Nanometer bead milling system and nanocrystalline microsphere preparation method

A technology of nanocrystalline microspheres and nanobeads, which is applied in the direction of grain processing, etc., can solve the problems of unreasonable design of the grinding chamber, affecting the dispersion effect of the powder pulverizer, continuous output, etc., and achieves controllable and improved quality indicators. Apparent surface area, effect of increasing product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

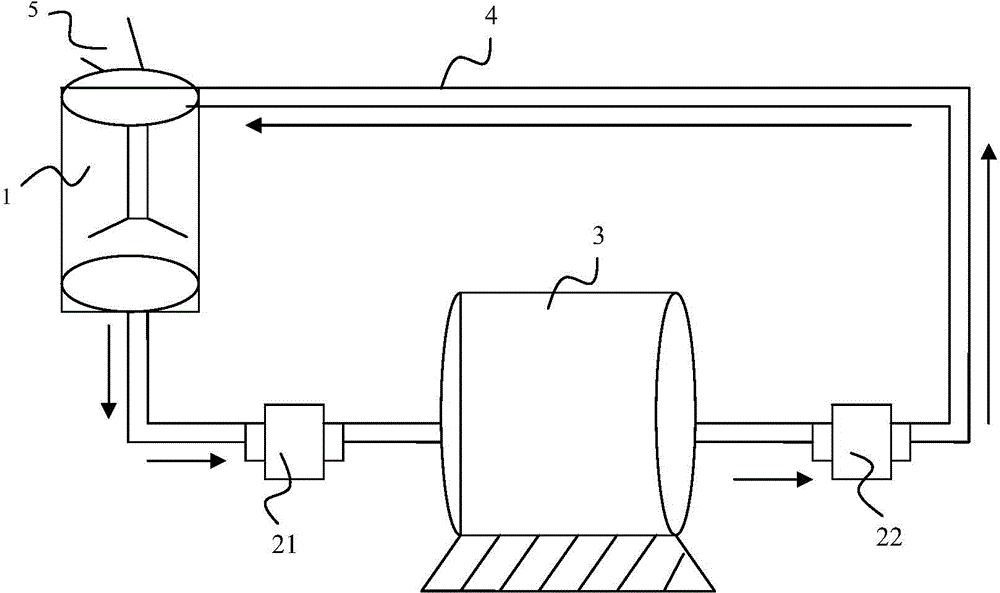

[0028] figure 1 It is a schematic diagram of the structure of the nano-bead milling system of the present invention.

[0029] See figure 1 , the nano bead milling system provided by the present invention comprises a stirring tank 1, a bead mill 3, a first pump 21 and a second pump 22, the outlet of the stirring tank 1 is connected to the inlet of the first pump 21 through a pipeline 4, and the first The outlet of the pump 21 is connected to the inlet of the bead mill 3 through a pipeline, the outlet 38 of the bead mill is connected to the inlet of the second pump 22 through the pipeline 4, and the outlet of the second pump 22 is connected to the inlet of the stirring tank 1 through the pipeline 4 connected.

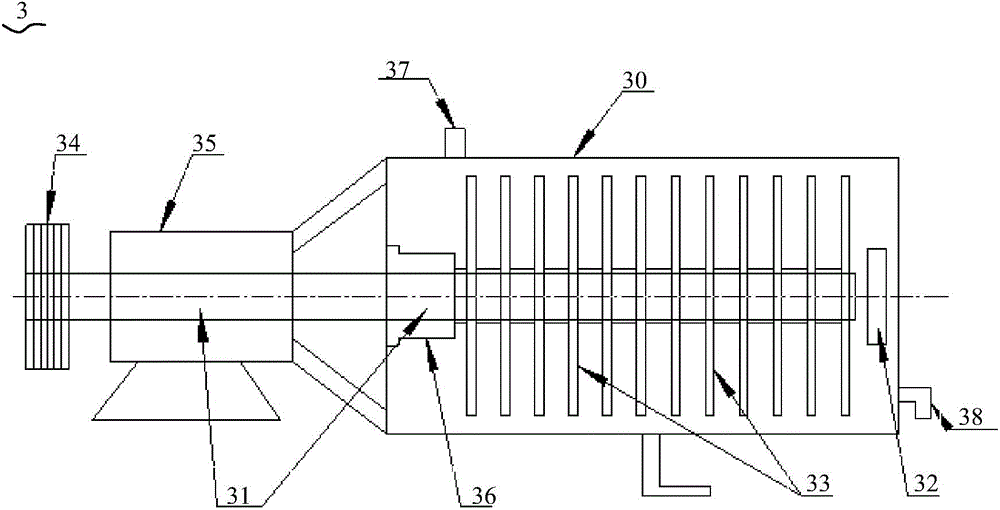

[0030] figure 2 It is a schematic structural diagram of the nano bead mill in the embodiment of the present invention.

[0031] See figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com