Organic waste gas adsorption recovery device

A technology for adsorption recovery and organic waste gas, which is applied in the direction of combustible gas purification, combustible gas purification/renovation, filter regeneration, etc., can solve the problems of reducing the efficiency of removing additional work, increasing the cost of additional work, and achieving low cost of removing additional work. , The effect of high desorption recovery efficiency and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

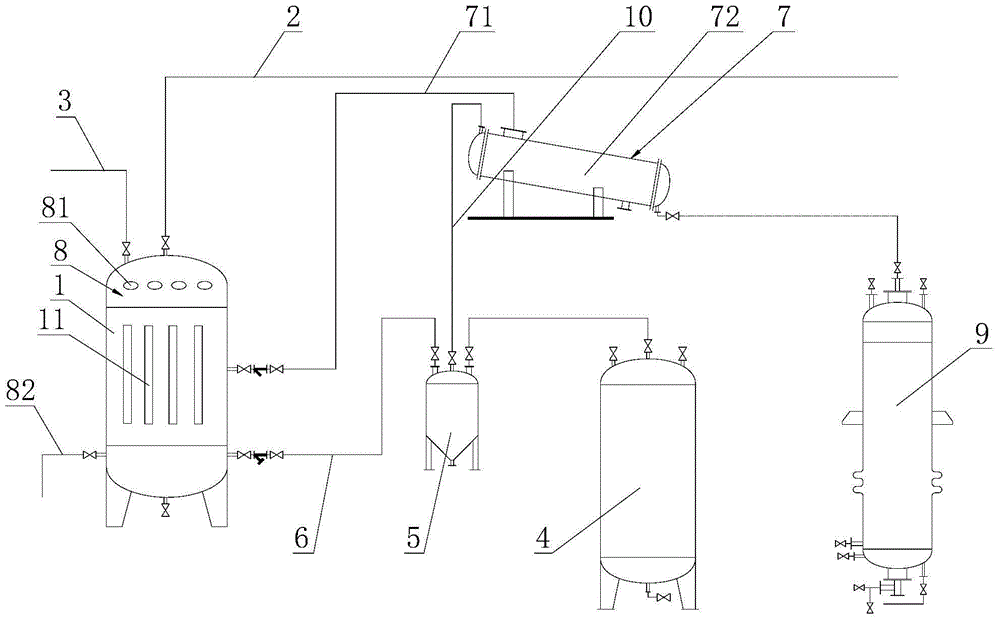

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] see figure 1 As shown, the above-mentioned organic waste gas adsorption and recovery device includes an adsorption tank 1 for absorbing organic matter in the organic waste gas, a waste gas delivery pipe 2 for passing organic waste gas into the adsorption tank 1, and a waste gas delivery pipe 2 for outputting the organic waste gas through the adsorption tank 1. Purified gas conveying pipe 3 for adsorbed and purified gas. The adsorption material in the adsorption tank 1 is activated carbon 11, and the adsorption recovery device also includes a nitrogen generating mechanism 4, a heating mechanism 5 communicating with the nitrogen generating mechanism 4 for heating the obtained nitrogen, communicating with the heating mechanism 5 and The adsorption tank 1 is used to pass into the first delivery pipe 6 of high-temperature nitrogen in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com