Low-partial-discharge-value single-structure-based mutual inductor and manufacturing method thereof

A transformer and low partial discharge technology, applied in the field of transformers, can solve the problems of uneven electric field distribution, high partial discharge value, waste of materials, etc. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

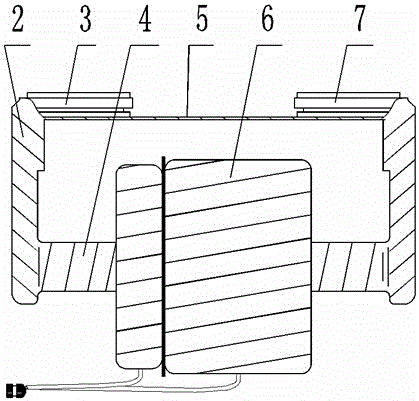

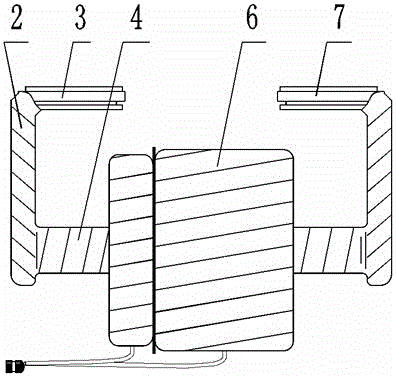

[0020] As shown in the attached figure, the single-turn structure transformer with low partial discharge value includes semiconductor crepe paper 2 , P1 terminal 3 , conductive rod 4 , transformer coil 6 , and P2 terminal 7 . C-shaped semiconductor cardboard 5 is arranged on the inner side of the pole 4 and the electric pole 4; the C-shaped semiconductor cardboard 5 is fixed on the conductive rod 4 through the semiconductor crepe paper 2; the transformer coil 6 is inserted into the primary winding of the transformer.

[0021] The primary terminal is composed of P1 outlet terminal 3 and P2 outlet terminal 7;

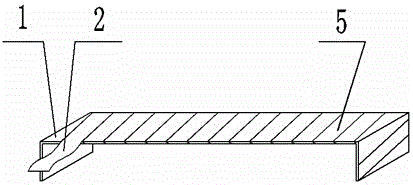

[0022] The C-shaped semiconductor paperboard 5 is formed by winding hard insulating paperboard 1 and semiconductor crepe paper 2, and the width of the hard insulating paperboard 1 is consistent with the width of the primary terminal;

[0023] The P1 terminal 3 and the P2 terminal 7 are welded to the conductive rod 4;

[0024] The transformer primary winding is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com