Prepreg, carbon-fiber-reinforced composite material, and robot hand

A technology of carbon fiber and prepreg, applied in thin material processing, synthetic resin layered products, transportation and packaging, etc., can solve the unsatisfactory fiber-reinforced composite materials and other problems, and achieve excellent heat resistance and saturated water absorption Low rate and excellent deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0086] As the (a1) component, 40 parts by mass of the product name Primaset PT-60 (manufactured by Lonza Corporation) and 20 parts by mass of the product name Primaset PT-30 (manufactured by Lonza Corporation) of a novolak type cyanate resin, and 40 parts by mass of the trade name Primaset BA-200 (manufactured by Lonza Corporation) of bisphenol-type cyanate resin, and 0.06 parts by mass of Co(acac) as the component (a2) 3 3 parts by mass of polyethersulfone (trade name ULTRASON E 2020P SR MICRO, manufactured by BASF Corporation) as the component (a3) was mixed with a planetary mixer to prepare the resin composition (a), and then coated on the release paper A precursor film is thus obtained. Next, a carbon fiber with a tensile modulus of elasticity of 780 GPa (trade name XN-80, manufactured by Nippon Graphite Fiber Co., Ltd.) was made into a unidirectional sheet, and the above-mentioned precursor film was heated and pressed, and immersed in the unidirectional sheet. In the s...

Embodiment 2-1

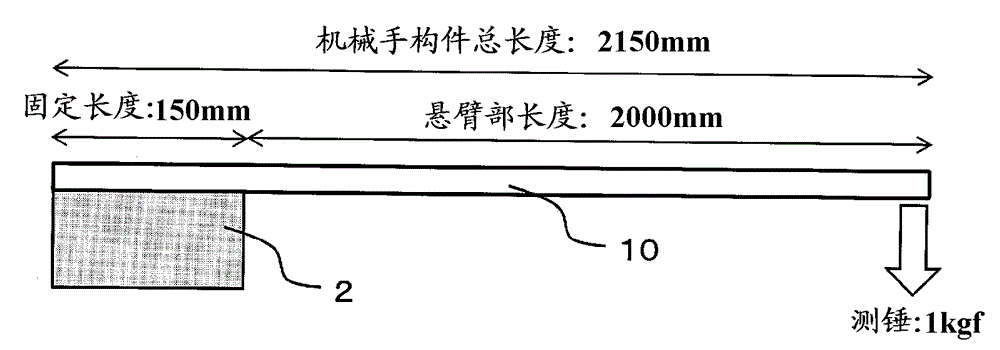

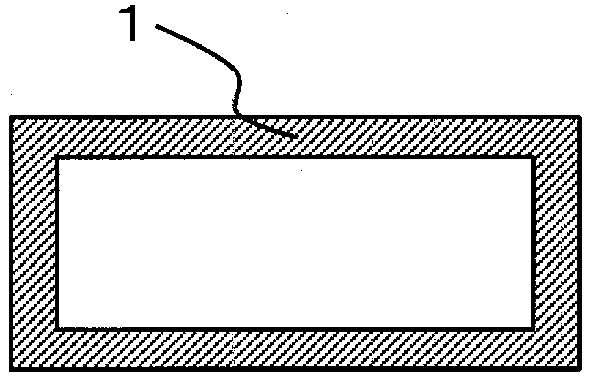

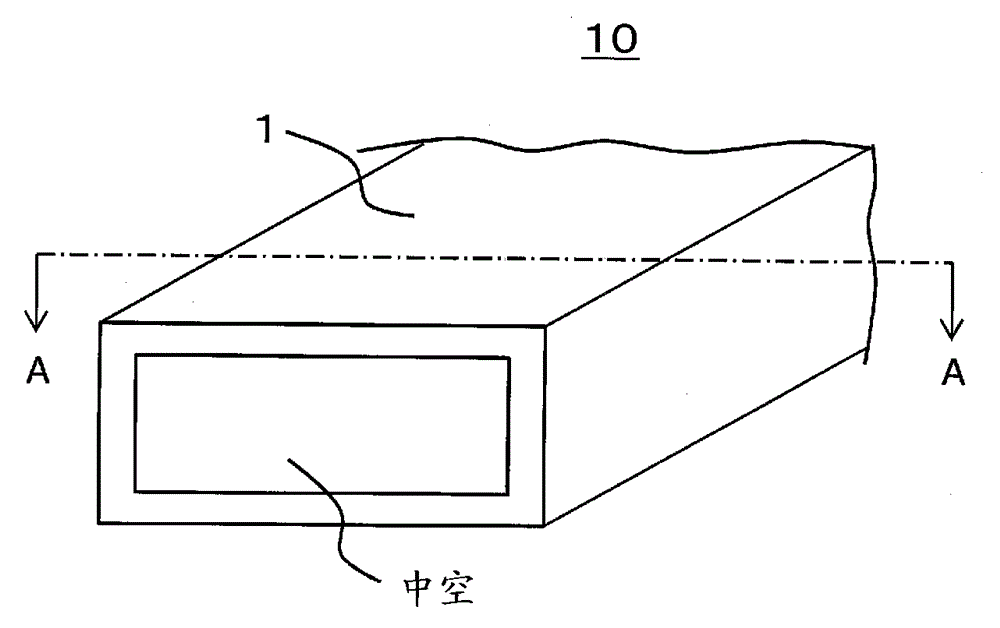

[0113] Using the resin composition (a) prepared in Example 1-1 and the carbon fibers (CF) shown in Table 2, CFRP sheets PPG-A and PPG-E shown in Table 2 were produced. Next, by winding them around a mandrel, a prepreg having a laminate structure shown in Table 3 was manufactured. Next, it is heated and cured under the condition of 180°C×4 hours to manufacture a image 3 Dimensions shown are for a manipulator with an open cross-section and an overall length of 2150 mm. The following bending rigidity test was performed on the obtained manipulator. The results are shown in Table 3.

[0114] It should be noted that, in Table 3, "0°" of the CF orientation angle means that the carbon fibers are oriented in the length direction of the manipulator, and "0° / 90°" means that the carbon fibers are oriented in the length direction and the direction perpendicular to the length direction. Directional oriented plain weave.

[0115] Bending stiffness test

[0116] like Figure 4 As shown...

Embodiment 2-2、2-3 and comparative example 2-1

[0118] A manipulator was produced in the same manner as in Example 2-1 except that the laminate structure of the CFRP sheet and prepreg used was the structure shown in Table 3, and the bending rigidity was performed in the same manner as in Example 2-1. test. The results are shown in Table 3. In addition, PPG-B, PPG-C, and PPG-D in Table 3 were manufactured similarly to PPG-A of Example 2-1 except having used the CF shown in Table 3.

[0119] [Table 2]

[0120]

[0121] *1 Asphalt type, tensile modulus of elasticity: 780GPa, manufactured by Nippon Graphite Fiber Co., Ltd.

[0122] *2 Asphalt type, tensile modulus of elasticity: 620GPa, manufactured by Nippon Graphite Fiber Co., Ltd.

[0123] *3 PAN type, tensile modulus of elasticity: 455GPa, manufactured by Mitsubishi Rayon Co., Ltd.

[0124] *4 Asphalt type, tensile modulus of elasticity: 230GPa, manufactured by Toray Industries Inc.

[0125] *5 PAN type, plain weave fabric, tensile modulus of elasticity: 230 GPa, ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com