Grid-type logistics tray and manufacturing method thereof

A manufacturing method and grid-based technology, applied in the direction of sustainable manufacturing/processing, biological packaging, rigid containers, etc., can solve the problems of lack of grid-type logistics tray protection, environmental protection, single function, etc., and achieve easy modularization The effect of reducing production, reducing usage, and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] figure 1 It is a schematic diagram of the bamboo chip structure of the present invention. (01) in the picture is a bamboo chip with a long strip shape. There are many horizontal installation holes (02) on the bamboo chip. There are single-layer dry bamboo chips (03), double-layer composite dry bamboo chips (04) and multiple The multi-layer composite dry bamboo chip (05) has various structures, and the double-layer or multi-layer composite dry bamboo chip is formed by bonding and compounding the single-layer dry bamboo chip (03) with an environmentally friendly glue (06).

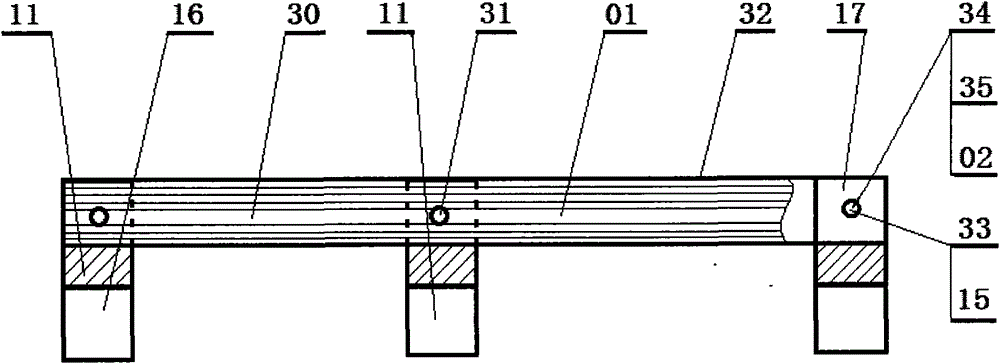

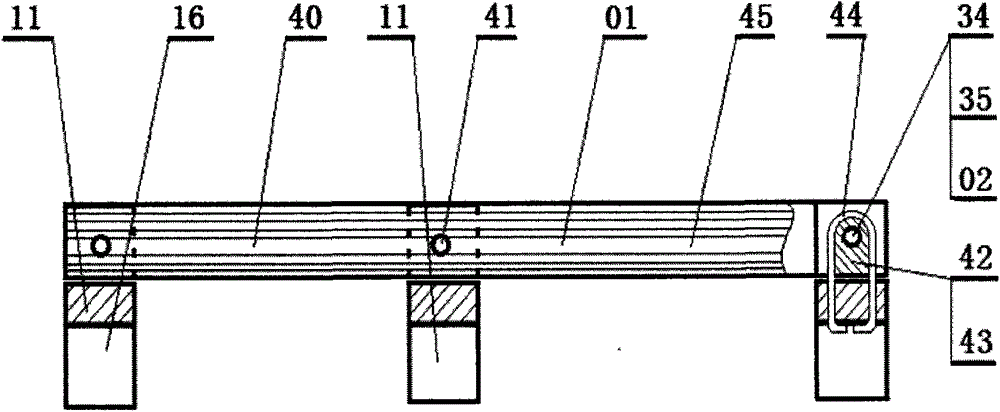

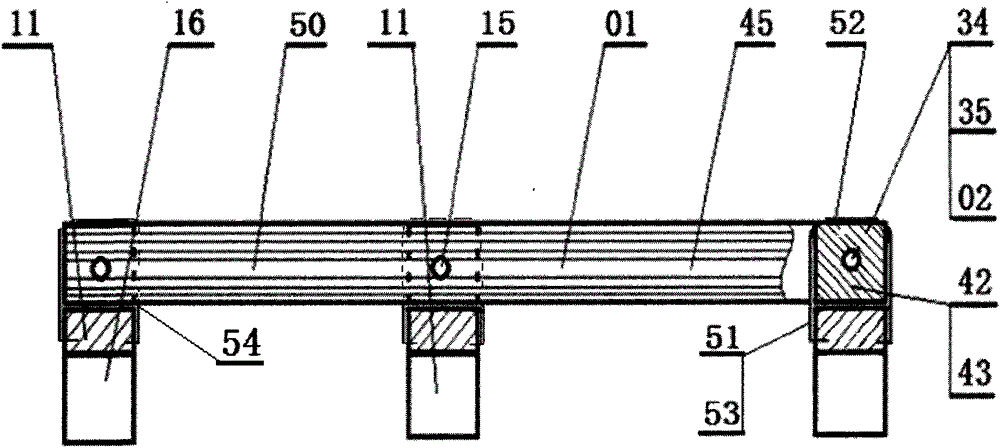

[0025] figure 2 It is a structural schematic diagram of the pallet foot of the present invention. (10) in the picture is the tray foot, which is column-shaped in appearance and has a variety of horizontal tray feet (11), vertical tray feet (12), vertical tray feet B (13) and swivel casters (14) structure. The horizontal pallet foot (11) has a rectangular cross-section and is installed horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com