Efficient oxidation catalyst for diesel vehicle tail gas purification and preparation method and application thereof

An oxidation catalyst and tail gas purification technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high-cost promotion of noble metal-based catalysts and easy generation of catalytic activity Sulfate, low catalyst activity and other problems, to achieve the effect of excellent reusability, excellent resistance to water vapor poisoning, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Weigh 0.007mol potassium permanganate and 0.003mol cerium nitrate hexahydrate, and dissolve them in 40mL deionized water under stirring in a water bath at 80°C to form a uniform solution; measure 10mL hydrogen peroxide and add dropwise to the above homogeneous solution After 12 hours of oxidation-reduction reaction, vacuum filtration, washing with a large amount of water, drying in an oven at 80°C to obtain a precursor, calcining in a muffle furnace at 550°C for 4 hours to obtain a non-precious metal mesoporous composite oxide catalyst, Recorded as: Ce-Mn.

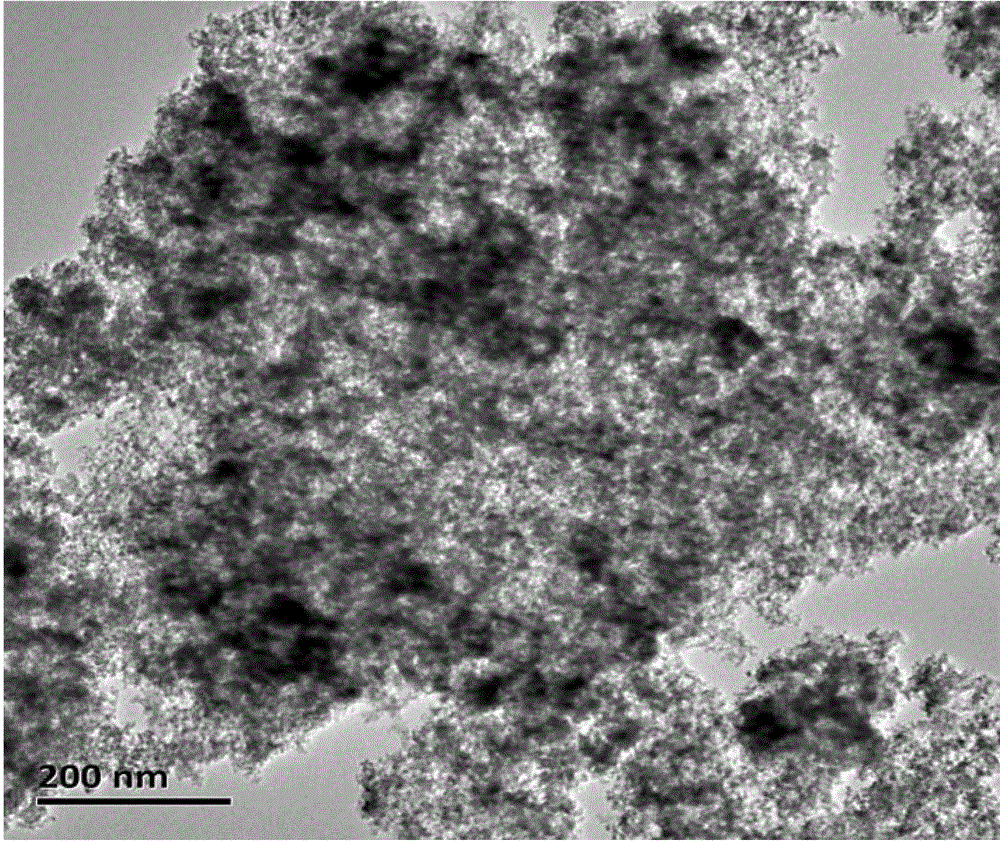

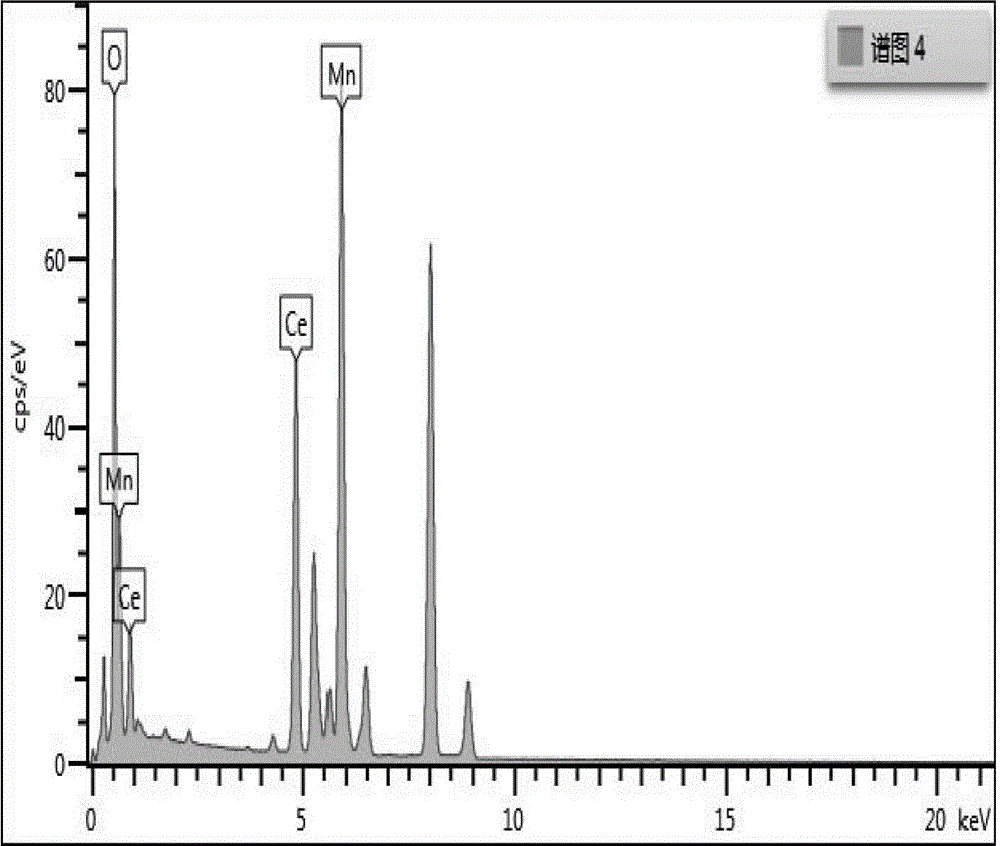

[0056] Figure 1a and Figure 1b For the prepared CeMnO of this embodiment x TEM and EDS photos of the catalyst. Depend on Figure 1a and Figure 1b It can be seen that the material has a good pore structure, and the prepared material contains elements Mn, Ce and O.

