Cylinder-shaped part microarc oxidation fixture and using method thereof

A micro-arc oxidation, cylindrical technology, applied in the direction of anodizing, electrolysis components, electrolysis process, etc., can solve the problems affecting the decorative appearance of parts, affecting the quality of the oxide film at the contact point, affecting the micro-arc oxidation process, etc. Simple structure, low cost and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical features, technical content and technical effects of the present invention, the accompanying drawings of the present invention will now be described in more detail in conjunction with the embodiments.

[0024] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is further described.

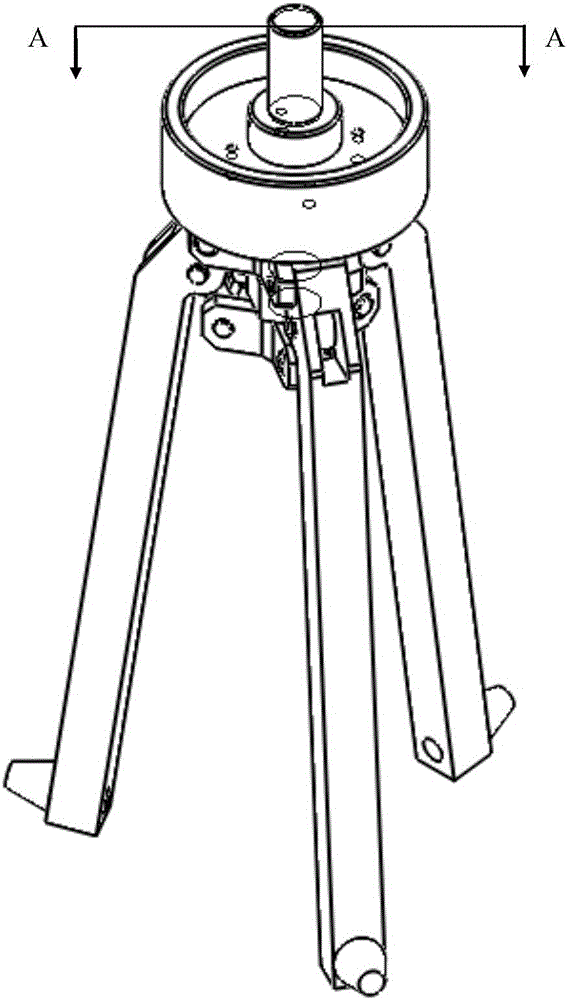

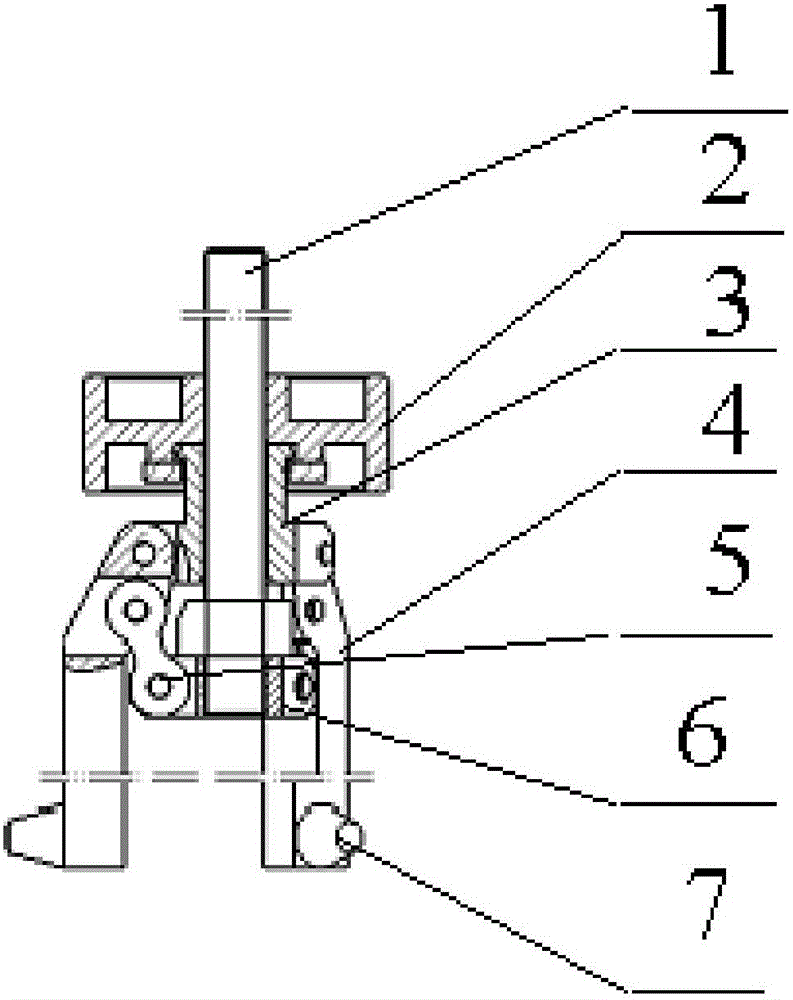

[0025] Such as Figure 1-2 As shown, the present invention provides a micro-arc oxidation fixture for cylindrical parts, including a screw rod 1, a compression nut 2, an upper support 3, a lower support 6 and a clamping device, and the compression nut 2 is sleeved on the On the screw 1, the lower surface of the spigot of the compression nut 2 is connected to the upper surface of the boss of the upper support 3, and the lower support 6 is installed on the lower end of the screw 1 and placed on the Below the upper support 3; the clamping device includes at least 2 groups of clamping units, the clamping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com