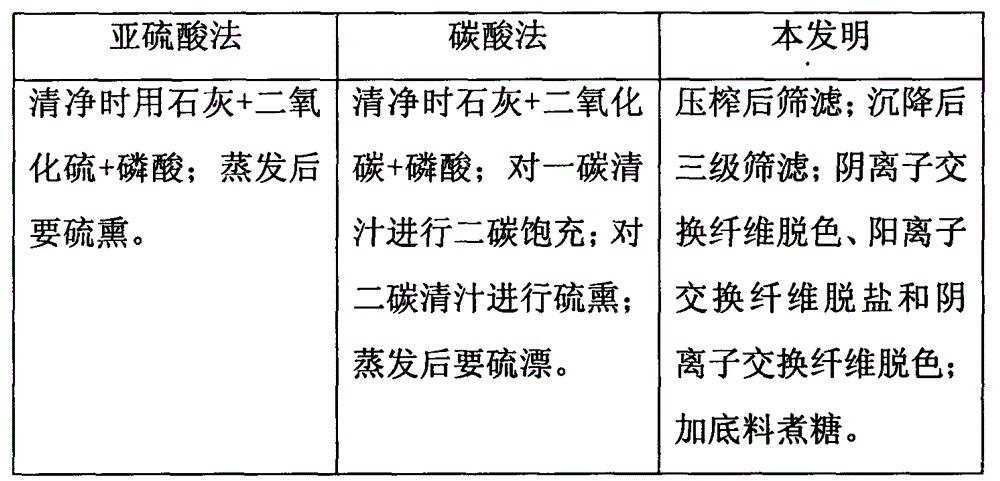

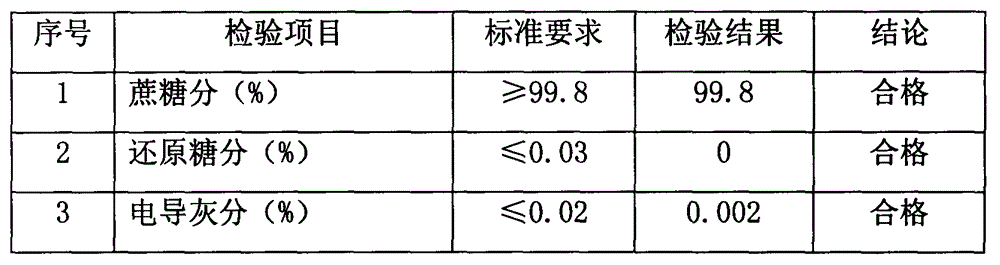

New highly efficient ion-exchange fiber decoloring sulfur-free phosphorus-free sugar-making technology

An ion-exchange fiber, sulfur-free and phosphorus-free technology, which is applied in the fields of ion-exchange material purification, sugar products, sucrose production, etc., can solve the problems of color deepening, increase of exchange burden, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

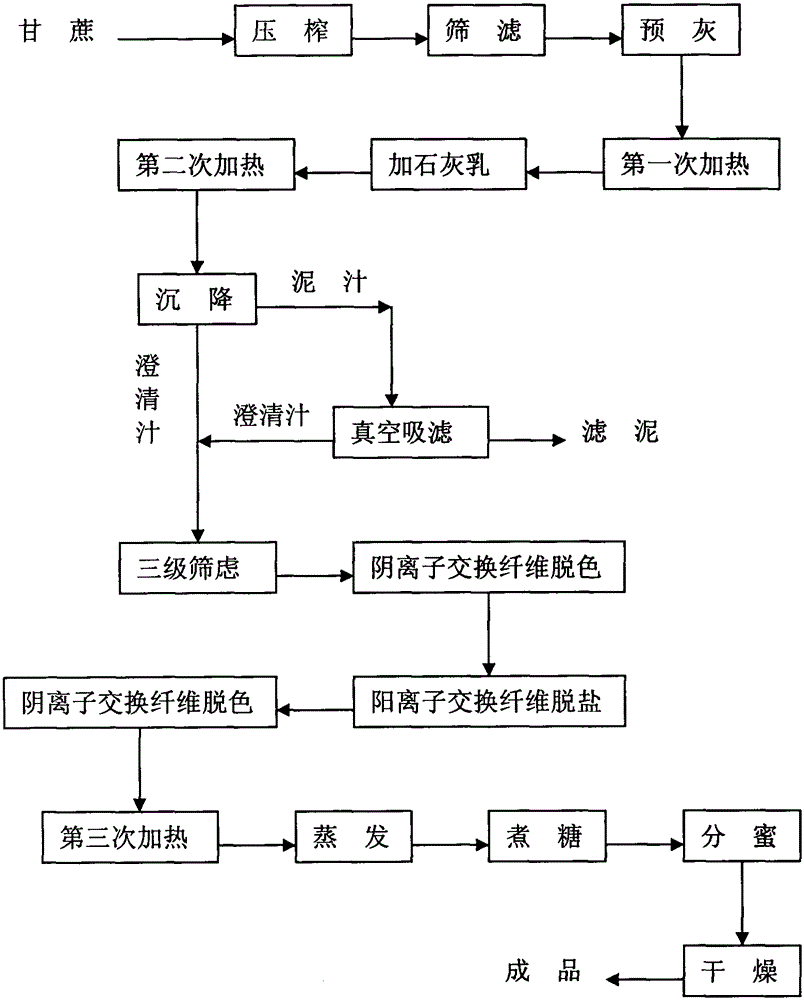

[0052] according to figure 1 process is carried out.

[0053] 1. Crushing: The index control of sugarcane crushing is the same as the traditional process.

[0054] 2. Clarification:

[0055] 1. Screening: the sieve hole is 100 mesh;

[0056] 2. Pre-ash to adjust the pH range of sugarcane juice to 6.4-7.2;

[0057] 3. The primary heating temperature is 60-70°C;

[0058] 4. Add lime milk to adjust the pH range of the sugar juice to 7.0-8.0;

[0059] 5. The second heating temperature is 100-103°C;

[0060] 6. Settling: the clarified juice is transferred to the next process; the mud juice is processed by vacuum suction filtration, and the filtered clarified juice is transferred to the next process, and the filtered mud is treated as waste;

[0061] 7. Three-stage filtration: Filtration is divided into three steps of 80 mesh, 200 mesh and 300 mesh.

[0062] Three, decolorization:

[0063] 1. Pretreatment, including: first filter through a filter with a pore size of 10 μm, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com