Automatic bridging system and its installation method and usage method

An installation method and automatic technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as small height and difficult construction, and achieve the effects of avoiding wrong data, high accuracy, and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

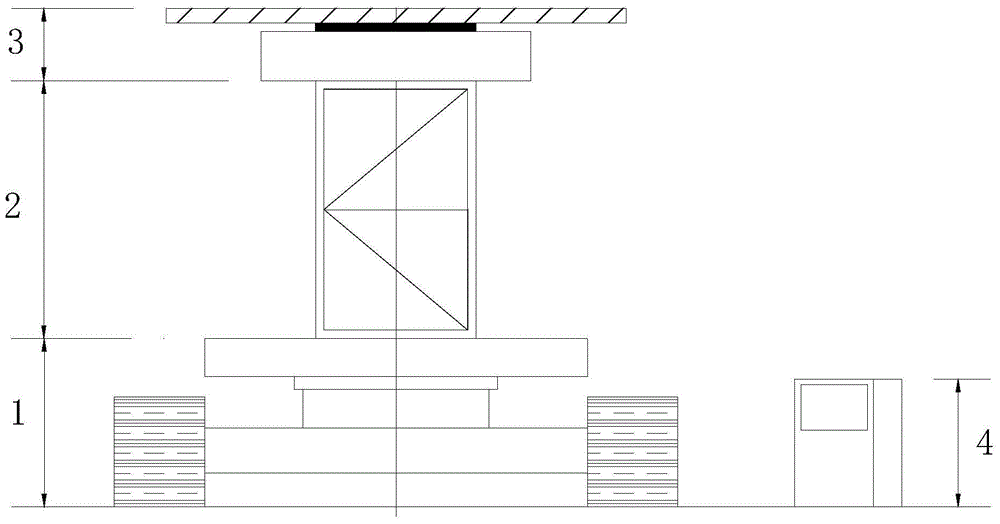

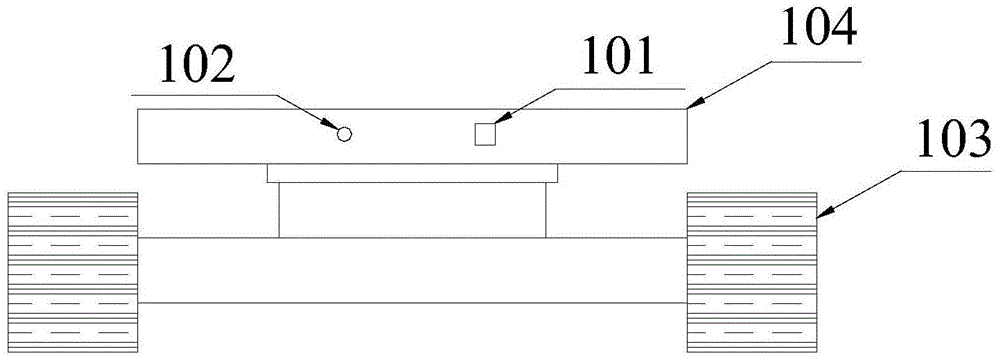

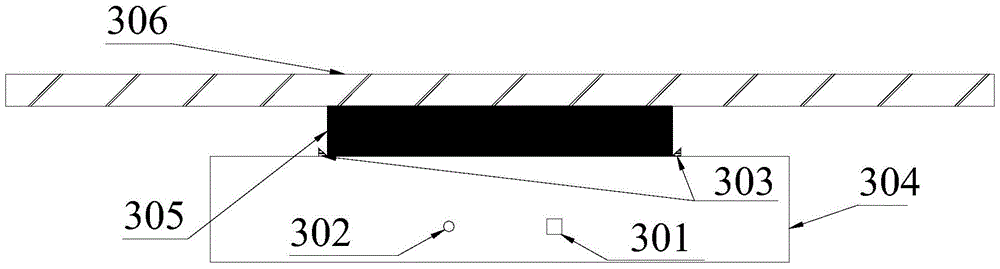

[0064] refer to figure 1 , figure 2 , image 3 , Figure 5 , each bridging unit of the automatic bridging system includes a mobile platform 1, a support module 2, an adjustment platform 3 and an intelligent operation platform 4, wherein the mobile platform 1, the support module 2, and the adjustment platform 3 are arranged in sequence from bottom to top, intelligent The operating platform 4 is set outside the safe distance of the erection site, and is wirelessly connected with the mobile platform 1 and the adjustment platform 3 .

[0065] The mobile platform 1 is used for carrying other structures and moving the whole structure, which includes mobile wheels 103 and a platform 104 . The platform 104 is also provided with a first infrared measuring instrument 101 and a first wireless transceiver 102, wherein the first infrared measuring instrument is used to monitor the position of the overall structure relative to the pier, and adjust whether the prefabricated components pl...

Embodiment 2

[0076] The installation method of aforementioned automatic bridging system comprises the steps:

[0077] (1) Select the size, model and quantity of the mobile platform according to the width and height of the bridge to be built. Specifically, when the clear longitudinal span of the pier is ≤10m, one or two mobile platforms can be selected; when the clear longitudinal span of the pier is ≥10m, two or more mobile platforms can be selected. Wherein, the longitudinal direction refers to the direction along the length of the bridge.

[0078] (2) After selecting the size, model and quantity of the mobile platform, it is necessary to adjust the position of the mobile platform and limit the moving direction of the mobile platform during bridging. Specifically, first debug whether the wireless connection between the mobile platform and the intelligent operation platform is normal, then the first infrared measuring instrument on the mobile platform sends the monitoring results to the t...

Embodiment 3

[0084] The using method of aforementioned automatic bridging system comprises the steps (when the bridging unit used is one):

[0085] (1) Prepare and install prefabricated components. After the bridging unit is erected and debugged, the bridging unit is located on the longitudinal side of the bridge pier, and the prefabricated components are hoisted to the prefabricated component installation position on the top of the bridging unit through the lifting structure, and the prefabricated components are locked and fixed by the automatic locking device At the position in the prefabricated component installation position, at this time, the length direction of the prefabricated component is parallel to the longitudinal direction of the pier.

[0086](2) Adjust the prefabricated components to prepare to enter the state between two transverse piers. According to the length of the prefabricated component and the distance between the two transverse piers, the intelligent operation plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com