A waste cigarette shredded tobacco recovery equipment

A technology for recycling equipment and waste cigarettes, which is applied in the fields of tobacco, paper cigarette manufacturing, application, etc., can solve the problems of high labor intensity, large residual volume and high density of cut tobacco in cigarettes, so as to improve the recovery rate of cut tobacco, improve labor productivity, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

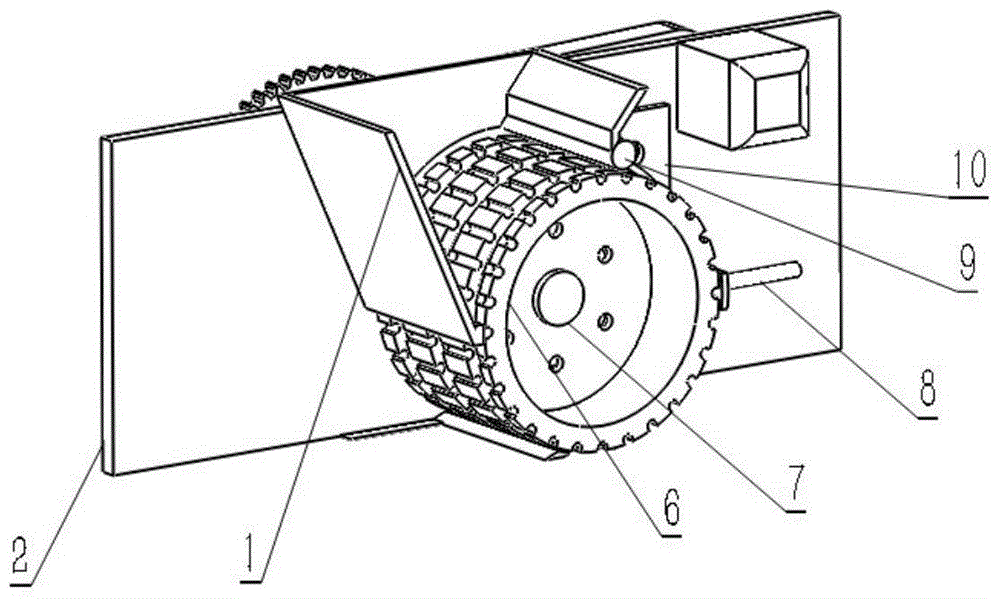

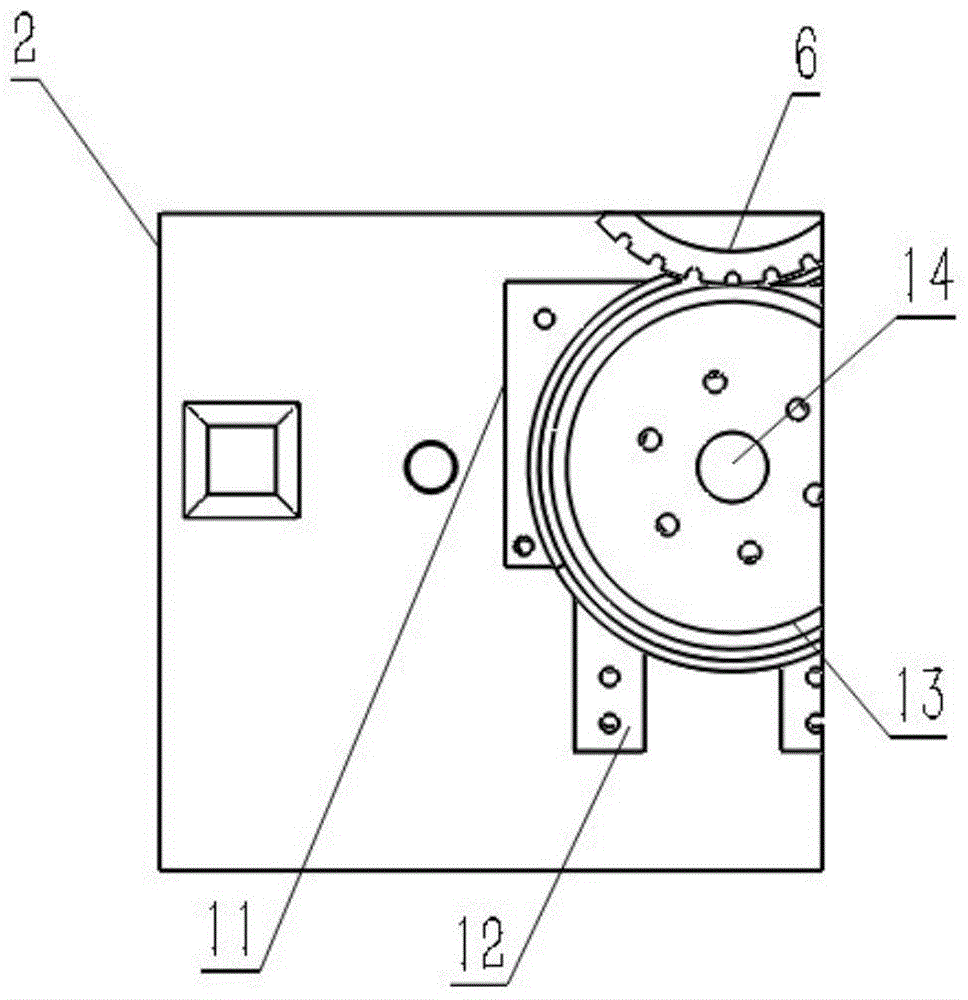

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 The shown waste cigarette shredded tobacco recycling equipment includes a frame 2, a cigarette rack 1, a driving device A27, a driving device B26, a cigarette grabbing device 3, a cigarette tight end evacuation device 4 and a shredded tobacco separating device 5 , the cigarette storehouse 1, the cigarette grabbing device 3, the cigarette tight head evacuation device 4 and the shredded tobacco separation device 5 are respectively installed in front of the frame 2, the cigarette storehouse 1, the cigarette grabbing device 3. The evacuation device 4 and the shredded tobacco separation device 5 are sequentially connected. The cigarette storehouse 1 is located at the upper left of the frame 2, and the cigarette grabbing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com