Mechanical device for producing amino acid organic compound fertilizer

A mechanical device and amino acid technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of low nutrient content and many germs, and achieve the effects of improving quality, simple production process, and improving fertilizer utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

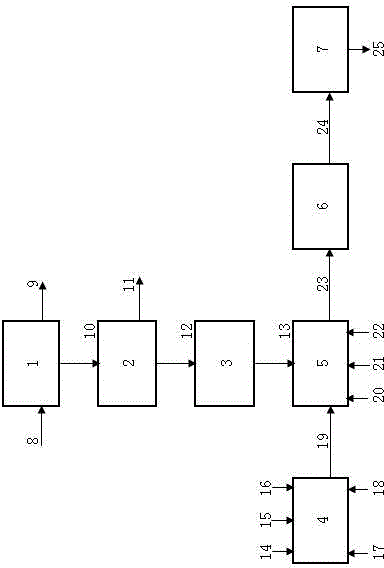

[0012] Further illustrate the specific content of using this device to produce the best embodiment of amino acid organic compound fertilizer below in conjunction with accompanying drawing:

[0013] 1. The amino acid waste liquid is sent to the filter 1 through the amino acid waste liquid inlet 8 arranged on the filter 1 to filter out impurities, and the filtered impurities are discharged through the impurity outlet 9 arranged on the filter 1 to remove the amino acid waste of impurities The liquid is sent to the centrifuge 2 for separation and desalination through the first slurry pump and the pipeline 10 arranged between the filter 1 and the centrifuge 2, and the removed centrifuge passes through the centrifuge outlet arranged on the centrifuge 2 11 is discharged, and then the clean amino acid waste liquid is sent to the concentration tank 3 through the second slurry pump and the pipeline 12 arranged between the centrifuge 2 and the concentration tank 3 for concentration, until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com