Hydrate Accelerator and Its Application in Preparation of High Gas Storage Density Gas Hydrate

A gas hydrate and accelerator technology, applied in gas fuel, other chemical processes, petroleum industry, etc., can solve the problems of increasing the formation rate of gas hydrate, negative impact on the environment, high cost, etc., and shorten the hydration induction time, method Fast, increase the effect of gas storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A hydrate accelerator is an amino acid aqueous solution with a mass fraction of 0.5%, which is uniformly mixed with 99.5 grams of water, 0.3 grams of leucine and 0.2 grams of phenylalanine.

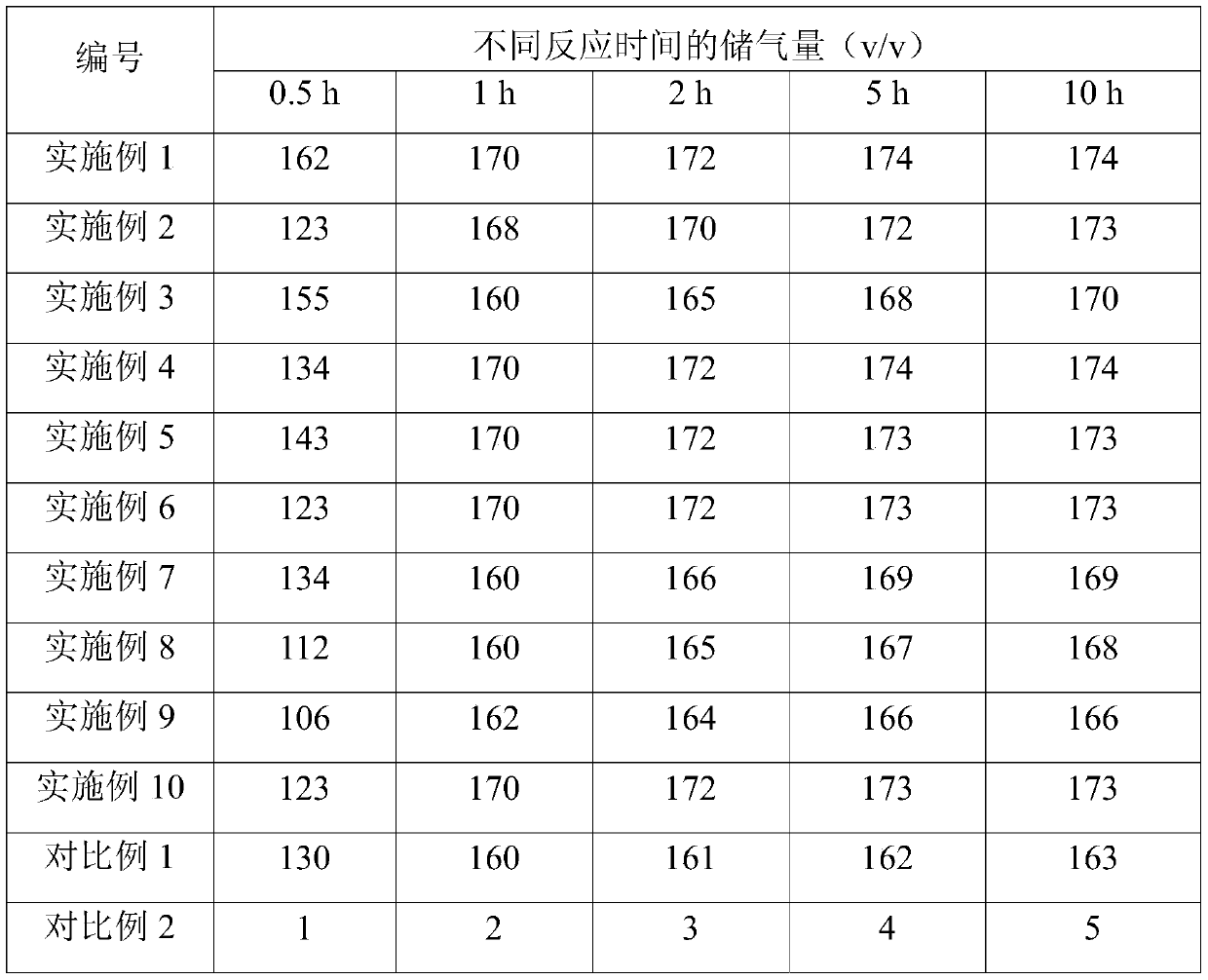

[0020] A method for rapidly preparing gas hydrates with high gas storage density: fill 100 grams of the above-mentioned amino acid aqueous solution into 100 grams of the above-mentioned amino acid aqueous solution at 0 ° C in an autoclave (the effective volume of the autoclave is 500 mL), and charge methane gas with a pressure of 9.5 MPa, Under the action of amino acid promoters, solid hydrates with high gas storage density were rapidly grown to form, and the gas storage volume was recorded at a certain time interval. The results are shown in Table 1, where the hydration induction time is 4 minutes.

Embodiment 2

[0022] A hydrate accelerator is an amino acid aqueous solution with a mass fraction of 1%, which is uniformly mixed with 99 grams of water, 0.5 grams of leucine and 0.5 grams of valine.

[0023] A method for rapidly preparing gas hydrates with high gas storage density: fill 100 grams of the above-mentioned amino acid aqueous solution into 100 grams of the above-mentioned amino acid aqueous solution at 0 ° C, and charge methane gas with a pressure of 8.5 MPa in the The solid hydrate with high gas storage density was rapidly grown under the action, and the gas storage volume was recorded at a certain time interval. The results are shown in Table 1, where the hydration induction time is 5 minutes.

Embodiment 3

[0025] A hydrate accelerator is an amino acid aqueous solution with a mass fraction of 0.2%, which is uniformly mixed with 99.8 grams of water, 0.1 grams of phenylalanine and 0.1 grams of isoleucine.

[0026] A method for rapidly preparing gas hydrates with high gas storage density: 100 grams of the above-mentioned amino acid aqueous solution in a high-pressure reactor ((effective volume 500mL)) at 0°C is filled with methane gas with a pressure of 9.5 MPa, and the amino acid accelerator The solid hydrates with high gas storage density were rapidly grown under the action of , and the gas storage volume was recorded at a certain time interval. The results are shown in Table 1, where the hydration induction time is 8 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com