Method for producing a chromium coating on a metal substrate

A metal substrate and coating technology, applied in the direction of metal material coating process, coating, superimposed layer plating, etc. And corrosion resistance is not enough to meet industrial needs and other problems, to achieve the effect of excellent corrosion resistance, safety and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

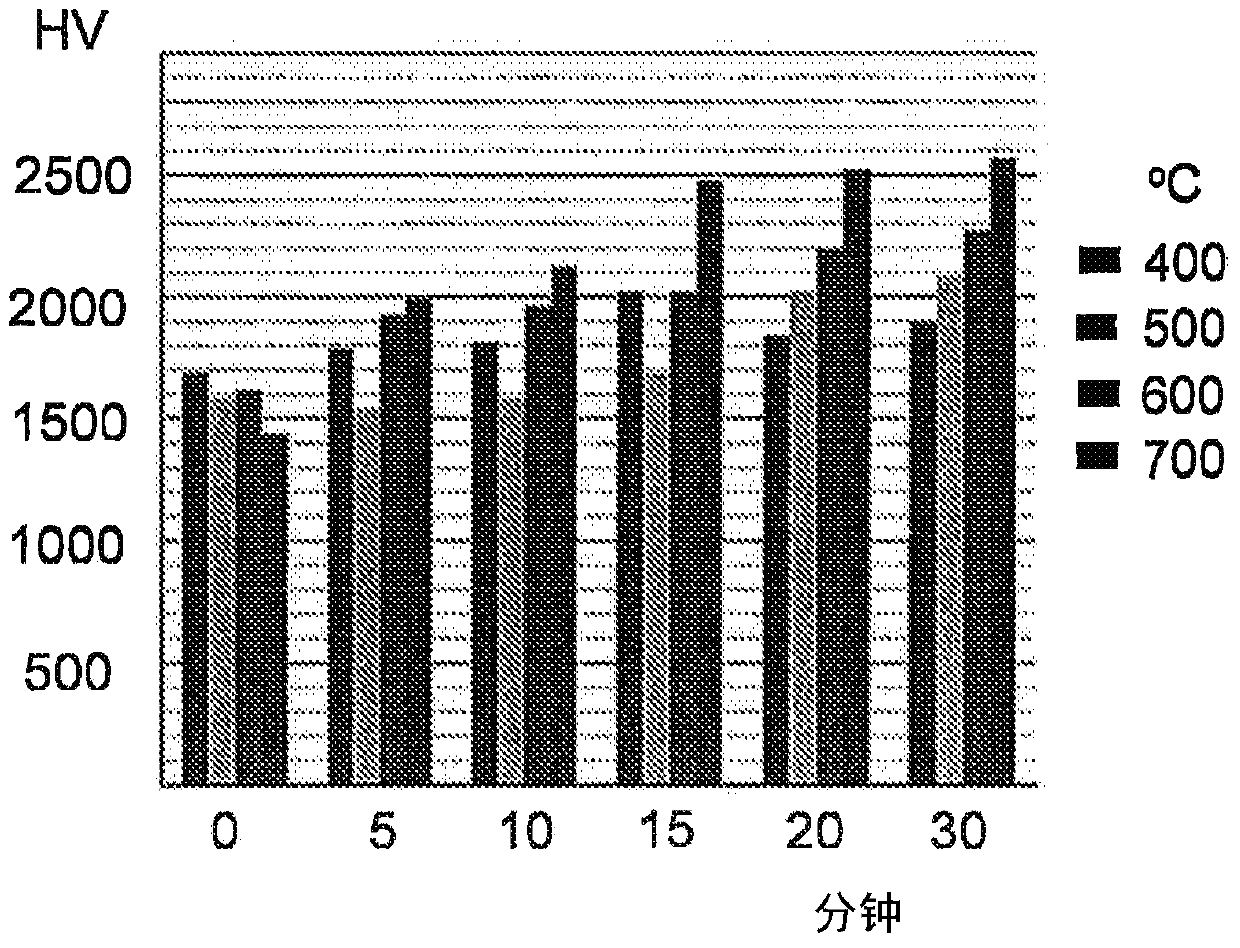

[0064] To demonstrate the effectiveness of the invention, several metal substrates were coated with nickel and chromium and subjected to a dual heat treatment sequence. The coated metal substrates used in the tests consisted of a steel substrate covered by a Ni-P layer with a thickness of 7 μm and a Cr layer with a thickness of 4 μm.

[0065] A first heating step is performed at a temperature between 200°C and 700°C for 30 or 45 minutes, after which the metal substrate is cooled. A second heating step of the same sample was performed at a temperature between 400° C. and 700° C. for a duration between 5 and 30 minutes, after which the metal substrate was cooled again.

