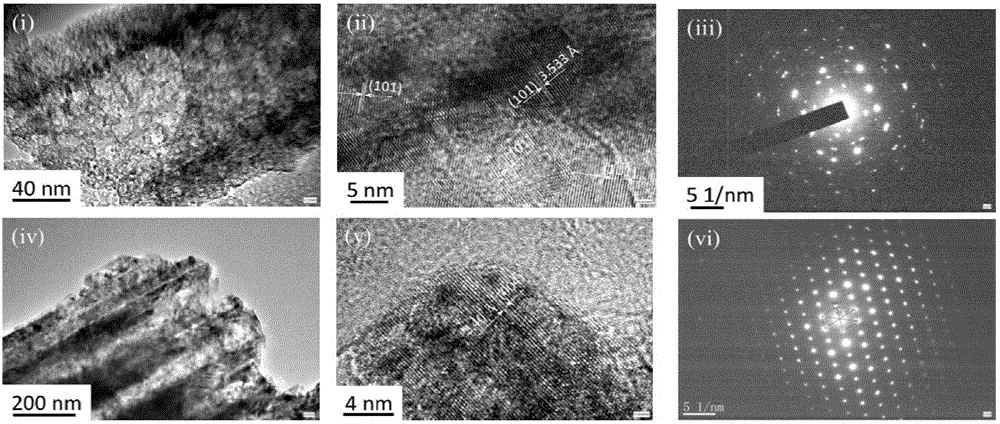

[0020] (2) After thoroughly cleaning the surface of the titanium foil with surface texture, perform anodization treatment to form TiO on the surface of the titanium foil substrate 2 Nanotube array membrane, the electrolyte used is ethylene glycol solution containing 0.3mo...

Embodiment 2

[0028] The preparation method of this example is the same as that of Example 1, except that the calcination and crystallization time in step (3) is changed to 5h.

[0029] TiO prepared in this example 2 The nanotube array film has a (004) crystal plane preferential orientation, which is tested at 36mW / cm 2 The photocurrent density was 337.6 μA / cm under UV light irradiation 2 , which is about the same as that of ordinary TiO 2 2.6 times the photocurrent density of NTAs.

Embodiment 3

[0031] The preparation method of this example is the same as that of Example 1, except that the calcination and crystallization time in step (3) is changed to 7h.

[0032] TiO prepared in this example 2 The nanotube array film has a (004) crystal plane preferential orientation, which is tested at 36mW / cm 2 Under the irradiation of ultraviolet light, the photocurrent density was 370 μA / cm 2 , which is about the same as that of ordinary TiO 2 2.9 times the photocurrent density of NTAs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com