Application of calcium poly-malate in the preparation of feed acidifier

A feed acidifier, calcium malate technology, applied in application, animal feed, animal feed, etc., can solve the problems of inability to inhibit the growth of harmful microorganisms, inability to effectively reduce the pH value of the small intestine, and increase the production cost of acidifiers, achieving significant Anti-stress effect, improve disease resistance, improve pH and microenvironment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The method for preparing calcium polymalate, comprises the steps:

[0021] (1) Strain seed culture: Aureobasidium pullulans (Aureobasidium pullulans) with the preservation number of CCTCC NO: M 2012223 was inoculated in a shake flask containing 50 mL of seed medium (the volume of the shake flask was 500 mL), and the temperature was 25 ° C. , cultivated for 48 hours under the condition of 220 rpm;

[0022] (2) Polymalic acid fermentation: take the culture solution of step (1) and inoculate it in a 300L fermenter containing 220L fermentation medium according to the inoculum size of 10%, and then inoculate it at a temperature of 25°C and an aeration ratio of 1:1 (v / v) or above, and the residual sugar concentration is above 20g / L, ferment for 144 hours, and add CaCO during the fermentation process 3 Solution control pH is 6.0; Detect polycalcium malate output after fermentation, the result shows that the output of present embodiment polycalcium malate is 156g / L;

[0023]...

Embodiment 2

[0027] The method for preparing calcium polymalate, comprises the steps:

[0028] (1) Strain seed culture: Aureobasidium pullulans (Aureobasidium pullulans) with the preservation number of CCTCC NO: M 2012223 was inoculated in a shake flask containing 50 mL of seed medium (the volume of the shake flask was 500 mL), and the temperature was 25 ° C. , cultivated for 48 hours under the condition of 220 rpm;

[0029] (2) polymalic acid fermentation: the culture solution of step (1) is inoculated in a 300L fermenter containing 220L fermentation medium by 10% of the inoculum size, and then the temperature is 25°C and the aeration ratio is 1:1.2 (v / v) or above, and the residual sugar concentration is above 20g / L, ferment for 150 hours, and add CaCO during the fermentation process 3 Solution control pH is 5.5; Detect polycalcium malate output after fermentation, the result shows that the output of present embodiment polycalcium malate is 167g / L;

[0030] (3) extract calcium polymala...

Embodiment 3

[0037] Effect of feeding piglets with polycalcium malate compound additive

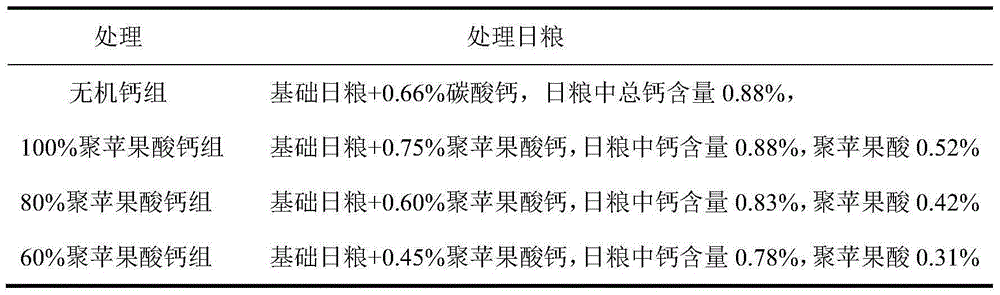

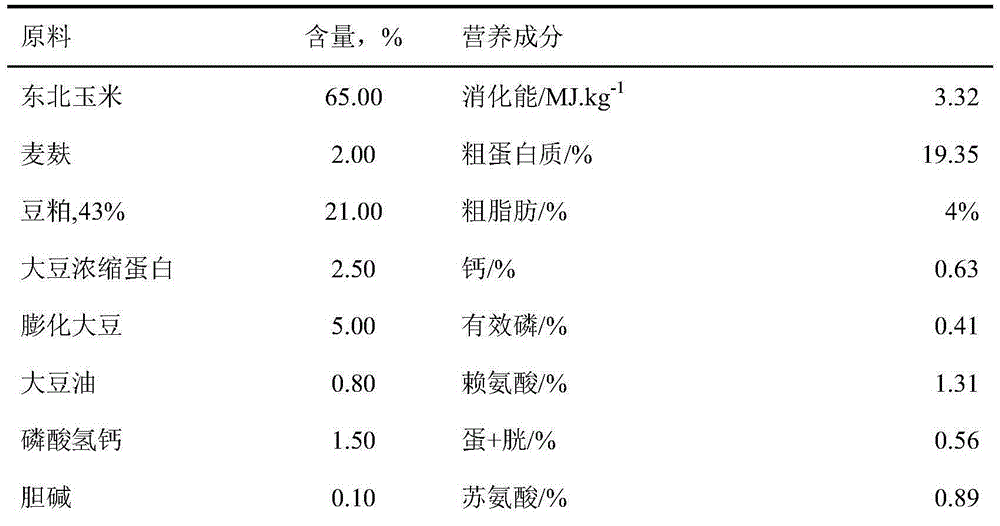

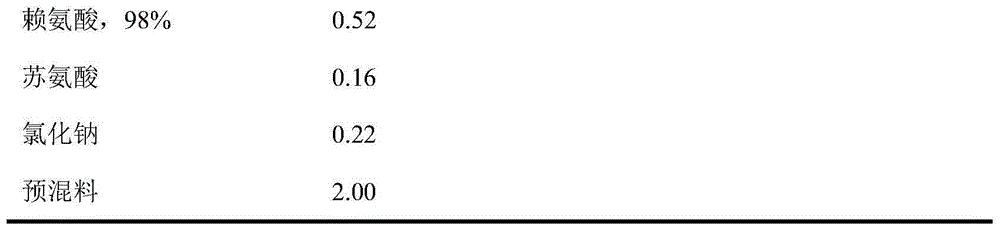

[0038] 16 healthy weaned piglets were selected and divided into 4 treatments, each treatment had 4 replicates, and each replicate had 1 weaned piglet. The average weaning age of piglets was 21 days, and the average weaning weight was 8.01±0.21kg. There was no significant difference in the initial weight of weaned piglets among the treatments (P>0.01). With reference to China (2004) "Nutritional Requirements of Pigs", it is formulated without calcium carbonate (CaCO 3 ) corn-soybean meal based diet. The content of Ca in the basal diet was 0.63%, and the Ca requirement of piglets in the 8-20kg stage was set at 0.88%. The experimental treatment was set as the inorganic calcium group, adding calcium carbonate (CaCO 3 : the amount of Ca38%) is (0.88-0.63) / 0.38=0.66%, total calcium content 0.88% in the diet; 100% calcium organic acid group (calcium polymalate provides calcium source), add the amount of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com