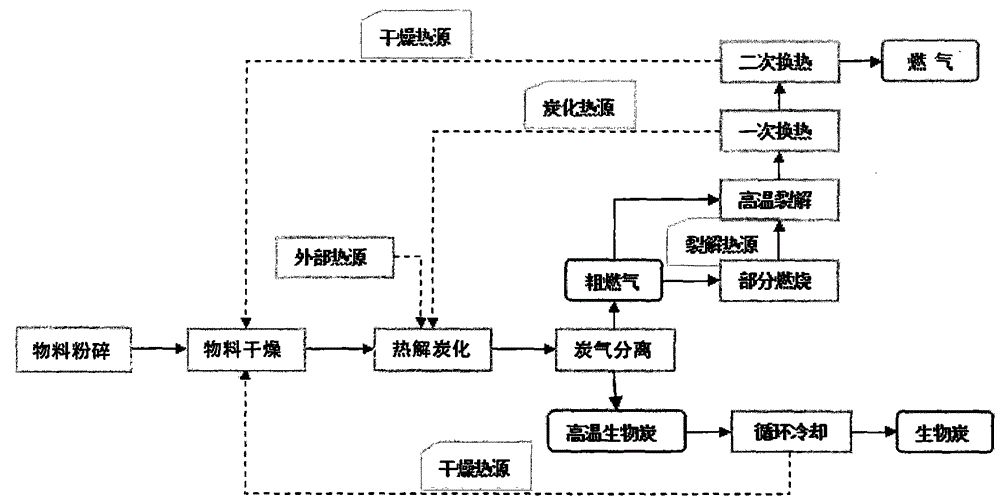

Closed pyrolysis carbonization poly-generation process

A technology of pyrolysis carbonization and polygeneration, which is applied in the petroleum industry, special forms of dry distillation, direct heating dry distillation, etc., can solve the problems of imperfect production process, large heat loss, high energy consumption, etc., to reduce external energy input, Effect of reducing heat waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Example: Using corn stalks to produce co-produced biochar and gas

[0023] A closed-type pyrolysis and carbonization multi-process of the present invention is used to produce biochar. The raw material is corn stalks, and the raw material is loaded into the hopper. The length of the material after crushing is about 3-4 mm, and the moisture content of the material after drying is 10-20%. between. The start-up of the external power supply provides a heat source for the pyrolysis and carbonization of the material in the initial stage of work, so that the material is pyrolysis and carbonization at high temperature, and the products of pyrolysis and carbonization are high-temperature biochar and crude gas. Then, in the carbon gas separation process, the high-temperature biochar and crude gas are separated, and are refined through the line I and line II respectively, and the high-temperature biochar separated by the line I is circulated and cooled to obtain cooled biochar suit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com