An automatic control system for drying with steam condensed water as a heat source and its realization method

An automatic control system, steam condensate technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of waste of energy, high production costs, etc., to reduce the loss of waste products, improve the quality of castings, and improve the quality of drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

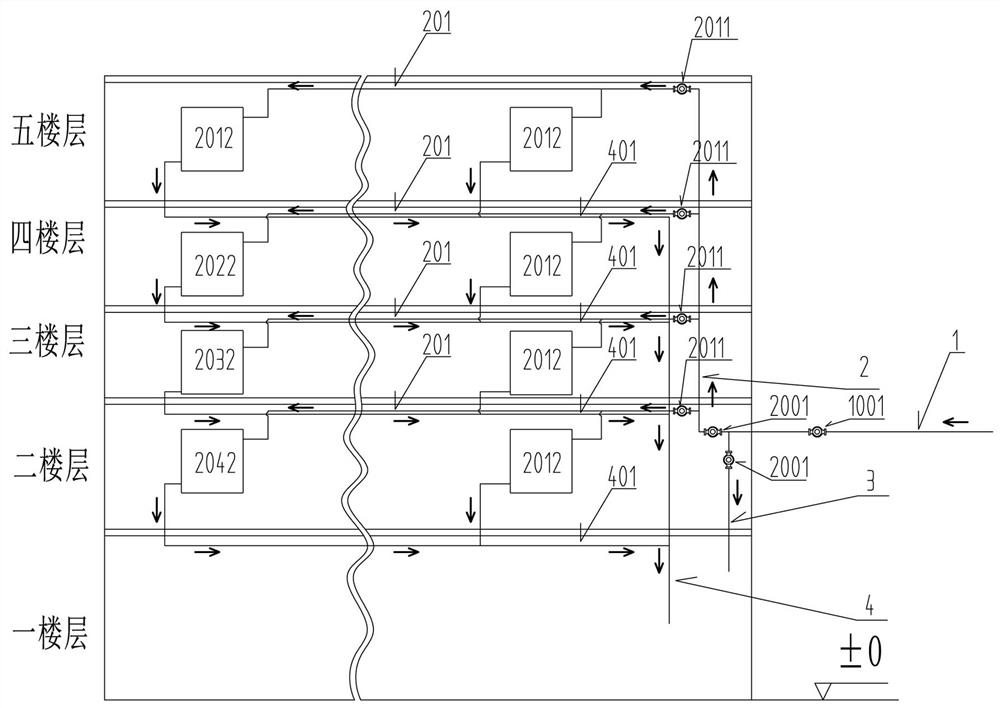

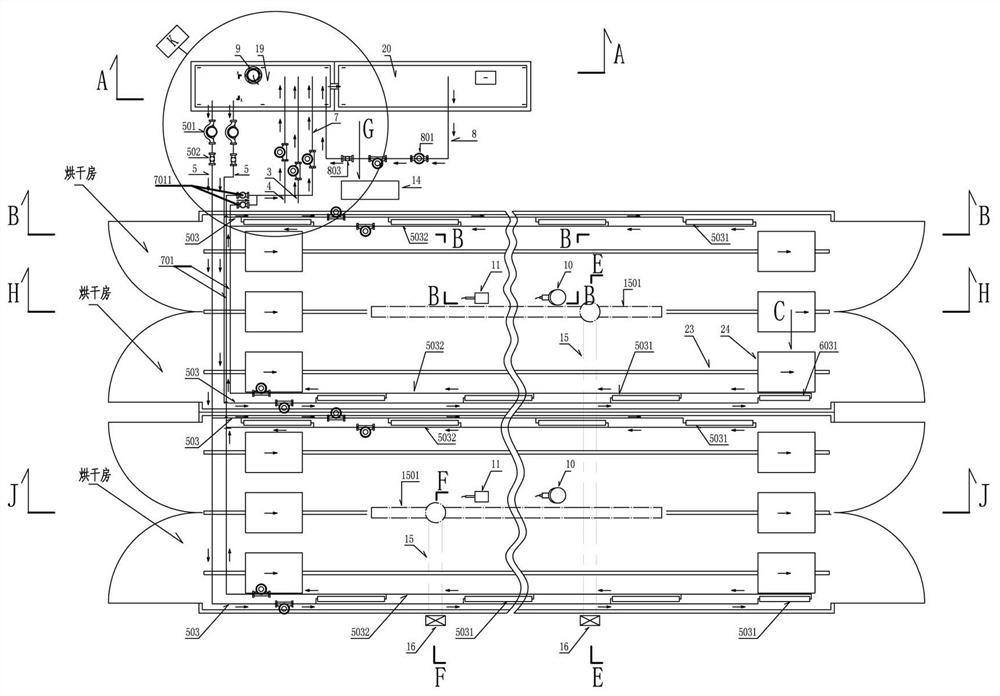

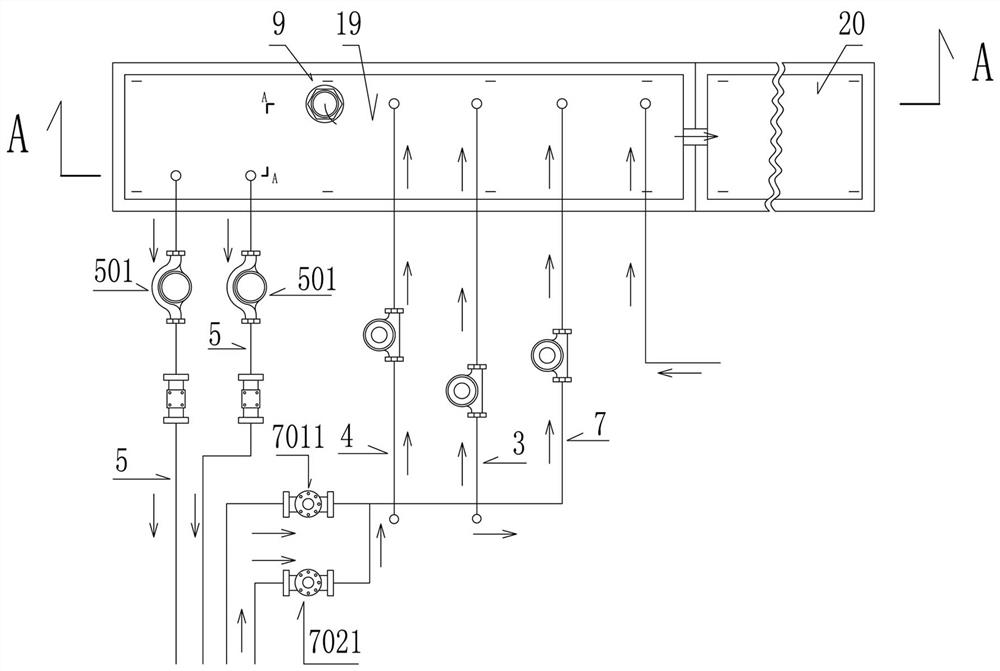

[0046] Example 1, as Figure 1 to Figure 10 As shown, a drying automatic control system using steam condensate as heat source, the control system is an automatic control system that uses its steam condensate and residual steam as radiator heat source to dry white molds and yellow molds

[0047] The control system includes a main pipeline 1 and an electronic electric actuator 1001. The main pipeline 1 is connected with a pipeline 2 and a steam branch pipeline 3. A steam ball valve 2001 is arranged between the pipeline 2, the steam branch pipeline 3 and the main pipeline 1, and the steam passes through. The main pipeline 1 enters the workshop and is controlled by the electronic electric actuator 1001. After passing through the electronic electric actuator 1001, the steam is divided into two paths. One is to supply steam to the workshop on the second to fifth floors through the pipeline 2, and the other is to pass the steam branch pipeline. 3 Supply steam to the condensate reserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com