Sectional steel concrete shear wall with replaceable wall toe component and wall toe component

A technology for concrete shear walls and shear walls, which is applied to building components, walls, and building structures. It can solve the problems that steel concrete shear walls are difficult to repair and cannot continue to be used, and achieve rapid recovery of earthquake resistance and easy installation. The effect of disassembly and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

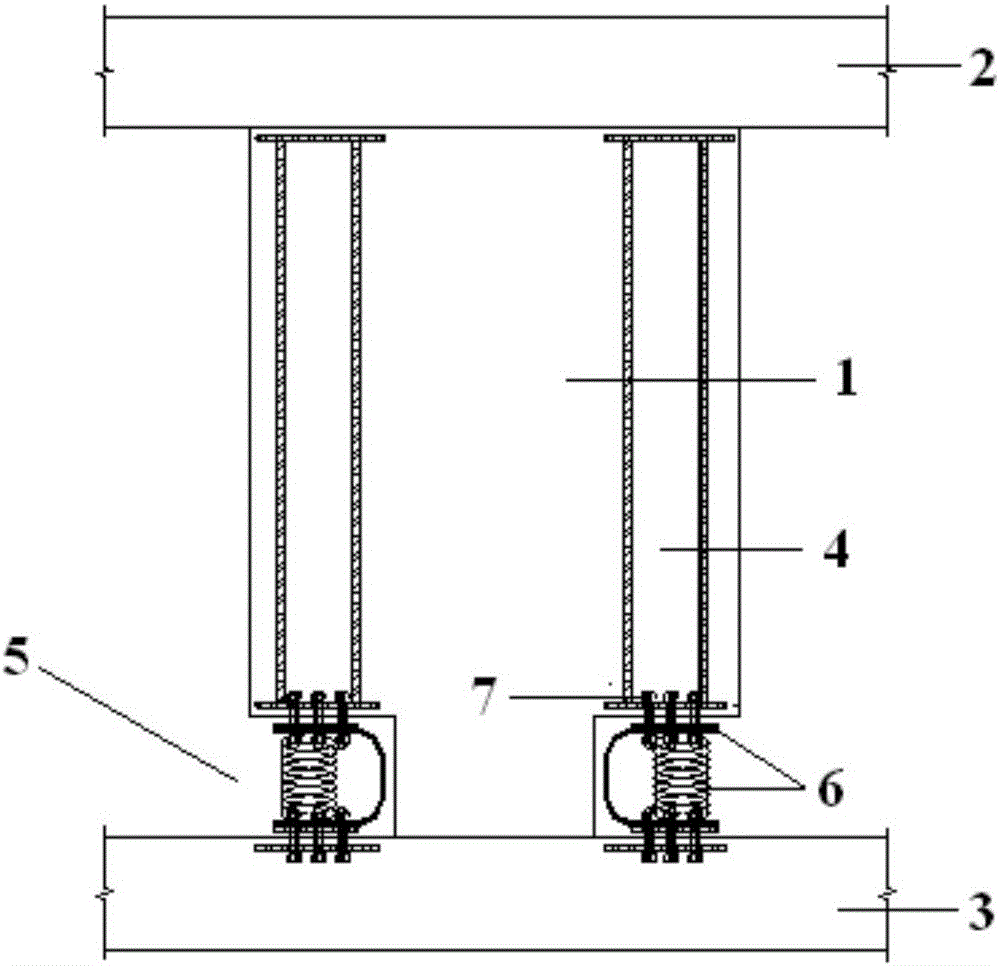

[0031] This embodiment provides a steel concrete shear wall with replaceable wall toe members, such as figure 1 and figure 2 As shown, it includes a shear wall 1, the top of the shear wall 1 is connected to the upper floor member 2, and the bottom of the shear wall 1 is connected to the lower floor member 3. The shear wall 1 has a built-in section steel 4, and the top of the section steel 4 is connected to the The upper floor member 2 is connected, and the bottom end of the section steel 4 is not connected to the lower floor member 3;

[0032] A wall toe placement cavity 5 is reserved on the shear wall 1 between the bottom end of the section steel 4 and the lower floor member 3, and a detachable wall toe member 6 is installed in the wall toe placement cavity 5, and the top of the wall toe member 6 It is connected with the bottom end of the section steel 4, and the bottom end of the wall toe member 6 is connected with the lower floor member 3;

[0033] The wall toe member 6 ...

Embodiment 2

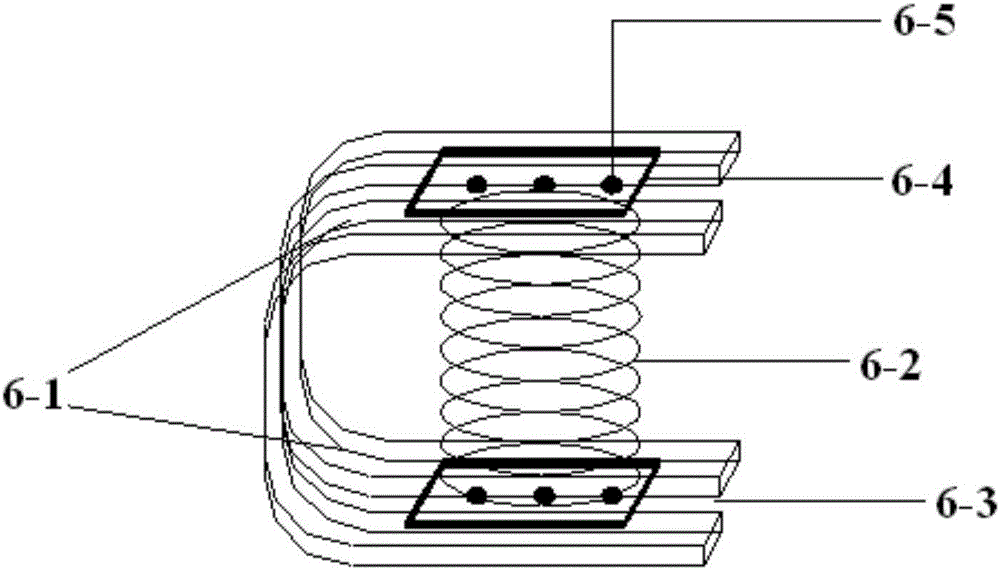

[0046] This embodiment provides a wall toe member, such as figure 2 As shown, it includes a U-shaped board 6-1 and an energy-dissipating spring 6-2, and the two sides of the U-shaped board 6-1 are symmetrically processed with through slots 6-3;

[0047] Both ends of the energy-dissipating spring 6-2 are equipped with a connecting steel plate 6-4, and the connecting steel plate 6-4 is stuck on the outside of the slot 6-3 so that the energy-dissipating spring 6-2 is installed inside the U-shaped board 6-1.

[0048]Further, both the U-shaped board 6-1 and the energy-dissipating spring 6-2 are made of steel with a low yield point.

[0049] Furthermore, the stiffness coefficient k of the energy dissipation spring 6-2 o =25×10 3 kN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness coefficient | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com