Exhaust purification device

An exhaust purification device and technology for exhaust devices, which are applied to exhaust devices, mufflers, catalyst carriers, etc., can solve the problems of complex structure and different lengths, and achieve the effect of improving purification performance, simple structure and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

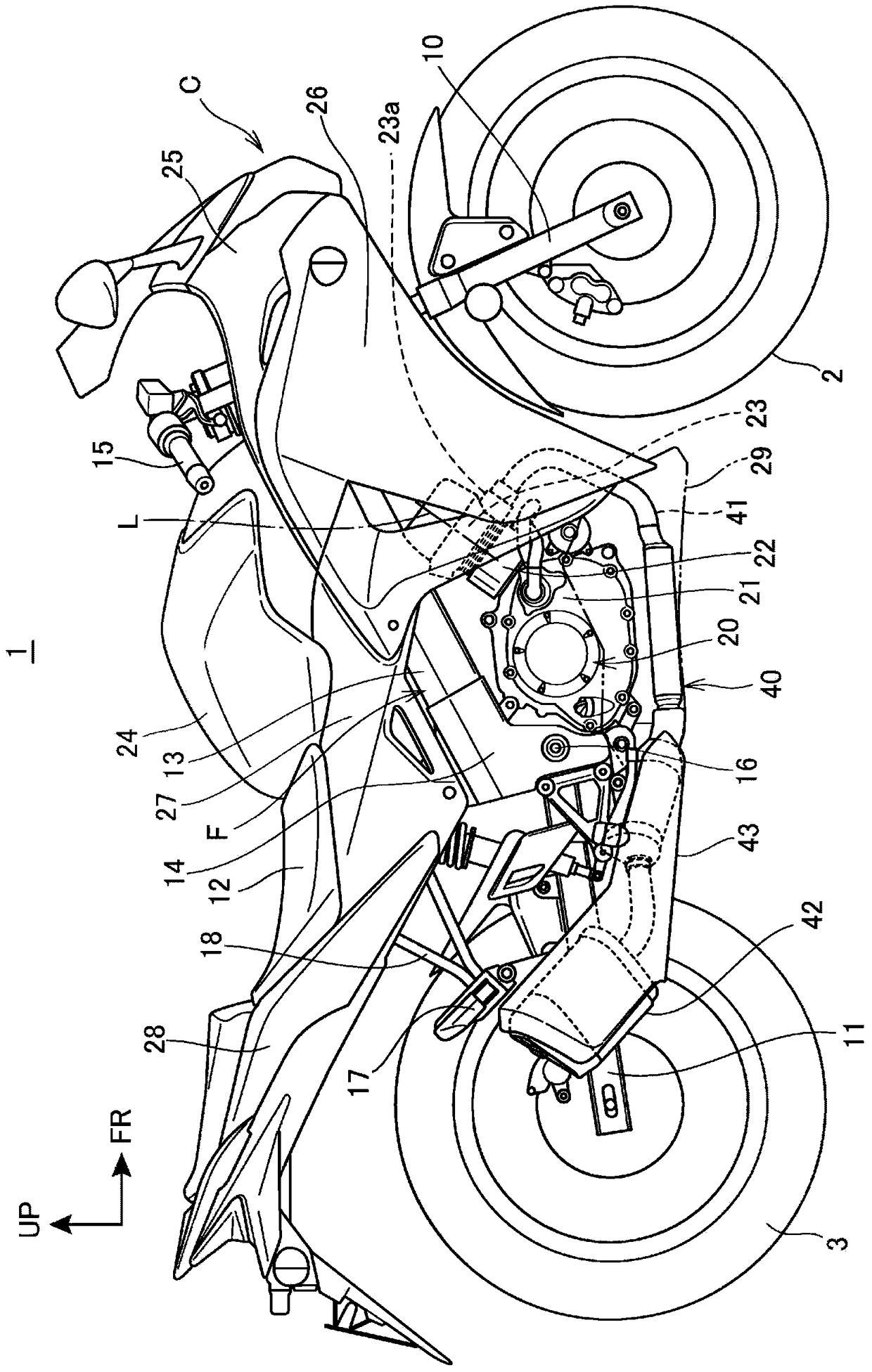

[0048] figure 1 It is a right side view of the motorcycle of the first embodiment of the present invention.

[0049] The two-wheeled motorcycle 1 is a straddle-type vehicle, and an engine 20 is arranged in the center of the front and rear of the body frame F. The front fork 10 supporting the front wheel 2 is supported on the front end of the body frame F in a steerable manner, and the rear wheel 3 is supported by the front fork 10. A swing arm 11 is provided on the rear side of the body frame F, and a seat 12 on which an occupant sits is provided above the body frame F. As shown in FIG. Most of the body frame F is covered with a body cover C made of resin.

[0050] The body frame F has: a head pipe (not shown) provided at the front end; a pair of left and right main frames 13 extending obliquely downward from the head pipe to the rear; To the central vehicle frame 14; From the top of the central vehicle frame 14 to the left and right pair of seat frames (not shown) extending...

no. 2 Embodiment approach

[0115] Below, refer to Figure 5 ~ Figure 7 A second embodiment to which the present invention is applied will be described. In this second embodiment, the same reference numerals are assigned to the same components as those in the above-mentioned first embodiment, and description thereof will be omitted.

[0116] In the above-mentioned first embodiment, the case where the catalyst storage pipe 45 is arranged below the engine 20 has been described. The implementation is different.

[0117] Figure 5 It is a right side view of the motorcycle 101 of the second embodiment.

[0118] The two-wheeled motorcycle 101 is a straddle type vehicle, and an engine 120 is arranged in the center of the front and back of the body frame 108. The front fork 110 supporting the front wheel 102 is supported on the front end of the body frame 108 in a steerable manner, and the rear wheel 103 is supported. The swing arm 111 is provided on the rear side of the body frame 108 , and the seat 112 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com