Tunable liquid microsphere laser

A laser and microsphere technology, applied in the field of lasers, can solve the problems such as the lack of breakthrough progress in liquid microsphere lasers, the inaccuracy of macroscopic mechanical vibration, and the difficulty in realizing laser output, and achieve low-loss connection, high Q value, excitation The effect of low energy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

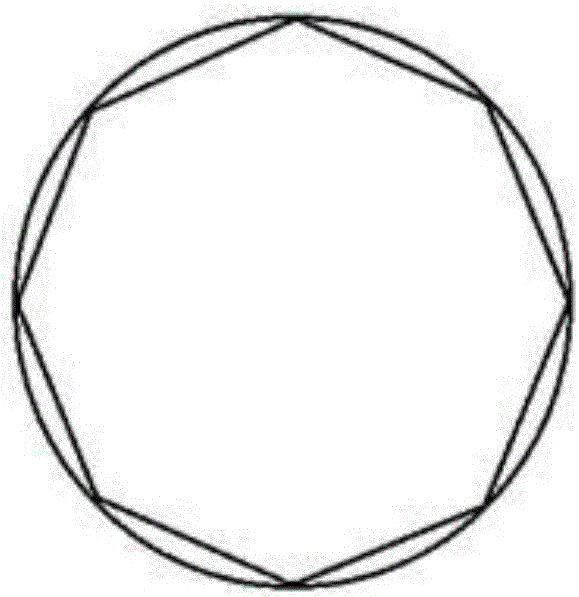

Image

Examples

specific Embodiment 1

[0026] Specific embodiment 1, the realization of a liquid microsphere laser, and the light intensity and phase of the output laser are tuned.

[0027] Proceed as follows:

[0028] 1. Optical system construction:

[0029] ①Select two lasers with a wavelength of 980 nm as the capture light source, weld the output ends of the first capture light source 1 and the second capture light source 2 to the first isolator 4 and the second isolator 5, and weld the output ends of the isolators A section of standard single-mode optical fiber, the tail end of the single-mode optical fiber is about 30 mm removed from the coating layer and cut flat to form the end of the first capturing optical fiber 7a and the end of the second capturing optical fiber 7b, realizing a set of dual-fiber optical tweezers;

[0030] ②Choose a laser with a central wavelength of 532 nm as the pumping light source 3, weld the output end of the pumping light source 3 to the third isolator 6, weld a section of standard...

specific Embodiment 2

[0041] Specific embodiment 2, the realization of a liquid microsphere laser, and the wavelength of the output laser is selected.

[0042] Proceed as follows:

[0043] 1. Optical system construction:

[0044] ①Select two lasers with a wavelength of 980 nm as the capture light source, weld the output ends of the first capture light source 1 and the second capture light source 2 to the first isolator 4 and the second isolator 5, and weld the output ends of the isolators A section of standard single-mode optical fiber, the tail end of the single-mode optical fiber is about 30 mm removed from the coating layer and cut flat to form the end of the first capturing optical fiber 7a and the end of the second capturing optical fiber 7b, realizing a set of dual-fiber optical tweezers;

[0045] ②Choose a laser with a central wavelength of 532 nanometers as the pumping light source 3, weld the output end of the pumping light source 3 to the third isolator (6), weld the output end of the is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com