Composite fiber macromolecular reinforced concrete sound barrier and manufacturing method thereof

A technology for reinforcing concrete and composite fibers, which is applied in the field of traffic noise barriers, can solve the problems of high sound barrier quality, poor sound insulation effect, and poor durability, and achieve the effects of low cost, light weight and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

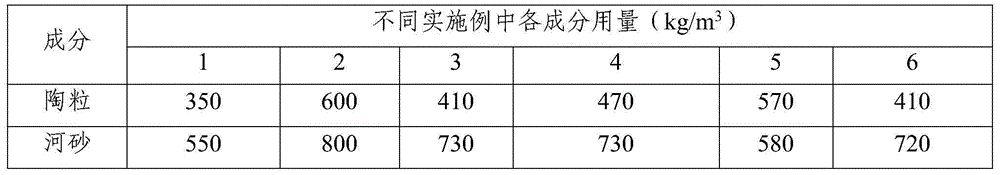

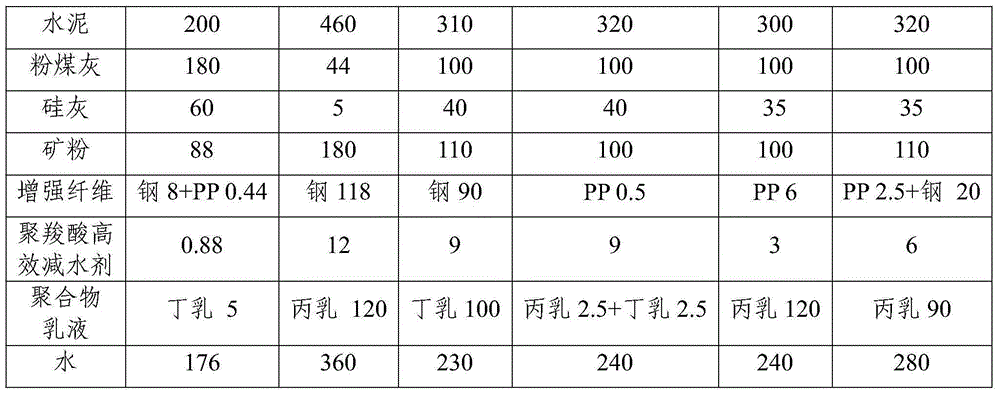

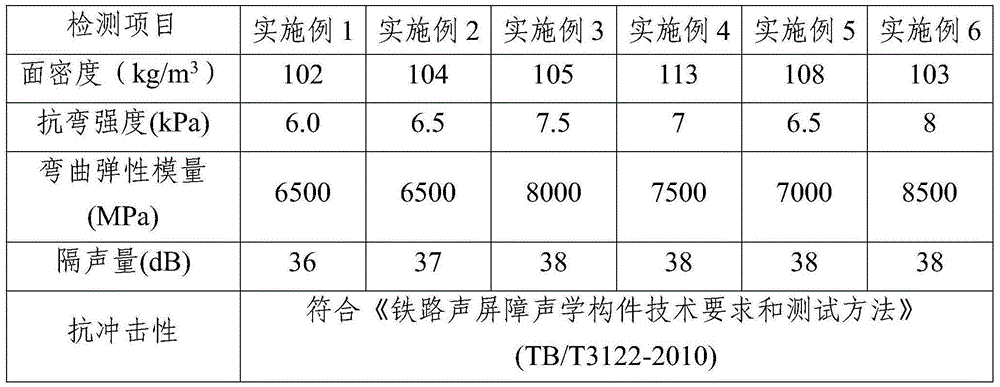

[0025] Trial-manufacture 2-meter concrete sound barrier unit panels (1960×500×120mm) with the composite fiber polymer reinforced concrete sound barrier formula of the present invention, wherein the unit panel structures are all panels (with steel mesh inside)+sound-absorbing layer+back Panel (with steel mesh inside), the relevant dimensions are: panel 30mm + sound-absorbing layer 60mm + back panel 30mm, the relevant formula is shown in Table 1.

[0026] Table 1 Raw material formula of composite fiber polymer reinforced concrete sound barrier

[0027]

[0028]

[0029] Remarks: In Example 4, the quality grade of fly ash is grade II, the grade of mineral powder is S75, and the particle density of silica fume is 2.2g / cm 3 ; Steel fiber length 30mm, diameter 0.7mm; polypropylene fiber length 12mm.

[0030] Preparation steps:

[0031] (1) Mold making: first soak the ceramsite for 30-90 minutes, then mix and stir river sand, cement, fly ash, silica fume and mineral powder fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com