Transparent conductive optical sheet with excellent pattern invisibility

A transparent conductive, optical sheet technology, applied in the direction of optics, optical components, conductors, etc., to achieve the effect of high operability, high stability and reliability, and excellent surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

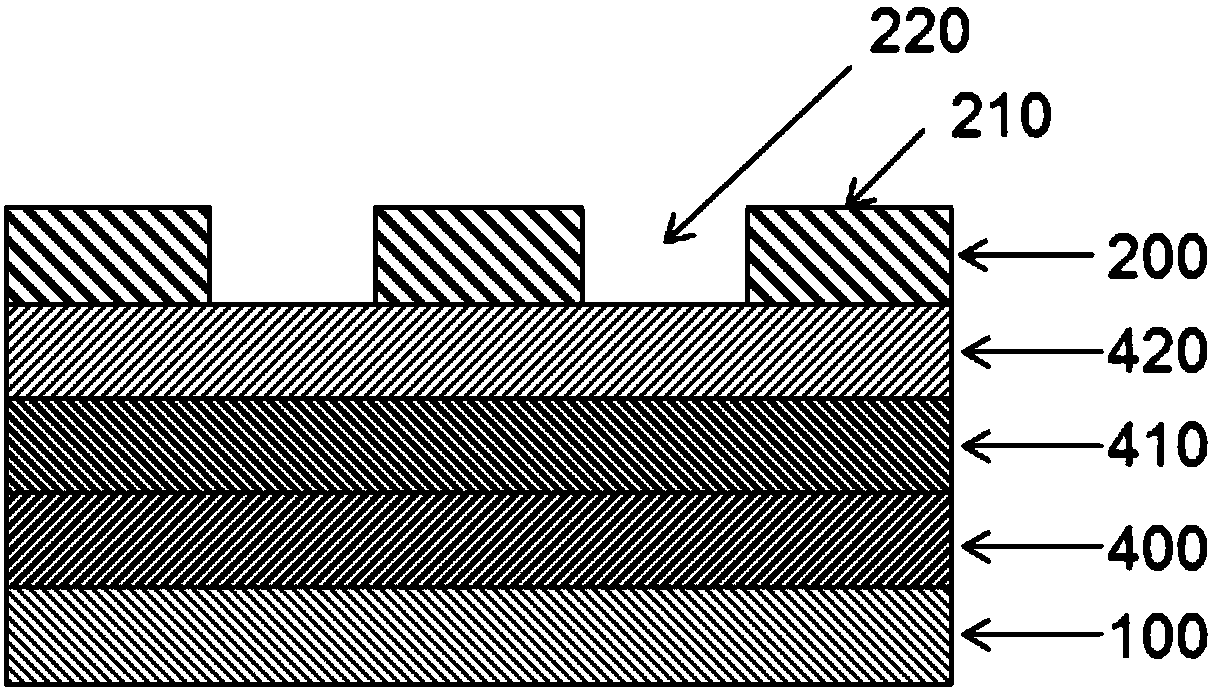

[0115] Example: Fabrication of transparent conductive optical sheets with index matching layers (sheets 1 to 12)

[0116] Step 1: Prepare the transparent base layer

[0117] A transparent PET material with a refractive index (n) of 1.634 to 1.663 at a wavelength of 550 nm and a thickness of 125 μm is used.

[0118] Step 2: Forming the first index matching layer

[0119] Mix 5.5 parts by weight of thermosetting acrylic resin (A811, Aekyung Chemical Co.), 0.3 part by weight of polyisocyanate curing agent (DN980S, Aekyung Chemical Co.), 47.1 parts by weight of xylene (xylene) for dilution ) and 47.1 parts by weight of butyl acetate, 50 to 80 parts by weight of zirconium dioxide (ZrO 2 , JGC Corporation) standard further added zirconium dioxide. The obtained mixed solution is coated on the transparent base layer, dried and thermally cured to form a first refractive index matching layer with a refractive index of 1.573-1.657 and a thickness of 70-85 nm at a wavelength of 550 nm....

