Catalyst for continuously preparing N-isopropyl-4-fluoroanilines, and preparation method and application of catalyst

A technology of catalyst and fluoroaniline, which is applied in the field of catalyst and preparation for continuous preparation of N-isopropyl-4-fluoroaniline, can solve the problems of difficult post-processing, lack of market competitiveness in technology and economy, and high reaction requirements, and achieve High catalytic activity and stability, good market promotion prospects, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

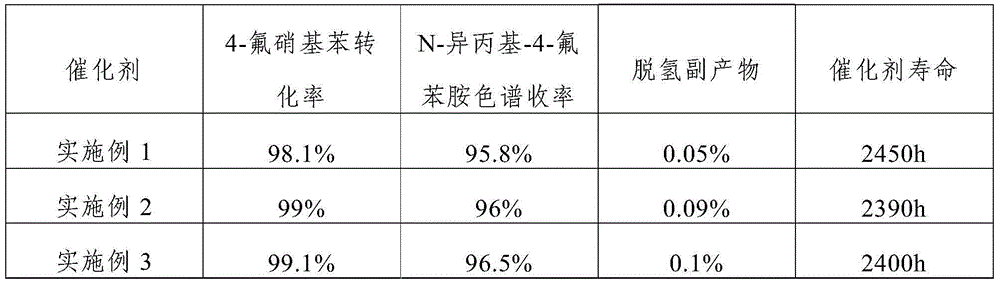

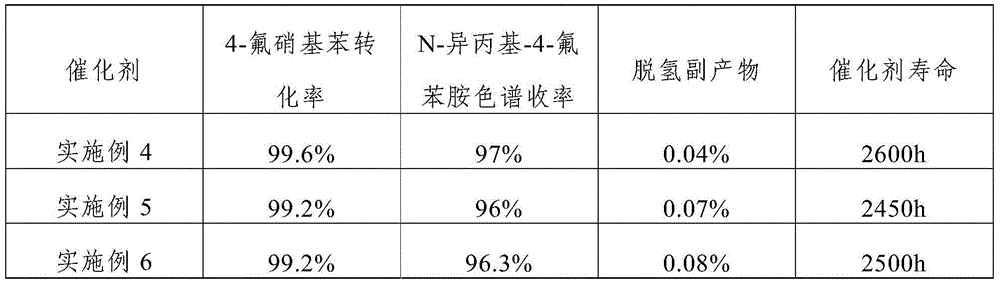

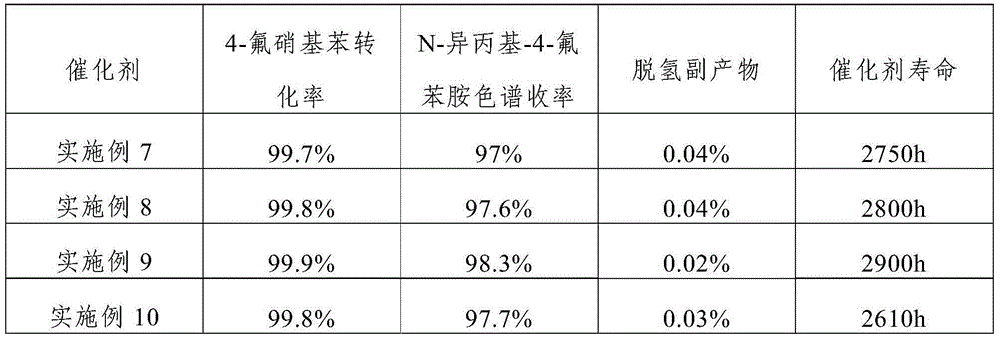

Examples

Embodiment 1

[0037] The catalyst of the present embodiment includes activated carbon carrier, Pt, Fe and K loaded on the activated carbon carrier; the mass percentage of Pt in the catalyst is 0.3%, the mass percentage of Fe is 0.05%, and the mass percentage of K The content is 0.05%; the average particle diameter of the activated carbon carrier is 1.0mm, and the specific surface area is 920m 2 / g.

[0038] The preparation method of the catalyst of the present embodiment is:

[0039] Step 1, dissolving chloroplatinic acid containing 0.3g of platinum in dilute nitric acid with a mass concentration of 0.8%, to obtain solution A;

[0040] Step 2, dissolving ferric chloride containing 0.05g iron in dilute nitric acid with a mass concentration of 1%, to obtain solution B;

[0041] Step 3. Mix the solution A described in step 1 and the solution B described in step 2 evenly to obtain solution C. Soak 99.6g of activated carbon carrier in solution C, heat to 40°C, keep warm and ultrasonic for 2 ho...

Embodiment 2

[0047] The catalyst of the present embodiment includes activated carbon carrier, Pt, Sn and Ce loaded on the activated carbon carrier; the mass percentage of Pt in the catalyst is 0.5%, the mass percentage of Sn is 0.25%, and the mass percentage of Ce is The content is 0.25%; the average particle diameter of the activated carbon carrier is 0.5mm, and the specific surface area is 1180m 2 / g.

[0048] The preparation method of the catalyst of the present embodiment is:

[0049] Step 1, dissolving chloroplatinic acid containing 0.5g of platinum in dilute nitric acid with a mass concentration of 0.5%, to obtain solution A;

[0050] Step 2, dissolving stannous chloride containing 0.25g tin in dilute nitric acid with a mass concentration of 0.5%, to obtain solution B;

[0051] Step 3. Mix the solution A described in step 1 and the solution B described in step 2 evenly to obtain solution C. Soak 99g of activated carbon carrier in solution C, heat it to 35°C, keep it warm and ultras...

Embodiment 3

[0057] The catalyst of the present embodiment comprises activated carbon carrier, Pt, Cu and Ce loaded on the activated carbon carrier; the mass percent composition of Pt in the described catalyst is 1.0%, the mass percent composition of Cu is 0.5%, the mass percent composition of Ce The content is 0.5%; the average particle diameter of the activated carbon carrier is 1.5mm, and the specific surface area is 810m 2 / g.

[0058] The preparation method of the catalyst of the present embodiment is:

[0059] Step 1, dissolving chloroplatinic acid containing 1.0 g of platinum in dilute nitric acid with a mass concentration of 1.2%, to obtain solution A;

[0060] Step 2, dissolving copper nitrate containing 0.5g copper in dilute nitric acid with a mass concentration of 1.2%, to obtain solution B;

[0061] Step 3. Mix the solution A described in step 1 and the solution B described in step 2 evenly to obtain solution C. Soak 98g of activated carbon carrier in solution C, heat it to 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com