[0066] The hardness values of the coated and heat-treated metal substrates are measured in the microscopic range by Vickers hardness testing according to EN-ISO6507, depending on the thickness of the coating, using a durometer indenter weight of 5, 10 or 25 g.

[0067] The corrosion resistance of the coated a...

example 2

[0084] The steel substrate was coated with a Ni-P layer with a thickness of 7 μm and a Cr layer with a thickness of 4 μm. The heat treatment was performed in two steps: the first step took 45 minutes at 400°C and the second step took 30 minutes at 700°C.

[0085] The hardness value measured from the coating after the double heat treatment was about 2500 HV, measured with a load of 10 g.

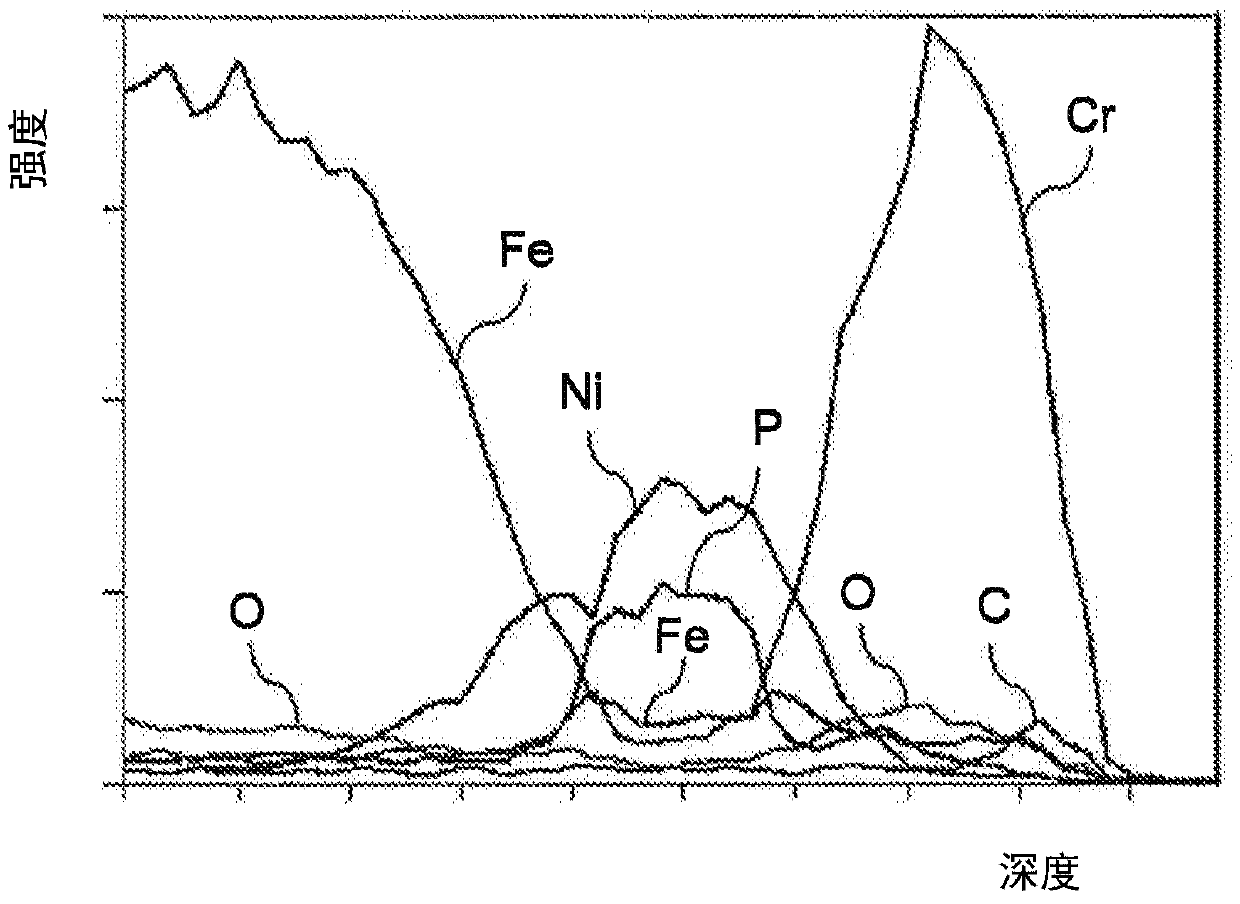

[0086] The layered structure can be identified in cross-sectional micrographs of the coated surface. The composition of the coating is analyzed by energy dispersive X-ray spectroscopy (EDS) by having the electron beam lined up on the image and generating a scattergram of the relative proportions of the previously determined elements along the spatial gradient. image 3 The EDS spectrum of the sample is shown. On the left is the steel substrate. On the right is the outer surface of the coating.

