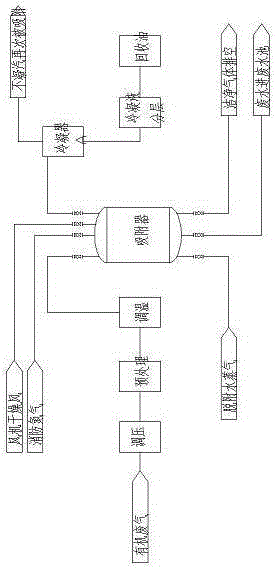

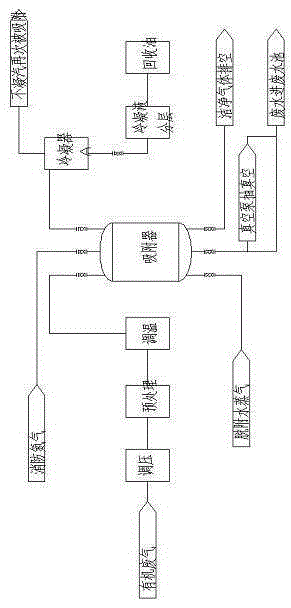

Vacuum drying active carbon waste gas management process and vacuum drying active carbon waste gas management apparatus

A technology for vacuum drying and exhaust gas treatment, which is applied in steam condensation, petroleum industry, and combustible gas purification. Save treatment costs, shorten drying time, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

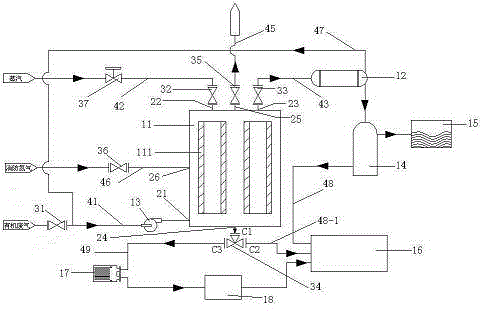

Image

Examples

Embodiment 1

[0029]A vacuum-dried activated carbon waste gas treatment process based on the above-mentioned device is characterized in that it includes a pretreatment stage, an adsorption stage, a desorption and recovery stage, and a drying stage. The pretreatment stage is: taking into account the absorber's capacity and process needs , before the organic waste gas enters the adsorber, it is necessary to adjust the pressure, pretreatment and temperature adjustment of the organic waste gas. When the organic waste gas is first discharged, it is a high-pressure gas or a low-pressure gas. The valve is throttled and discharged, and enters the buffer tank for buffering and decompression until it reaches 9kpa. The organic waste gas after the pressure adjustment still contains more solid particles, which need to be filtered through a filter to filter out the solid particles, and then pass through the heat exchanger To adjust the temperature, in order to improve the absorbability of organic waste ga...

Embodiment 2

[0035] A vacuum-dried activated carbon waste gas treatment process based on the above-mentioned device is characterized in that it includes a pretreatment stage, an adsorption stage, a desorption and recovery stage, and a drying stage. The pretreatment stage is: taking into account the absorber's capacity and process needs , before the organic waste gas enters the adsorber, it is necessary to adjust the pressure, pretreatment and temperature adjustment of the organic waste gas. When the organic waste gas is first discharged, it is a high-pressure gas or a low-pressure gas. The valve is throttled and discharged, and enters the buffer tank for buffering and decompression until it reaches 8kpa. The organic waste gas after the pressure adjustment still contains more solid particles, which need to be filtered through a filter to filter out the solid particles, and then pass through the heat exchanger To adjust the temperature, in order to improve the absorbability of organic waste g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com