Ferro-manganese binary metallic oxide modified haydite for removing phosphorus and preparation method thereof

A binary metal and oxide technology, applied in the field of water treatment, can solve the problems of poor effluent quality and loss, and achieve the effects of improving efficiency, prolonging service life and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

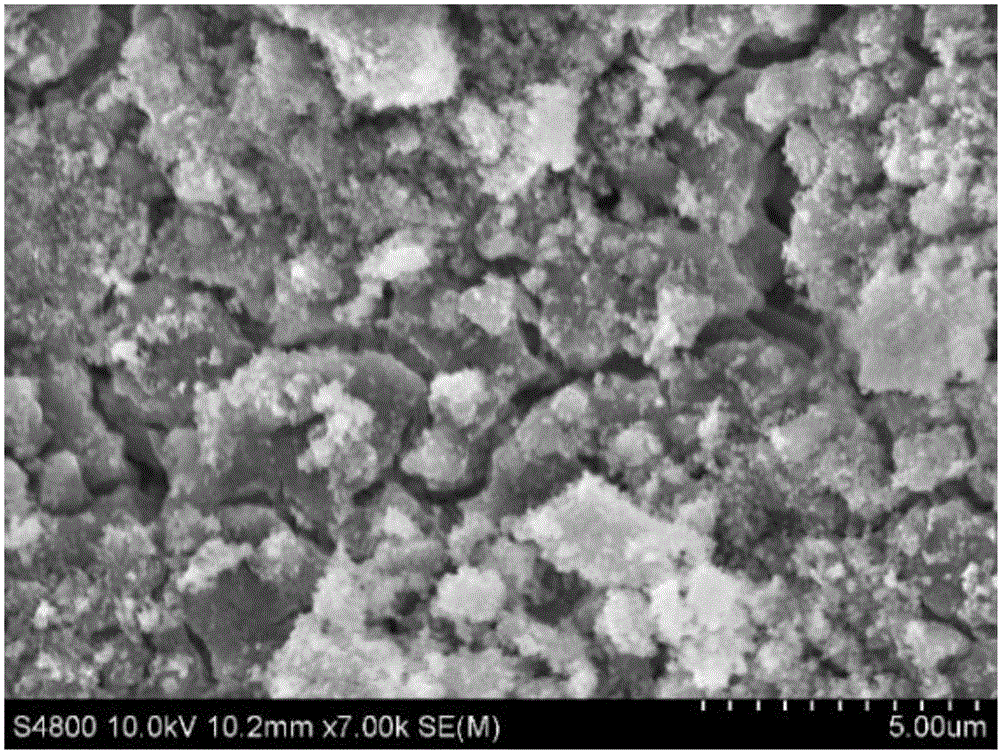

[0034] Experimental example Preparation of iron-manganese binary metal oxide

[0035] Weigh 39.5g of potassium permanganate and 69.5g of ferrous sulfate powder, dissolve and set the volume in 1000mL and 500mL volumetric flasks, respectively prepare potassium permanganate solution with a concentration of 0.25mol / L and ferrous sulfate with a concentration of 0.5mol / L iron solution. In order to prevent oxidation, the ferrous sulfate solution needs to be prepared and used immediately.

[0036] Measure 160mL potassium permanganate and 400mL ferrous sulfate solution, pour 160mL potassium permanganate solution into a 1000mL beaker, and prepare a mechanical stirrer above the beaker. Start stirring at room temperature, slowly add 400mL of ferrous sulfate solution, and adjust the pH of the mixed solution to about 10 with 2.5mol / L sodium hydroxide solution after adding 50mL of ferrous sulfate solution until the ferrous sulfate solution is completely exhausted. The molar ratio of mangan...

Embodiment 1

[0044] The volcanic rock ceramsite with a particle size of 1-2mm was washed three times with deionized water, dried naturally, and then dried in an oven at 105°C until constant weight. After cooling to room temperature, it was stored in a dry box and used as an adsorption substrate for subsequent experiments.

[0045]Take by weighing 31.6g potassium permanganate and 55.6g ferrous sulfate (FeSO 4 ·7H 2 O) powder, dissolve and settle to volume in 1000mL and 500mL volumetric flasks, respectively prepare potassium permanganate solution with a concentration of 0.2mol / L and ferrous sulfate solution with 0.4mol / L. In order to prevent oxidation, the ferrous sulfate solution needs to be prepared and used immediately.

[0046] Measure 200mL of potassium permanganate and 400mL of ferrous sulfate solution, pour 200mL of potassium permanganate solution into a 1000mL beaker, add 80.0g of dried volcanic rock ceramsite at the same time, and prepare a mechanical stirrer above the beaker.

...

Embodiment 2

[0051] Weigh 31.6g of potassium permanganate and 83.4g of ferrous sulfate powder, dissolve and set the volume in 1000mL and 500mL volumetric flasks, respectively prepare potassium permanganate solution with a concentration of 0.2mol / L and ferrous sulfate with a concentration of 0.6mol / L iron solution. In order to prevent oxidation, the ferrous sulfate solution needs to be prepared and used immediately.

[0052] Measure 200mL of potassium permanganate and 400mL of ferrous sulfate solution, pour 200mL of potassium permanganate solution into a 1000mL beaker, and add 80.1g at the same time (because ceramsite is not a powder, it is difficult to weigh the integer mass in the actual weighing process) . The volcanic rock ceramsite after drying similarly with embodiment 1, prepare mechanical stirrer above the beaker.

[0053] Start stirring at room temperature, slowly add 400mL ferrous sulfate solution, and adjust the pH of the mixed solution to about 10 with 5mol / L sodium hydroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com