[0087] Working from the steel substrate towards the outer surface of the coating, the followin...

example 3

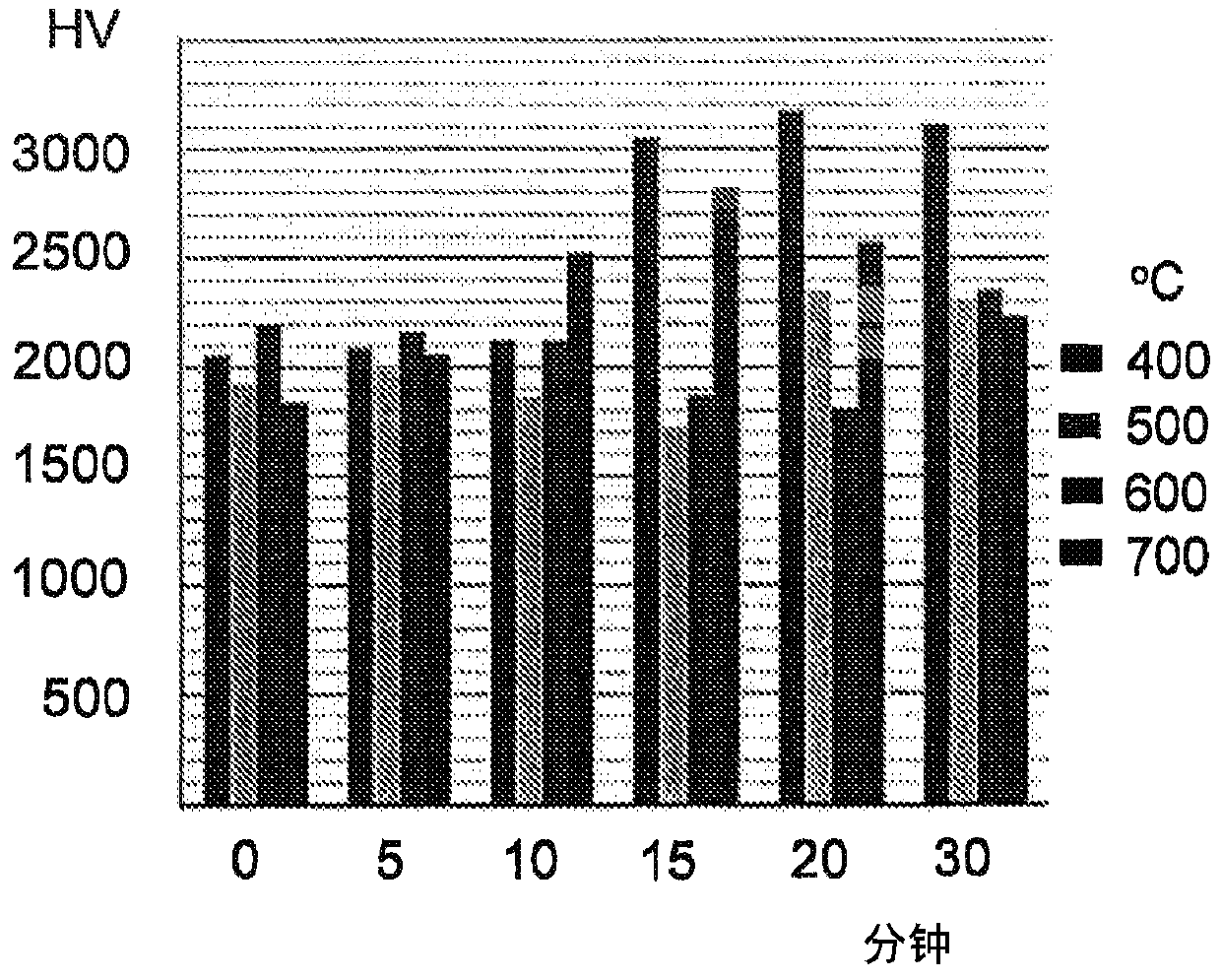

[0096] Another steel substrate was coated with a similar coating as in example 2: nickel phosphorus layer with a thickness of 7 μm and a layer of chromium with a thickness of 4 μm. The heat treatment was performed in two steps: the first step took 30 minutes at 400°C and the second step took 30 minutes at 700°C.

[0097] Hardness values measured from the coated and heat-treated metal substrates were approximately 2500-3000 HV, measured with a load of 10 g.

[0098] The lamellar structure can be identified in cross-sectional micrographs of the coating. Figure 5 EDS of samples are shown. Working from the steel substrate towards the outer surface of the coating, the following layers were able to be identified in the sample:

[0099] - Fe-rich layer (steel substrate),

[0100] - a layer mainly comprising Fe and Ni,

[0101] - a layer mainly comprising Ni and P,

[0102] - a layer mainly comprising Ni and Cr,

[0103] - a layer mainly comprising Cr and O,

[0104] - A lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com