Milk froth generator and coffee machine

A generator and milk frother technology, which is applied in the field of dairy products and coffee equipment, can solve the problems of insufficient milk foam, large milk foam bubbles, and poor drinking taste, etc., so as to improve production efficiency, eliminate bubbles, and have a delicate appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

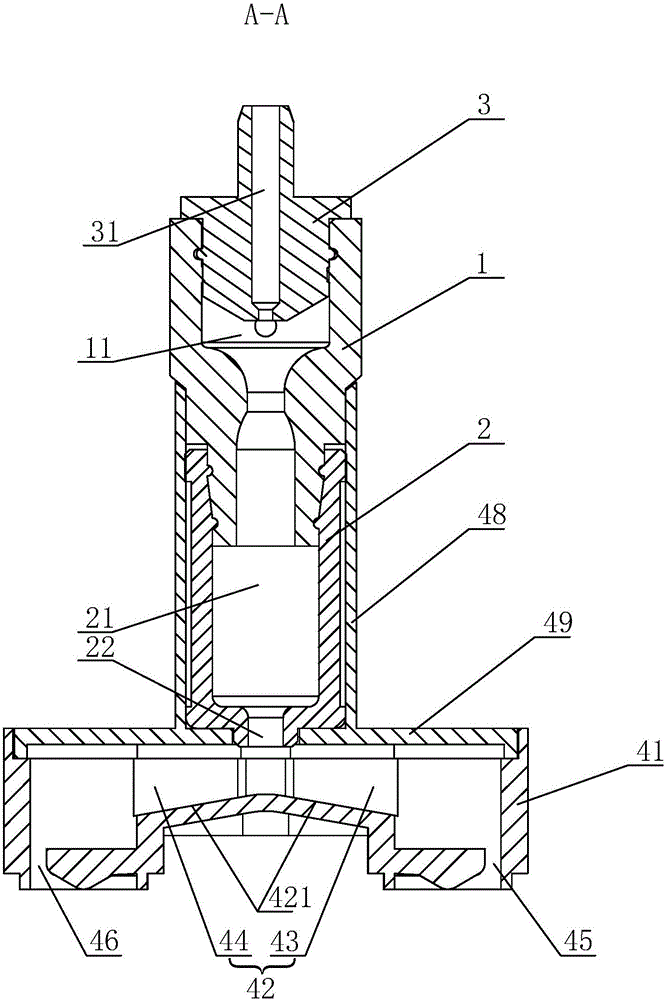

[0021] Such as Figure 1 to Figure 5 As shown, a milk froth generator according to the present invention includes a milk frother body 1 , a milk froth buffer body 2 , a steam nozzle 3 and a milk froth distribution assembly 4 . The milk frother body 1 is provided with a first chamber 11 for mixing steam and milk and a first pipeline 12 connected to the first chamber 11 for milk input. The steam nozzle 3 is installed on the upper part of the milk frother body 1. The steam nozzle 3 has a second pipeline 31 for delivering steam and a third pipeline 32 for delivering air. The second pipeline 31 and the third pipeline 32 are in communication with the first chamber 11 . The milk froth buffer body 2 is fixedly connected to the lower part of the milk frother body 1, and a second chamber 21 for milk foam buffer is opened in the milk foam buffer body 2, and the first chamber 11 and the second chamber 21 links. An outlet 22 is defined at the lower end of the second chamber 21 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com