experiment example 1

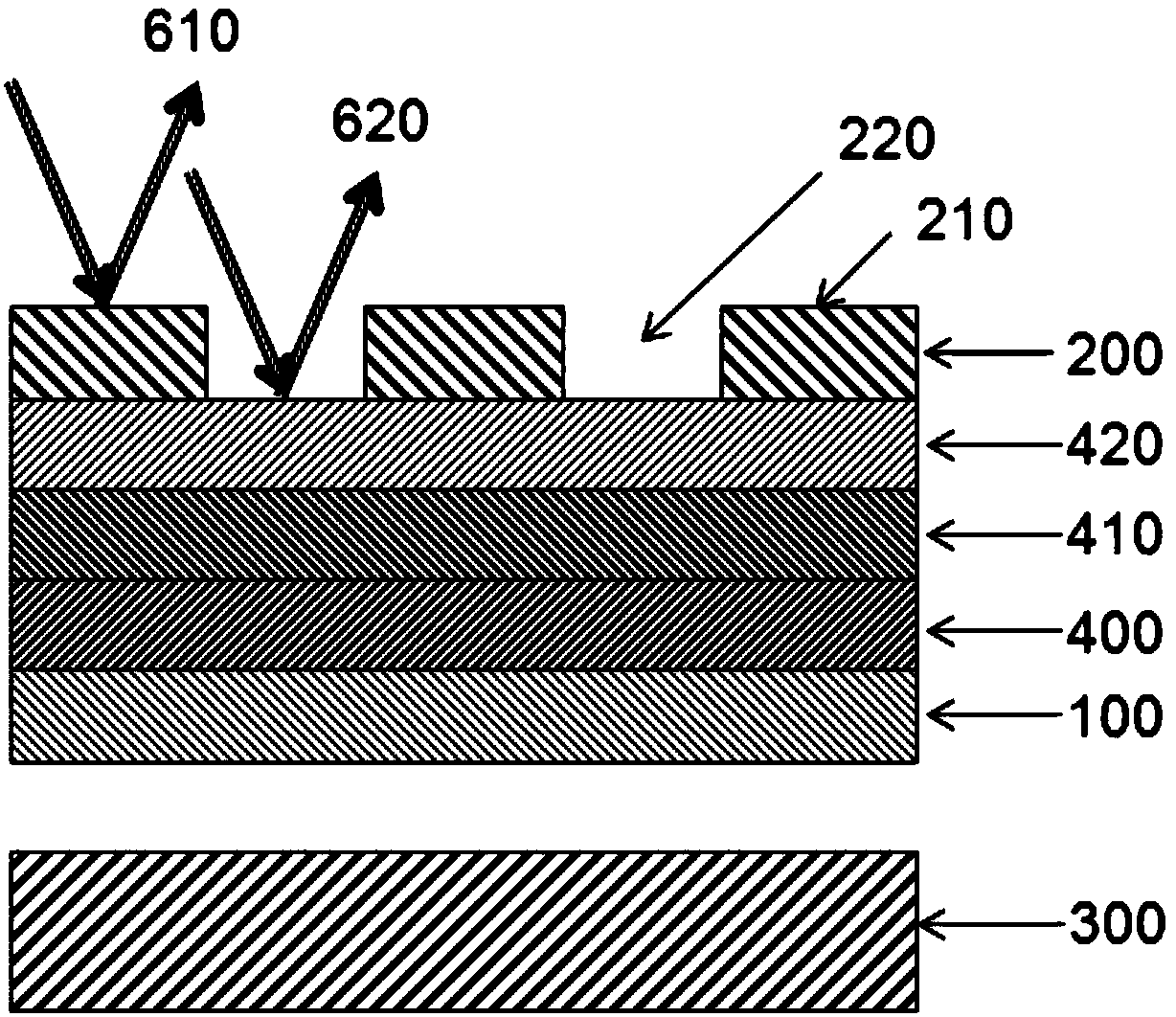

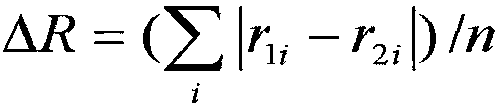

[0132] Experimental example 1: Evaluation of △R value

[0133] For the transparent conductive optical sheet, the reflectance of each wavelength in the visible light region (380 to 780 nm) was measured using a measuring instrument (U4100, Mitsubishi Corporation). At this time, in order to eliminate interference caused by internal reflection, the outer surface of the transparent substrate was printed in black and then measured. Using the measured values, the ΔR value was obtained from the aforementioned Mathematical Formula 1.

experiment example 2

[0134] Experimental example 2: Evaluation of △ER value

[0135] For the transparent conductive optical sheet, the reflected color expressed as the color coordinate of a 2° field of view with respect to a D65 light source was measured using a measuring instrument (U4100, Mitsubishi Corporation). At this time, in order to eliminate the interference caused by internal reflection, the outer surface of the PET material was printed in black and then measured. The value of ΔER was obtained using the measured values and according to the aforementioned Mathematical Formula 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com