Crawler type slicing machine

A crawler-type, planing technology, applied in the manufacture of veneer, wood processing appliances, manufacturing tools, etc., can solve the problems of wasting electric energy, consuming a lot of power, and product specification sheets, achieving simple equipment structure and guaranteeing output. Demand and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

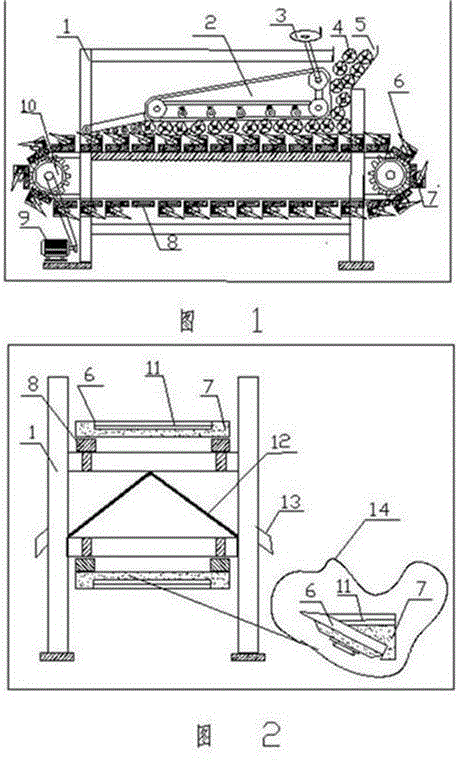

[0033] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples.

[0034] When implementing and using, the long raw material is cut into 380mm long wood section on the cutting machine earlier, then the wood section is sent into the raw material inlet 5 of the crawler-type planer of the present invention by the conveyor, as Figure 1 to Figure 2 Shown:

[0035] 1_ is the body of the present invention, 2_ is the pressing mechanism of the present invention, the pressing mechanism is not equipped with a transmission device and a surrounding chain, and there are multiple springs on the chain, the effect is to hold down the raw material and prevent it from being planed. When jumping, and help the wood section to run forward, the elastic chain is suitable for log sections of different diameters and sizes.

[0036] 3_ is the adjusting device of the pressing mechanism, which is used to adjust the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com