Pulsed light sterilization method for natural casings

A technology of pulsed strong light and casings, which is applied in the directions of cleaning intestines, processing animal intestines, and preserving meat/fish through radiation/electrical treatment, etc. It can solve the problems of intensity and process that cannot be copied, and achieve short sterilization treatment time, less residue, The effect of little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

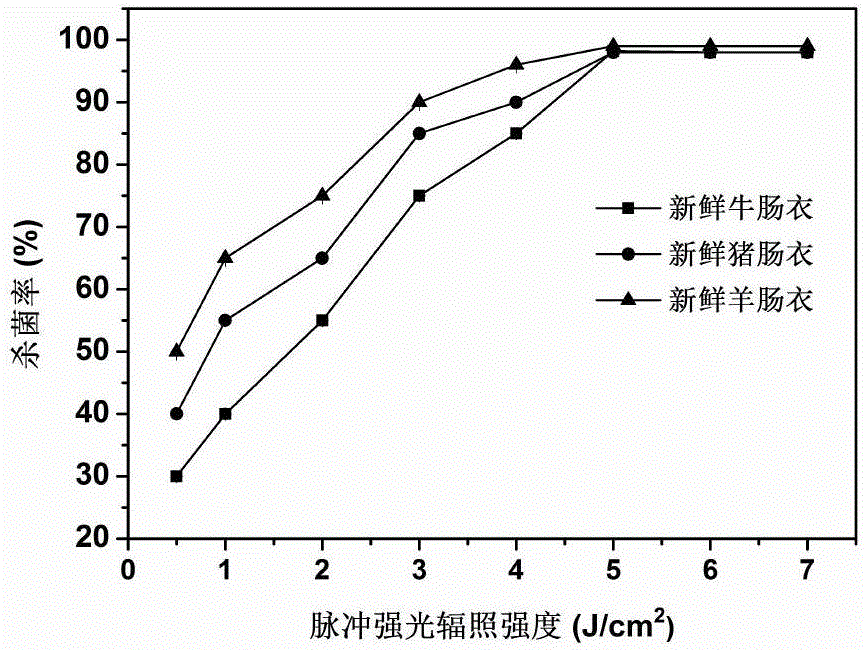

[0030] (1) Original intestine selection: choose fresh beef casings that have not been salted, and the casings are free of debris and odor;

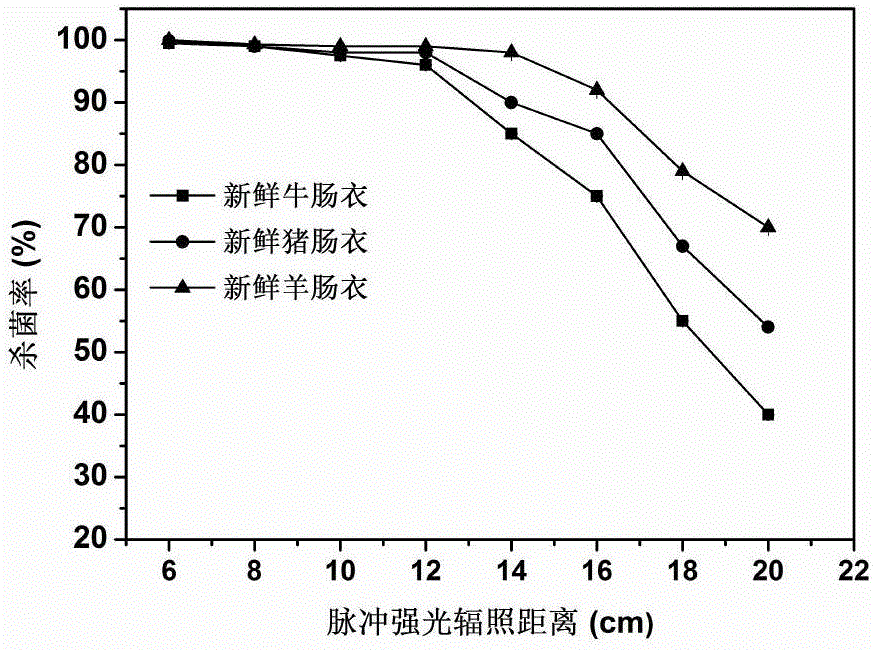

[0031] (2) One pulse strong light sterilization: the casing is transported to the pulse strong light sterilization equipment, and the pulse strong light sterilization intensity is 6J / cm 2 , the flashing distance is 8cm, the flashing time is 25s on the front and back sides, 7 flashes per second, and it is ensured that the casings are not overlapped during the sterilization process;

[0032] (3) Vacuum packaging: lay the casings flat without overlapping and put them into the packaging bags for vacuum packaging;

[0033] (4) Secondary pulsed strong light sterilization: the casing is transported to the pulsed strong light sterilization equipment, and the pulsed strong light sterilization intensity is 3J / cm 2 , the flashing distance is 20cm, the flashing time is 10s on the front and back sides, 3 flashes per second, and it is ensured that the...

Embodiment 2

[0036](1) Original intestine selection: choose fresh pig casings that have not been salted, and the pig casings have no sundries and no peculiar smell;

[0037] (2) One pulse strong light sterilization: the casing is transported to the pulse strong light sterilization equipment, and the pulse strong light sterilization intensity is 5J / cm 2 , the flashing distance is 10cm, the flashing time is 24s on the front and back sides, 5 flashes per second, and it is ensured that the casings are not overlapped during the sterilization process;

[0038] (3) Vacuum packaging: lay the casings flat without overlapping and put them into the packaging bags for vacuum packaging;

[0039] (4) Secondary pulse strong light sterilization: the casing is transported to the pulse strong light sterilization equipment, and the pulse strong light sterilization intensity is 2J / cm 2 , the flashing distance is 23cm, the flashing time is 8s on the front and back sides, 3 flashes per second, and ensure that ...

Embodiment 3

[0042] (1) Original intestine selection: choose fresh sheep casings that have not been salted, and the sheep casings have no sundries and no peculiar smell;

[0043] (2) One pulse strong light sterilization: the casing is transported to the pulse strong light sterilization equipment, and the pulse strong light sterilization intensity is 4J / cm 2 , the flashing distance is 15cm, the flashing time is 20s on the front and back sides, 5 flashes per second, and ensure that the casings are not overlapped during the sterilization process;

[0044] (3) Vacuum packaging: lay the casings flat without overlapping and put them into the packaging bags for vacuum packaging;

[0045] (4) Secondary pulse strong light sterilization: the casing is transported to the pulse strong light sterilization equipment, and the pulse strong light sterilization intensity is 1J / cm 2 , the flashing distance is 27cm, the flashing time is 6s on the front and back sides, 2 flashes per second, and ensure that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com