Method for processing coal gas flow center dynamic tracking and monitoring coal gas utilization rate

A gas flow center and dynamic tracking technology, which is applied to blast furnace components, furnaces, inspection devices, etc., can solve the problems of not being able to fully represent the blast furnace conditions, having no distribution characteristics of the gas flow center affecting the measurement, and having no statistical laws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

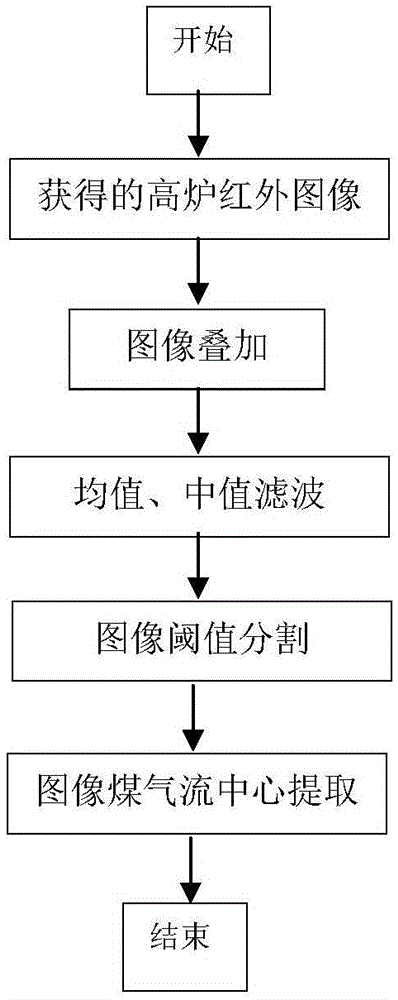

[0035] The method for dynamically tracking the gas flow center and monitoring the gas utilization rate of the present invention comprises:

[0036] Step 1, data collection and processing: Online collection of infrared video production data, cross temperature measurement data and hourly average gas utilization rate within one month (720 hours), and infrared image data of 24 frames per second are obtained through image extraction.

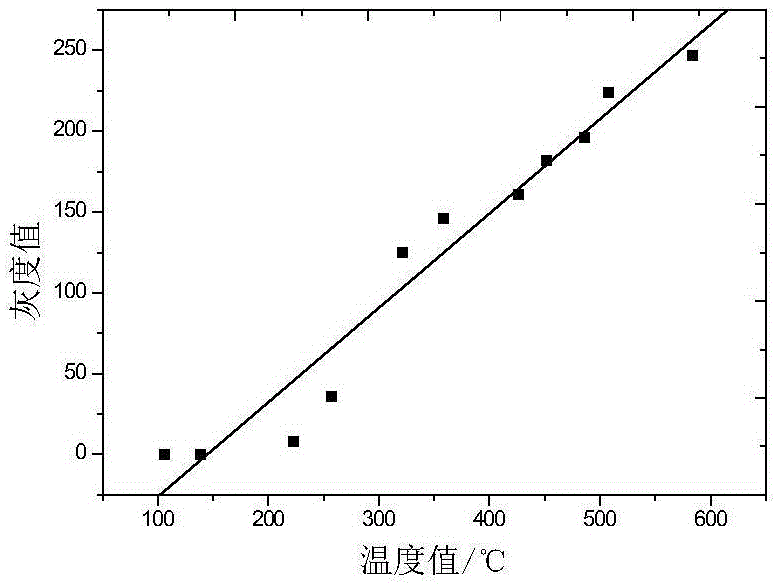

[0037] Step 2, infrared image processing: perform batch superposition processing on the infrared image data obtained in step 1 to obtain 3600 frames per hour (1 frame / second) infrared images of gas flow, and perform mean and median filtering processing on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com