Transformer deteriorated oil adsorbent and preparation method thereof

A degraded oil and adsorbent technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as inability to handle and utilize, produce acid residue and alkali residue, and hidden dangers to operator safety, and achieve better adsorption effect Good, low cost, and the effect of improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

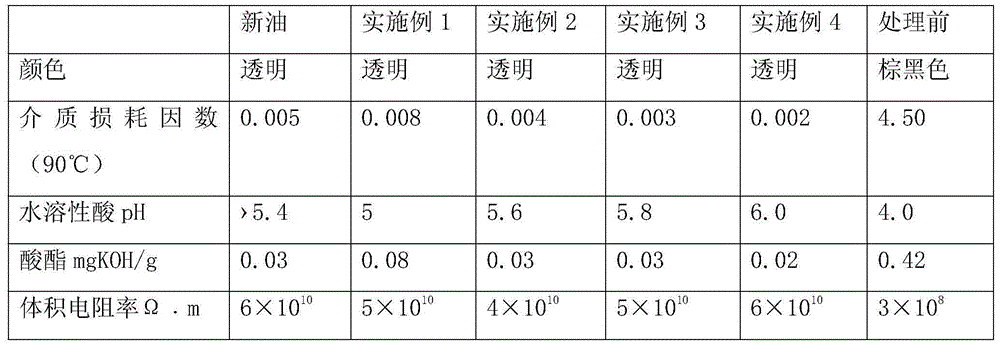

Examples

Embodiment 1

[0020] An adsorbent for degraded transformer oil comprises the following effective components in parts by weight: 30 parts of aluminum oxide, 40 parts of sodium silicate and 30 parts of aluminum chloride.

[0021] The raw material alumina powder, sodium silicate powder and aluminum chloride powder plus mass fraction of 40% sulfuric acid are mixed evenly, and the mixture obtained in (1) is made into particles with a particle diameter of 2 mm by a molding machine; then the particles are placed Bake in an oven at 70°C for 2 hours; then quickly raise the temperature to 700°C, and dry for 1 hour to obtain the finished product of adsorbent particles 3, the specific surface area of the prepared particles is 256m 2 / g.

[0022] When in use, put the finished product of the adsorbent particle 3 in the transformer oil to absorb it by natural sedimentation, and keep the temperature of the transformer oil at a relatively high temperature, such as 60°C, during the adsorption.

Embodiment 2

[0024] This embodiment is the same as Embodiment 1 except the following features:

[0025] An adsorbent for degraded transformer oil comprises the following effective components in parts by weight: 40 parts of aluminum oxide, 30 parts of sodium silicate and 25 parts of aluminum chloride. Alumina, sodium silicate, aluminum chloride plus mass fraction are 25% sulfuric acid and are mixed evenly, and the mixture obtained in (1) is made into particles with a particle diameter of 3 mm by a molding machine; then the particles are placed in an oven at 70 Bake at ℃ for 2 hours; then quickly raise the temperature to 700℃, and dry for 1 hour to get the finished product of adsorbent particles 3, the specific surface area of the prepared particles is 262m 2 / g.

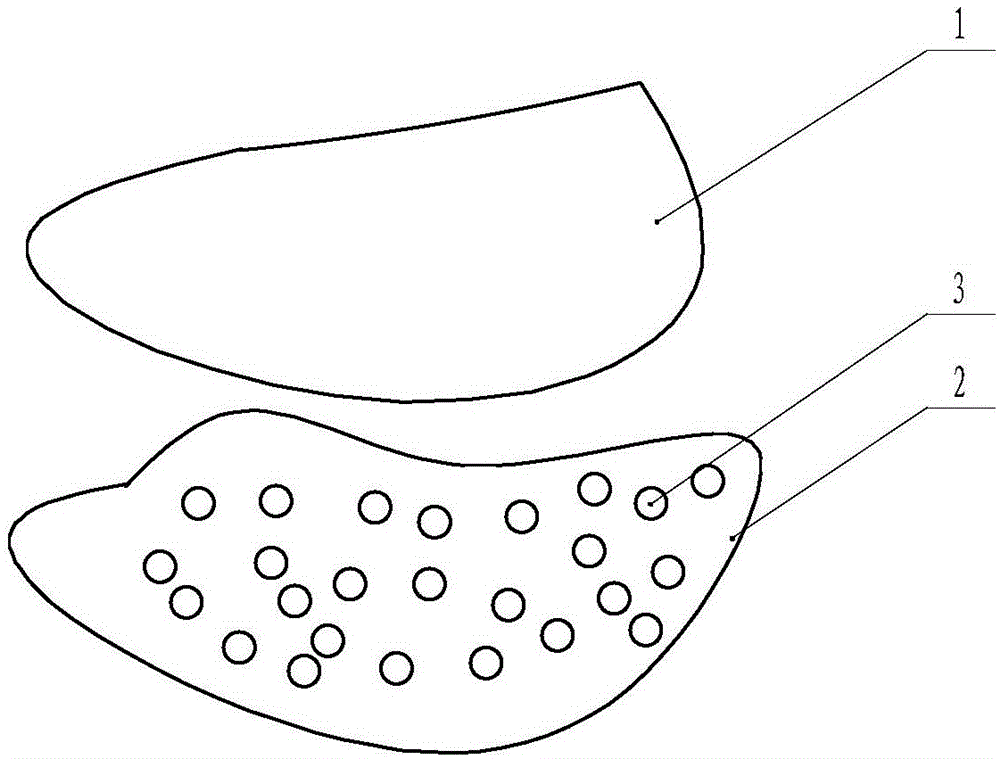

[0026] After the finished product of adsorbent particles 3 is obtained, the adsorption filter plate is made according to the following method: the adsorption filter plate includes filter plate I1 placed on the upper layer and f...

Embodiment 3

[0028] This embodiment is the same as Embodiment 2 except the following features:

[0029] An adsorbent for degraded transformer oil comprises the following effective components in parts by weight: 35 parts of aluminum oxide, 35 parts of sodium silicate and 25 parts of aluminum chloride. Alumina, sodium silicate, aluminum chloride plus mass fraction are 30% sulfuric acid and mix uniformly, and the mixture obtained in (1) is made into particles with a particle diameter of 3 mm by a molding machine; then the particles are placed in an oven at 70 Bake at ℃ for 2 hours; then quickly raise the temperature to 700℃, and dry for 1 hour to get the finished product of adsorbent particles 3, the specific surface area of the prepared particles is 252m 2 / g.

[0030] The finished adsorbent particle 3 is placed above the filter plate I1, and filter paper or filter cloth is placed above the finished adsorbent particle 3. The filter plate I1 has a pore size of 250 um, and the filter plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com