Embodiment 2

[0058] Weigh 0.005mol of copper acetate, 0.01mol of manganese acetate and 0.005mol of cerium nitrate, and dissolve them in 50mL of deionized water while stirring in a water bath at 40°C to form a uniform solution; measure 20mL of hydrogen peroxide and add it dropwise to the above homogeneous solution And keep stirring, after reacting for 12 hours, vacuum filtration, washing with a large amount of water, drying in an oven at 60°C to obtain a precursor, and calcining in a muffle furnace at 550°C for 4 hours to obtain a non-precious metal mesoporous composite oxide catalyst, which is recorded as: Cu-Mn-Ce.

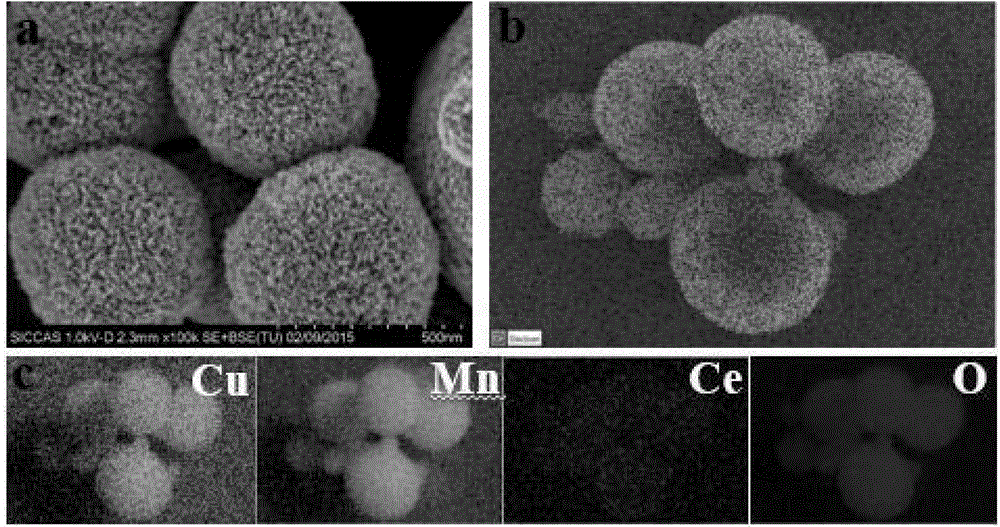

[0059] figure 2 It is the SEM and elemental distribution diagram of the Cu-Mn-Ce catalyst prepared in this example. Depend on figure 2 It can be seen that the material has a good pore structure, and the elements Mn, Cu, Ce and O are uniformly distributed throughout the material.

Embodiment 3

[0061] A synthesis process similar to that of Example 2 was adopted, except that 0.0015 mol of zirconium nitrate was added to the precursor solution to prepare a Cu-Mn-Ce-Zr mesoporous composite oxide catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com