Sewage impurity separation method

A separation method and impurity technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of equipment short-term treatment capacity decline and reduce equipment investment, installation and The effect of convenient maintenance, reduced operating energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

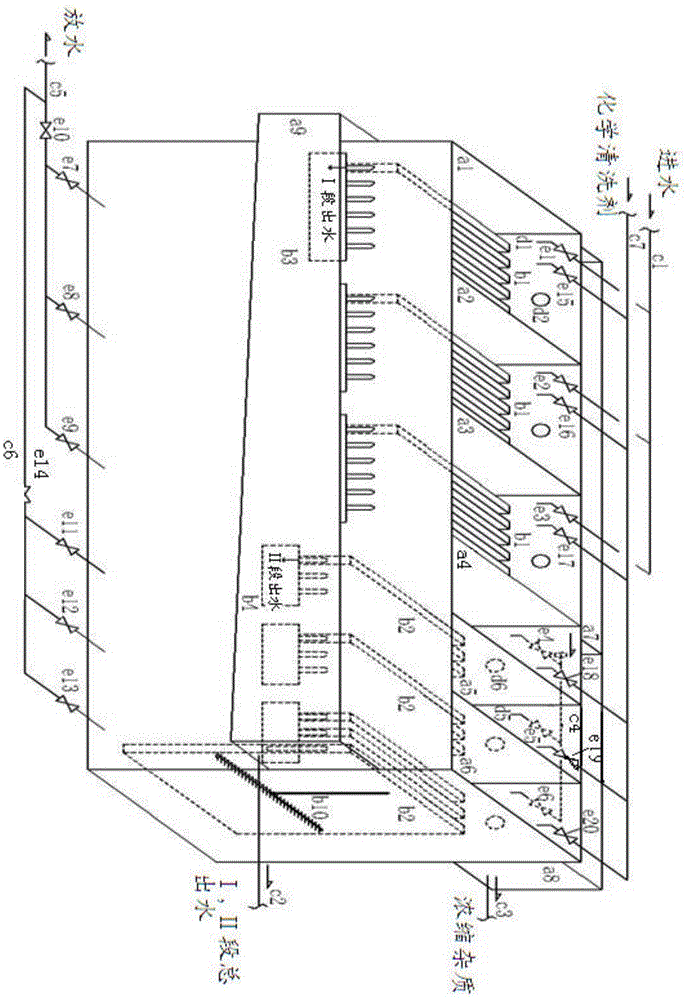

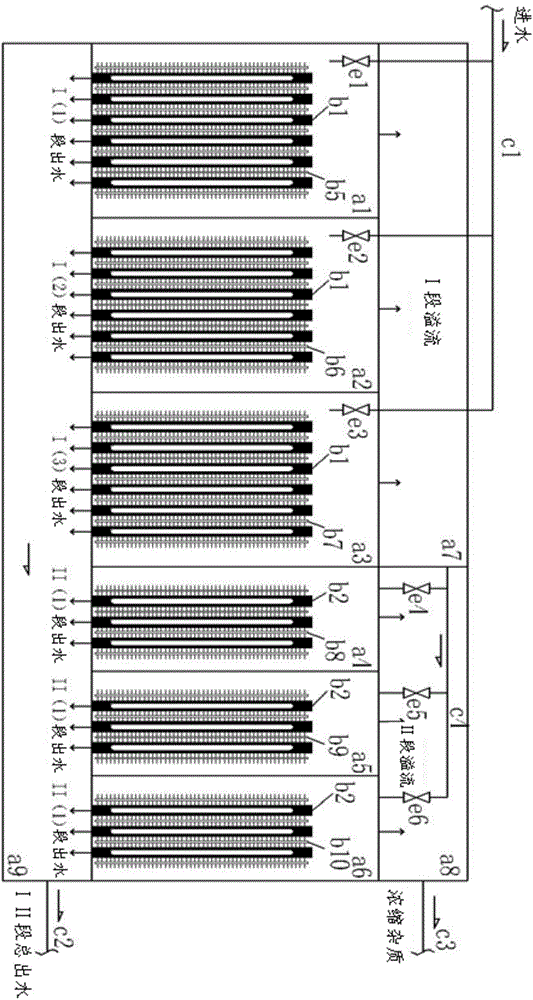

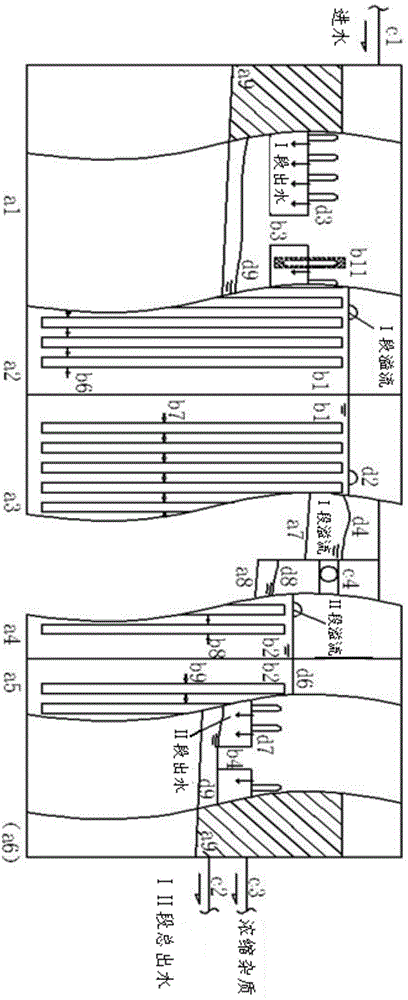

[0030] Figure 1~3 As shown, in this embodiment, the main reactor is divided into two sections, and each section is connected with three grid reactors in parallel as an example. The three grid reactors connected in parallel in section I are a1, a2, a3, and the three grid reactors connected in parallel in section II are a4, e5, a6. In section I, flat micro-grid component b1 is set, and in section II, flat micro-grid component b2 is set. , the water inlet pipe c1 is respectively connected with the water inlet valves e1, e2, and e3 of section I, and is set on the upper part of the reactors a1, a2, and a3; , e8, and e9 are connected to the reactors a1, a2, and a3 respectively, and the vent pipe c6 at the bottom of section II is connected to the vent valve e14 of section II, and connected to the connecting valves e11, e12, and e13. They are connected with reactors a4, a5 and a6 respectively. The chemical cleaning pipe c7 is respectively connected with the chemical cleaning valves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com