Raschig ring filling material

A Raschig ring filler, terephthalate epoxy resin technology, applied in chemical/physical/physical chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of reducing specific surface area and porosity, Problems such as low internal surface wetting rate, liquid channel flow and wall flow, etc., achieve the effect of increasing void ratio, long service life, and preventing channel flow and wall flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

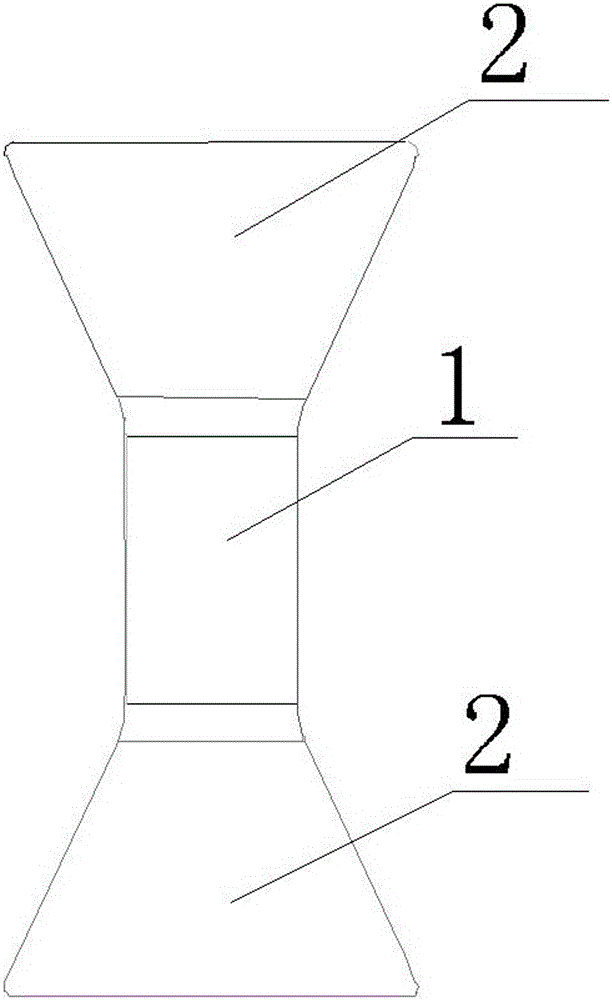

[0014] The Raschig ring packing of this embodiment includes a tubular body 1 , and two ends of the tubular body 1 are provided with symmetrical horn-shaped flares 2 , and the diameter of the outermost end of the horn-shaped flares 2 is twice the diameter of the tubular body 1 . The flared flare is half the length of the tubular body. The surface of the Raschig ring filler is sprayed with a corrosion-resistant coating, and the corrosion-resistant coating includes the following components in terms of weight percentage: 10%-20% terephthalate epoxy resin, 10%-15% polyvinyl formal , 11%-15% of cross-linking agent, 6%-8% of anhydrous additive, 2%-3% of catalyst, and the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com